Custom Plasma Cutting Service

Experience precision and quality like never before with our custom plasma cutting service. We use the latest technology to ensure the highest level of accuracy and consistency.

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

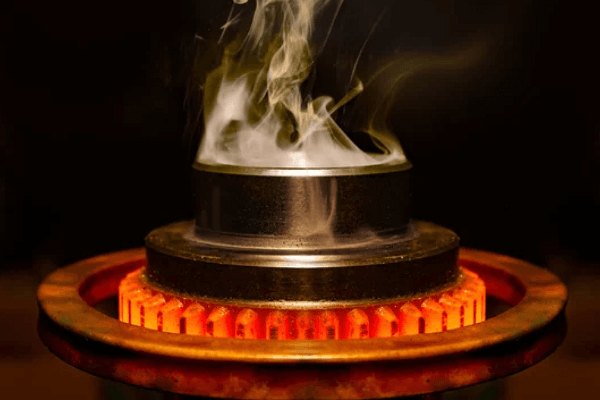

What Is Plasma Cutting Service

Our Plasma Cutting Service delivers high-speed, high-precision cutting for a wide range of metals. Using advanced plasma technology, we achieve superior cut quality, minimal kerf loss, and high production throughput for various industrial applications.

Applications of Plasma Cutting Parts

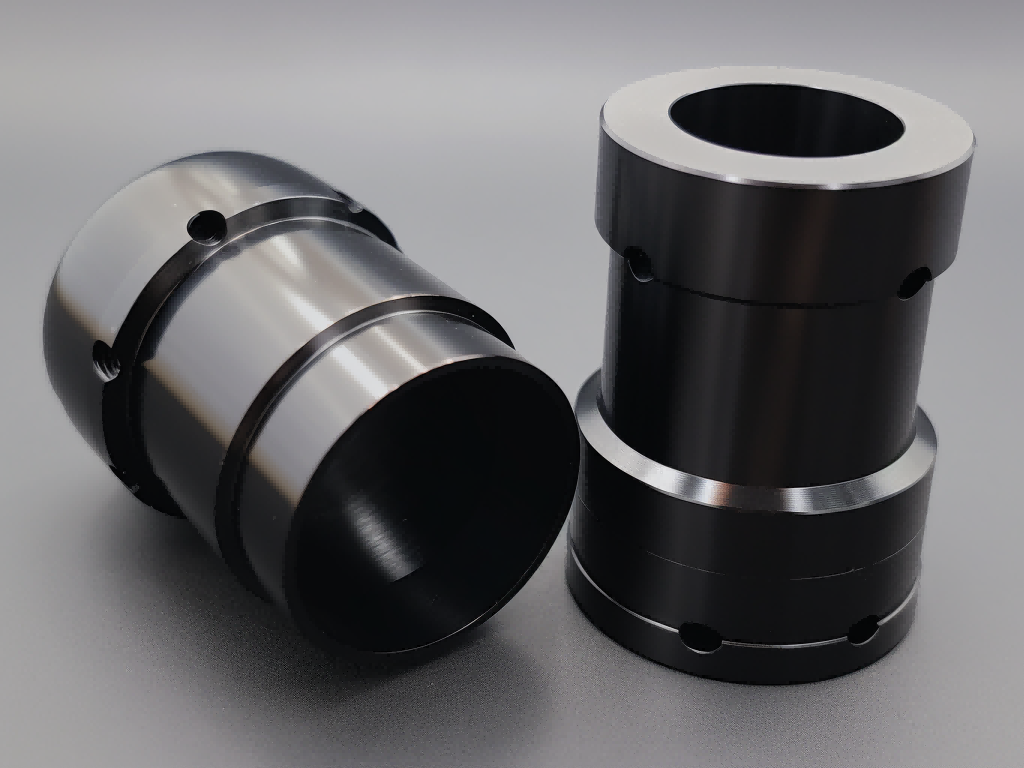

Our plasma cutting process delivers precision and versatility for producing custom metal parts. Explore high-quality, tailored components for a wide range of industrial applications.

