Custom Overmolding Process

Overmolding is a two-step process where a plastic or rubber layer is molded over a previously manufactured plastic part, enhancing functionality, protecting the substrate, or providing better comfort.

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

Advantages of Over Molding Service

Over Molding Service enhances product durability, functionality, and aesthetics while reducing manufacturing costs. It combines materials to create composite parts with improved shock resistance, appealing finishes, and integral features like soft grips, contributing to streamlined production and heightened product performance.

Custom Overmolding Parts Applications

Our custom overmolding process delivers enhanced functionality and ergonomic features. Explore our wide range of overmolded components designed to improve product aesthetics and performance across various industries.

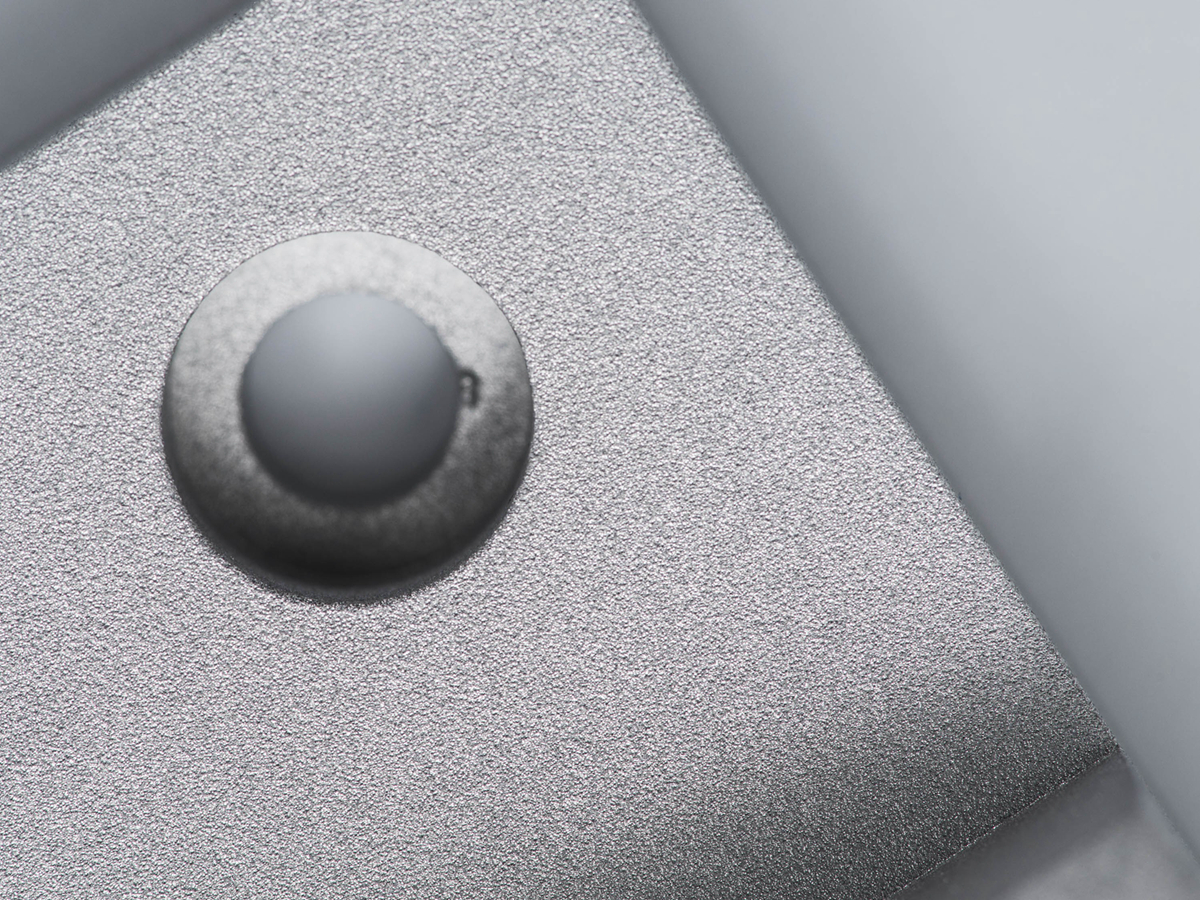

Custom Parts Surface Finishing Available

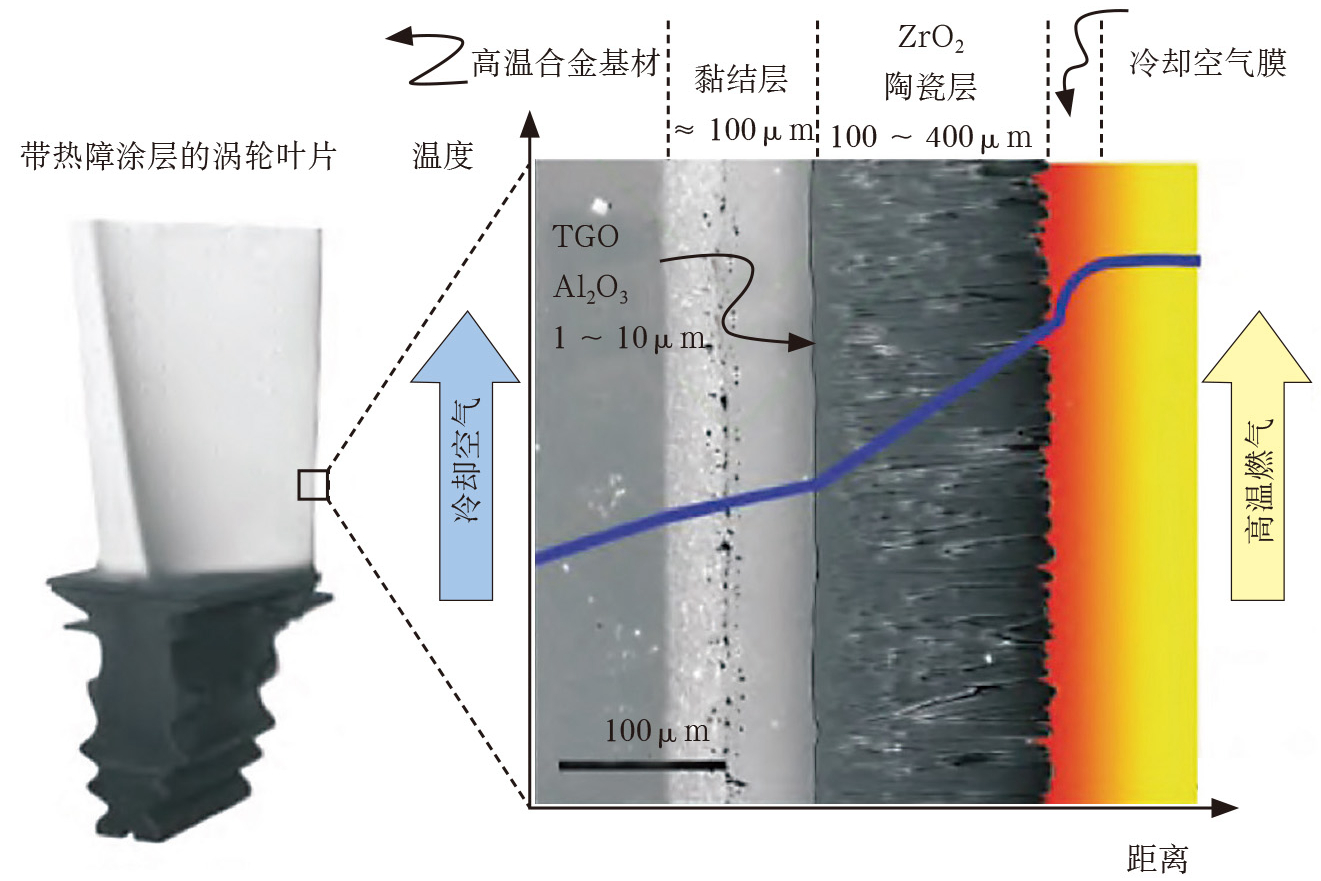

Our Surface Treatment Service offers specialized finishes for custom parts, enhancing durability, aesthetics, and performance. We provide a range of processes, including Electroplating, Anodizing, Powder Coating, and Thermal Barrier Coatings, tailored to improve corrosion resistance, wear properties, and visual appeal of metal and plastic components across industries.

