Telecommunication Infrastructure: The Role of CNC Machined Parts in High-Speed Connectivity

Introduction

CNC machining plays a pivotal role in telecommunication infrastructure, enabling the production of precision-engineered parts essential for high-speed connectivity. As global demand for faster and more reliable communication networks increases, CNC machining provides the accuracy and consistency needed to support advanced telecom solutions.

Utilizing cutting-edge CNC machining manufacturing, telecommunication providers can produce components with tight tolerances and excellent material properties. CNC machining enhances network reliability, signal integrity, and equipment longevity, crucial for today's rapidly evolving digital landscape.

CNC Machining Steps

Component Design & Prototyping: Precise CAD/CAM modeling tailored to telecom hardware requirements.

Material Selection: Choosing optimal materials for electrical conductivity, durability, and thermal management.

Precision Manufacturing: Fabricating intricate telecommunication components through CNC machining.

Quality Assurance: Rigorous testing ensures components meet telecom industry standards.

Materials: Material Solutions for Telecommunication Infrastructure

Selecting appropriate materials significantly impacts telecom system reliability, performance, and durability. Typical CNC machined telecom materials include:

Material | Properties | Advantages | Applications |

|---|---|---|---|

Tensile Strength: 310-570 MPa Yield Strength: 280-500 MPa Excellent thermal conductivity | Lightweight, corrosion-resistant, effective thermal management | Antenna housings, RF component enclosures, heat sinks | |

Tensile Strength: 200-350 MPa Electrical Conductivity: 100% IACS Density: 8.96 g/cm³ | High electrical and thermal conductivity, easy machinability | Connectors, waveguides, grounding bars | |

Tensile Strength: 300-550 MPa Excellent electrical conductivity and corrosion resistance | Reliable electrical performance, machinability, durability | Coaxial connectors, RF fittings, telecom interfaces | |

Tensile Strength: 500-1,500 MPa Corrosion resistance: Excellent Durability in harsh environments | Strong, resistant to corrosion, suitable for outdoor applications | Cell tower brackets, base station components, equipment mounts |

Surface Treatment: Enhancing Telecommunication Component Durability

Anodizing

Functions: Anodizing enhances corrosion and wear resistance, creating protective oxide layers on aluminum.

Key Features: Hardness up to 400 HV, electrically insulating, improved surface durability.

Applications and Scenarios: Outdoor antenna casings, satellite components, telecom enclosures.

Electropolishing

Functions: Electropolishing improves electrical conductivity, enhances surface smoothness, and reduces corrosion risk.

Key Features: Surface roughness down to 0.1 µm, excellent corrosion resistance.

Applications and Scenarios: RF connectors, waveguides, precision telecom fittings.

Powder Coating

Functions: Powder Coating provides durable environmental protection and aesthetic finishes.

Key Features: Coating thickness typically 50-120 µm, resistant to UV exposure and corrosion.

Applications and Scenarios: Equipment cabinets, antenna mounts, outdoor telecom equipment.

Passivation

Functions: Passivation chemically enhances the corrosion resistance of stainless steel parts.

Key Features: Creates protective oxide layer and improves long-term durability.

Applications and Scenarios: Cell tower hardware, cable management systems, telecom connectors.

CNC Machining Process Comparison

Distinct CNC machining processes offer unique advantages tailored for telecommunication component manufacturing:

Process | Key Features | Application Scenarios |

|---|---|---|

Precision: ±0.0025 mm Capable of complex geometries | Antenna components, RF enclosures, complex brackets | |

Precision: ±0.0025 mm Efficient for cylindrical components | Connectors, RF fittings, waveguide couplings | |

Precision: ±0.0025 mm hole accuracy High-volume drilling capability | Base station chassis, heat sink mounting holes, telecom racks | |

Surface finish: up to 0.1 µm High accuracy and surface quality | Precision RF components, connector surfaces, optical device parts | |

Precision: ±0.0025 mm for complex components Flexible production capabilities | Complex antenna designs, integrated cooling structures, advanced telecom equipment |

Considerations in Production

Signal Integrity: Optimal material selection and precision machining to ensure minimal signal loss and interference.

Environmental Resistance: Surface treatments that withstand harsh outdoor environments, corrosion, and temperature extremes.

Thermal Management: Effective material choices and design considerations for efficient heat dissipation.

Precision Requirements: Maintaining tight tolerances through rigorous inspection protocols for consistent performance.

Industry and Applications

CNC machining significantly impacts multiple areas within the telecommunications sector:

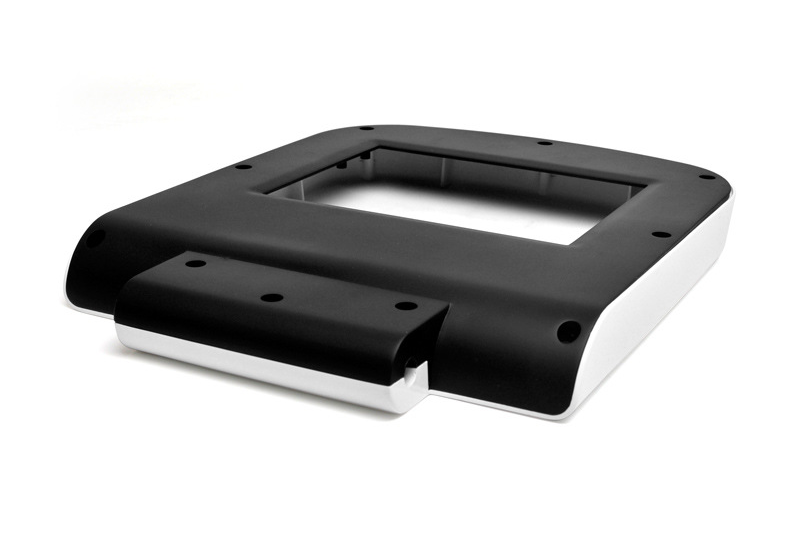

Industrial Equipment: Telecommunication hardware racks, precision enclosures, cooling systems.

Robotics & Automation: Automated telecom equipment handling, robotic cable management systems.

Consumer Products: High-speed routers, modems, satellite dishes.

Automotive Electronics: Vehicle telematics systems, antenna mounts, connectivity modules.

Power Generation: Backup power systems and battery enclosures for telecom infrastructure.

FAQs

Why is CNC machining essential in telecommunication infrastructure manufacturing?

Which materials are most commonly CNC machined for telecom components?

How does CNC machining contribute to improved telecom connectivity?

What surface treatments are crucial for telecom components exposed to harsh conditions?

How do different CNC machining processes benefit telecommunication equipment production?