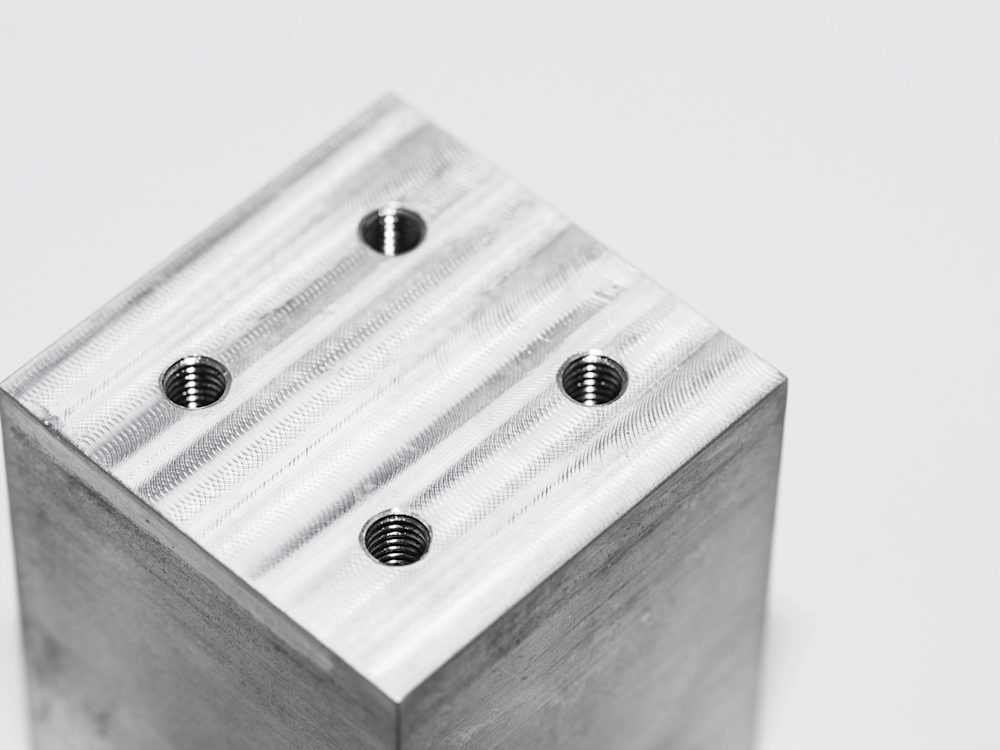

Neway Plasma Cutting Service Capabilities

Get Precision and Quality with Our Custom Plasma Cutting Services! We are a leading manufacturer of custom plasma-cut parts. With state-of-the-art equipment and experienced technicians, we deliver precise and accurate cuts for a wide range of materials. Trust us for all your plasma cutting needs!

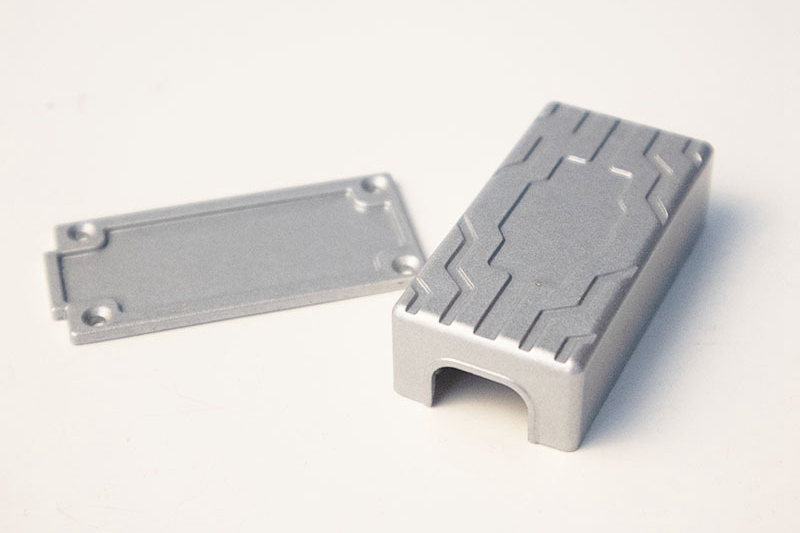

Custom Parts Surface Finishing Available

Our Surface Treatment Service offers specialized finishes for custom parts, enhancing durability, aesthetics, and performance. We provide a range of processes, including Electroplating, Anodizing, Powder Coating, and Thermal Barrier Coatings, tailored to improve corrosion resistance, wear properties, and visual appeal of metal and plastic components across industries.