learn more

As Machined

learn more

Painting

learn more

PVD

learn more

Sandblasting

learn more

Electroplating

learn more

Polishing

learn more

Anodizing

learn more

Powder Coating

learn more

Electropolishing

learn more

IMD

learn more

Brushed Finishes

learn more

Black Oxide

learn more

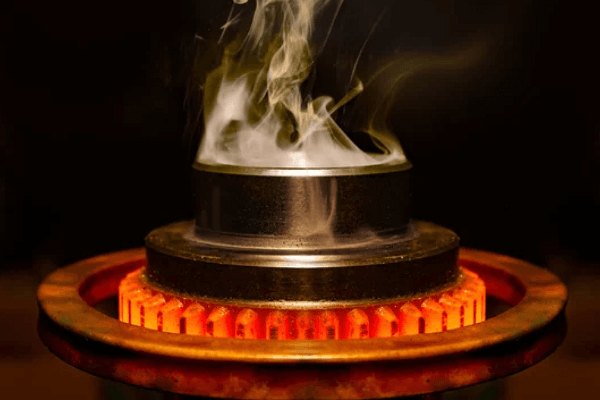

Heat Treatment

learn more

Tumbling

learn more

Alodine

learn more

Chrome Plating

learn more

Phosphating

learn more

Nitriding

learn more

Galvanizing

learn more

Lacquer Coating

learn more

Teflon Coating

learn more

Thermal Coatings

learn more

Thermal Barrier Coatings

learn more

Passivation

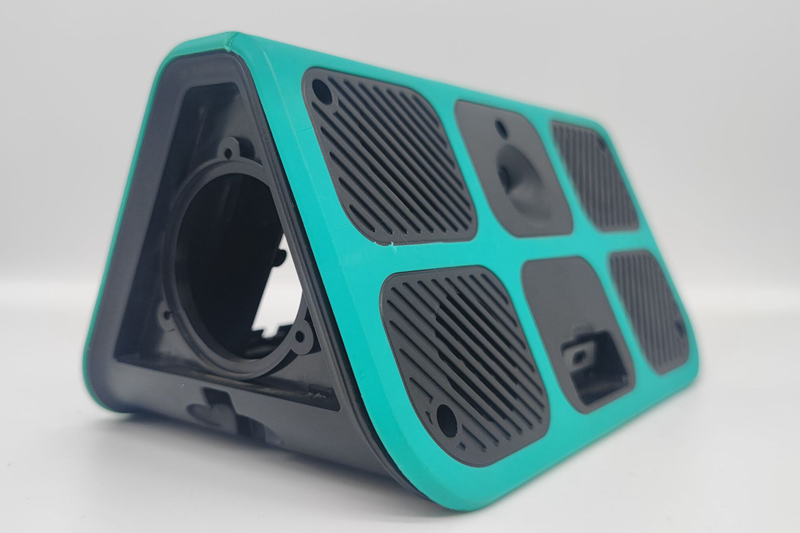

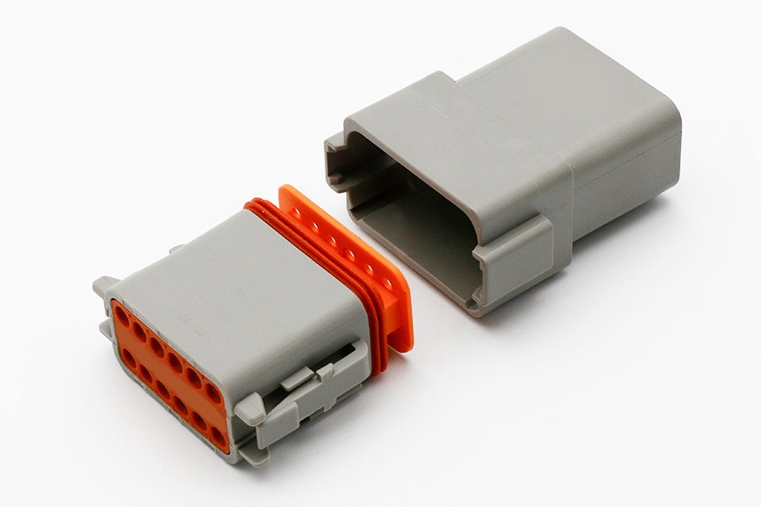

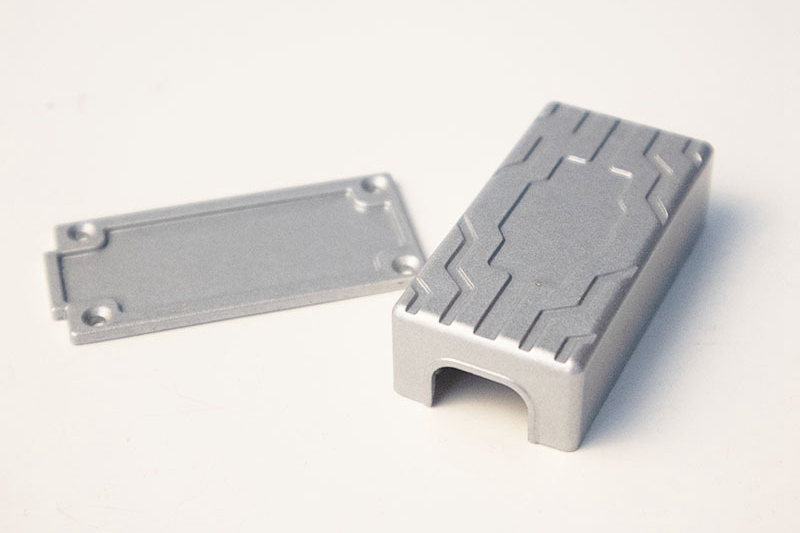

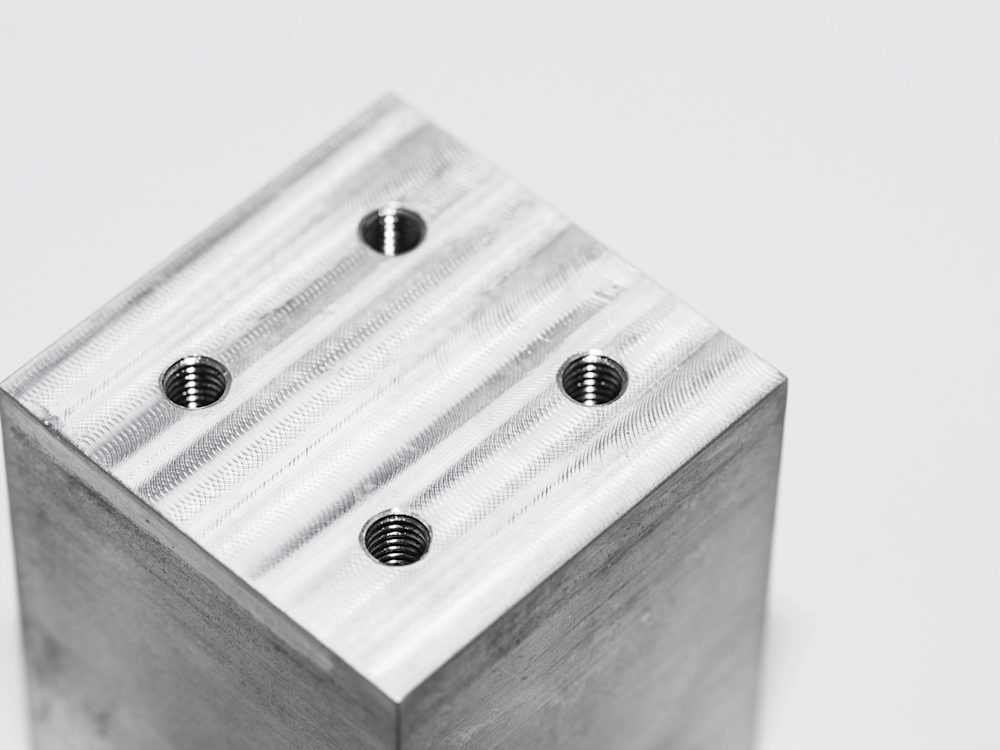

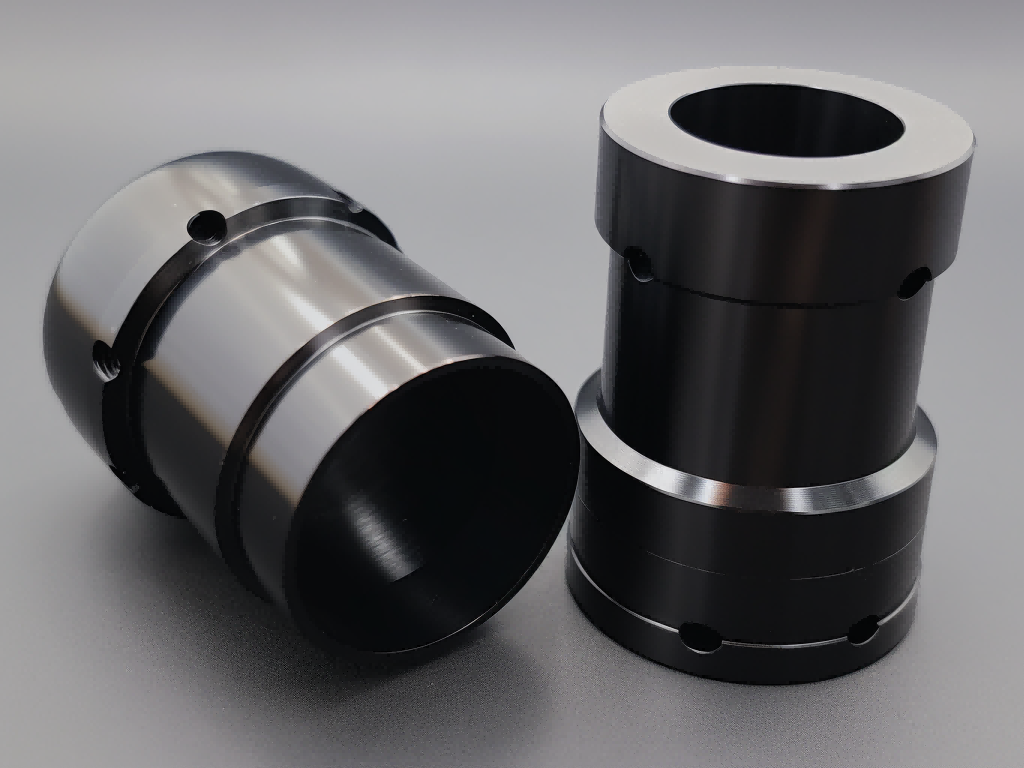