learn more

As Machined

learn more

Painting

learn more

PVD

learn more

Sandblasting

learn more

Electroplating

learn more

Polishing

learn more

Anodizing

learn more

Powder Coating

learn more

Electropolishing

learn more

IMD

learn more

Brushed Finishes

learn more

Black Oxide

learn more

Heat Treatment

learn more

Tumbling

learn more

Alodine

learn more

Chrome Plating

learn more

Phosphating

learn more

Nitriding

learn more

Galvanizing

learn more

Lacquer Coating

learn more

Teflon Coating

learn more

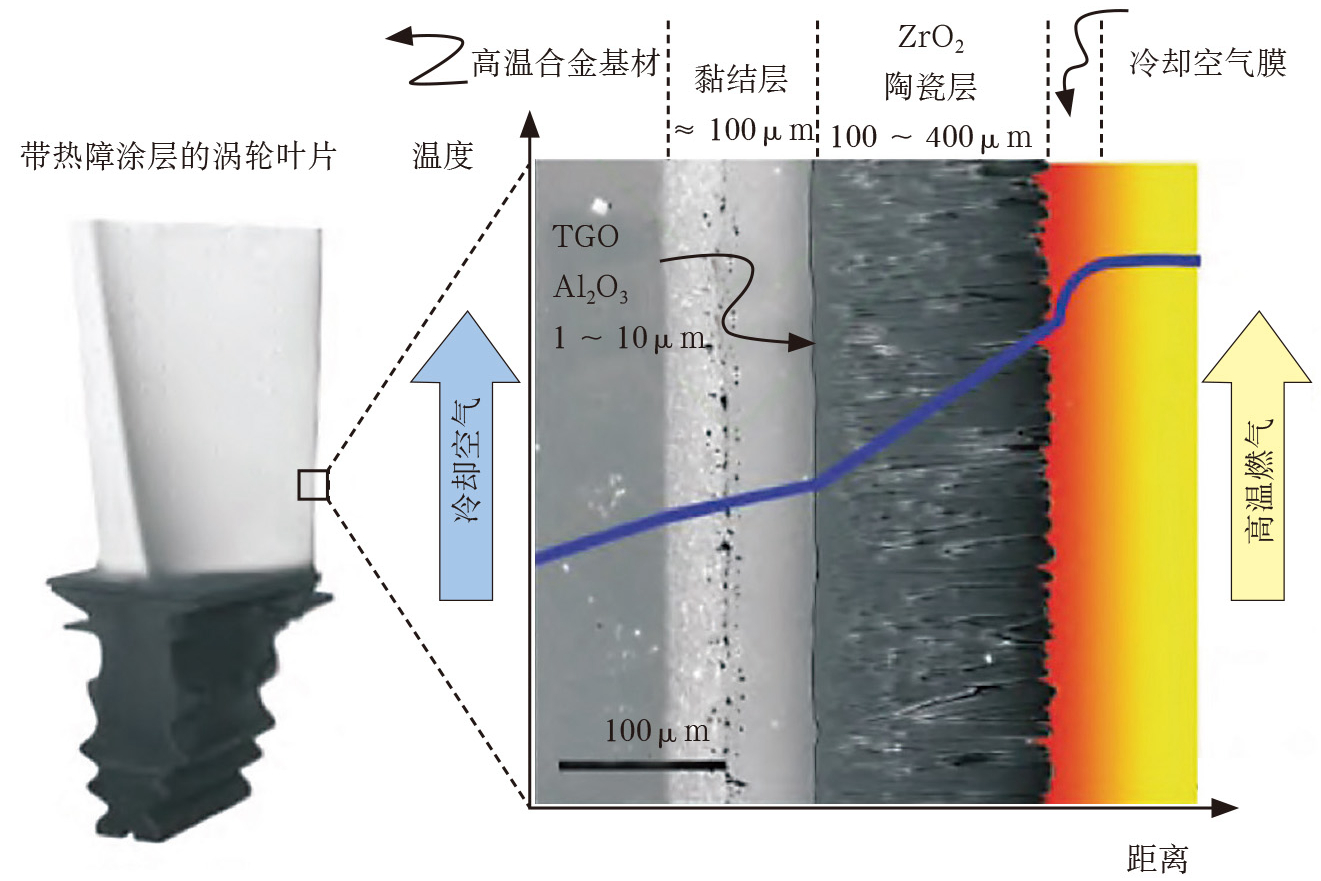