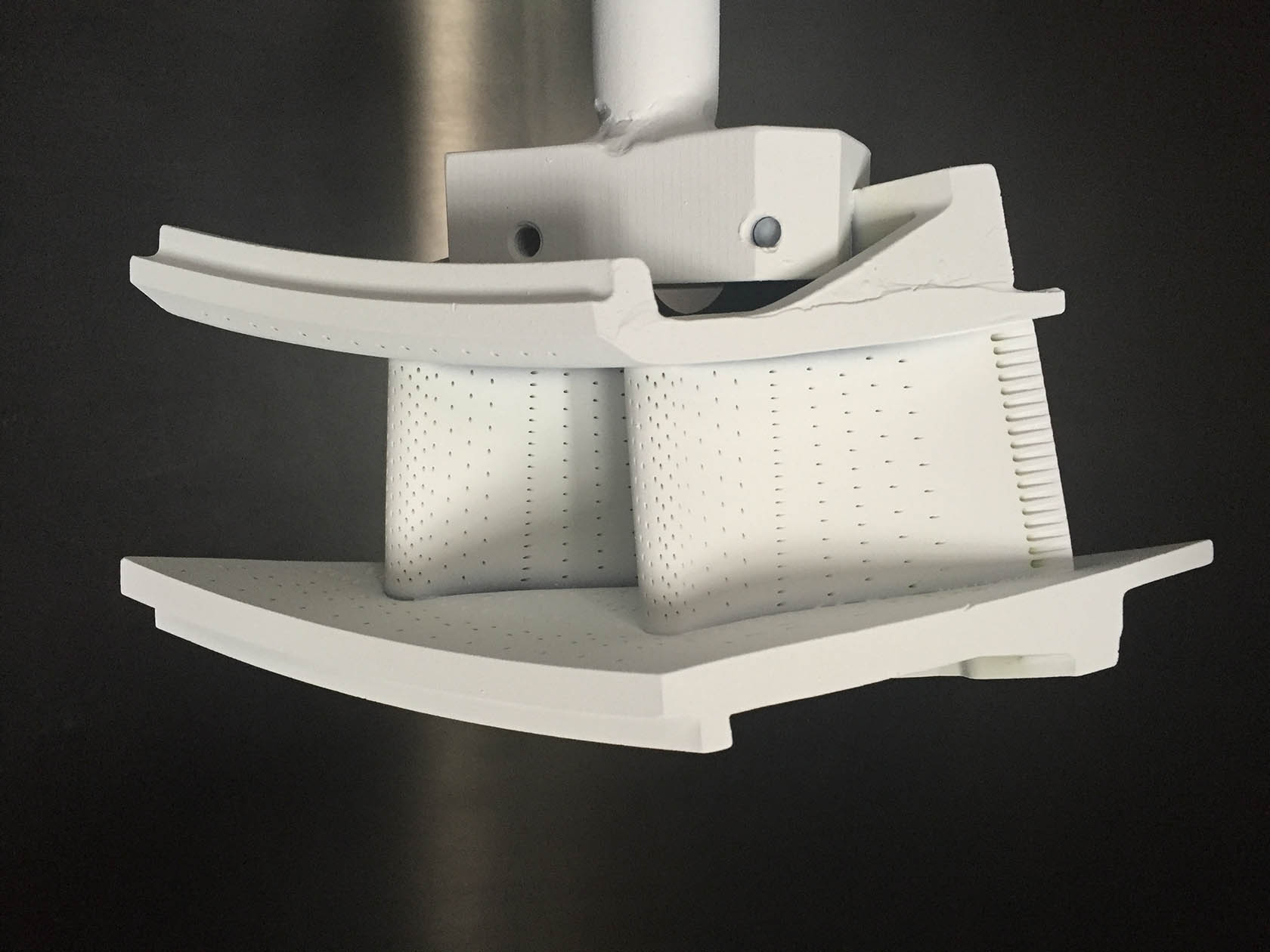

Custom Overmolding Parts Gallery

At our custom overmolding parts gallery, we understand that every project is unique. That's why we work closely with our customers to ensure that their custom parts are designed to meet their exact specifications. With our attention to detail and commitment to quality, you can trust that your custom parts will exceed your expectations.

Let's Start A New Project Today

Custom Overmolding Parts Design Suggestion

Understand the design limits for custom overmolding parts. These guidelines help optimize dimensions, tolerances, overmold thickness, substrate bonding, and production volumes to achieve cost-effective, high-quality overmolded components.

Frequently Asked Questions

Explore Related Resources

Solutions

Copyright © 2025 Neway Precision Works Ltd.All Rights Reserved.