Thermal Coatings

learn more

Thermal Barrier Coatings

learn more

Passivation

Let's Start A New Project Today

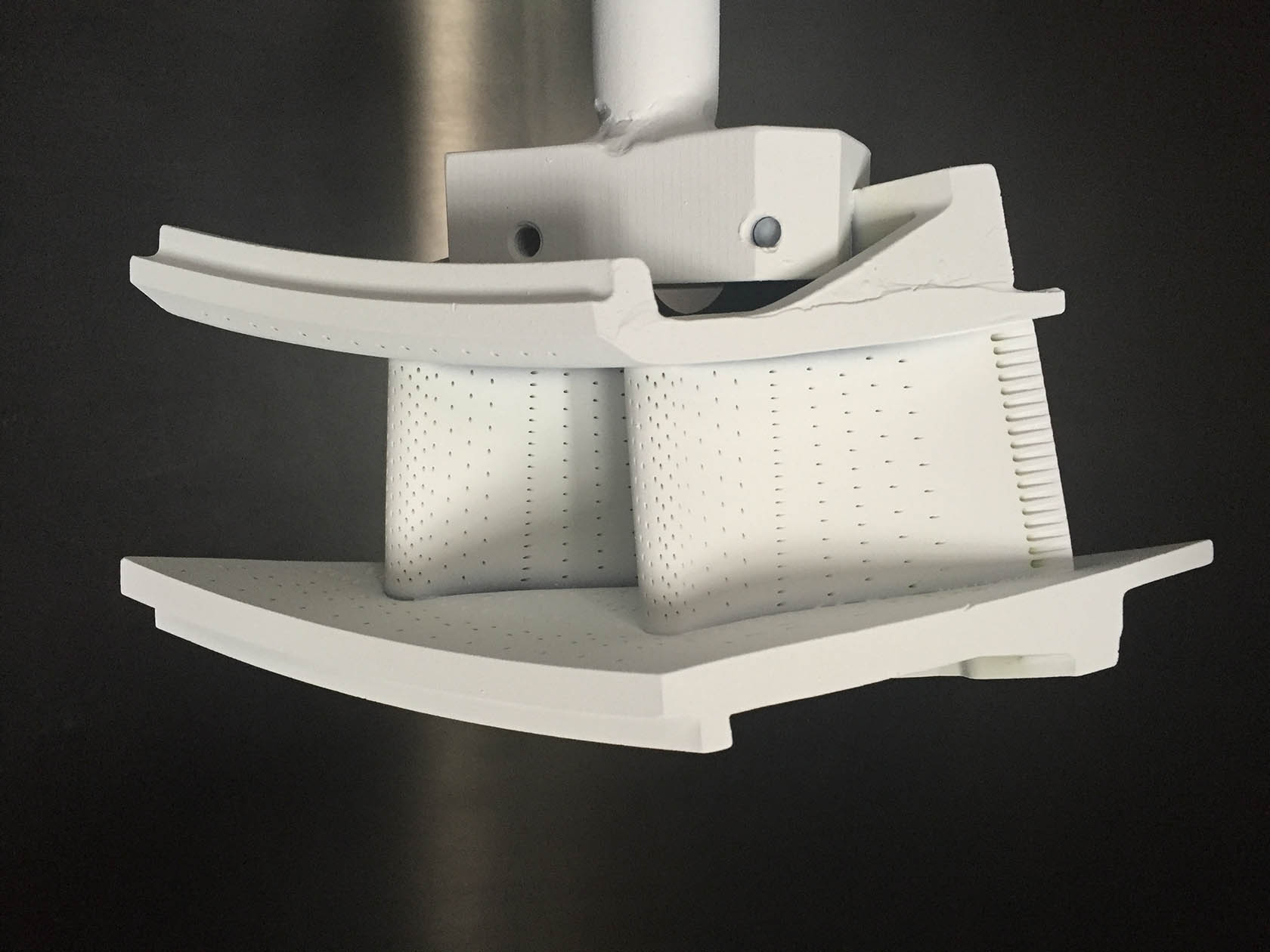

Custom Plasma Cutting Parts Design Guideline

These guidelines provide industry standard values for custom plasma cutting parts to ensure precise cutting, reduced thermal distortion, and optimal structural integrity, ultimately improving efficiency and quality while lowering production costs.

Frequently Asked Questions

Explore Related Resources

Solutions

Copyright © 2025 Neway Precision Works Ltd.All Rights Reserved.