Strengthening Signal Integrity: The Role of Metal Injection Molding in Telecommunication Equipment

Introduction

The telecommunications industry is evolving rapidly, driven by increasing global connectivity demands and the need for clearer, faster, and more reliable data transmission. Optimal signal integrity is crucial, as minor disruptions can significantly impact network performance, resulting in data loss, slower communication speeds, or reduced reliability.

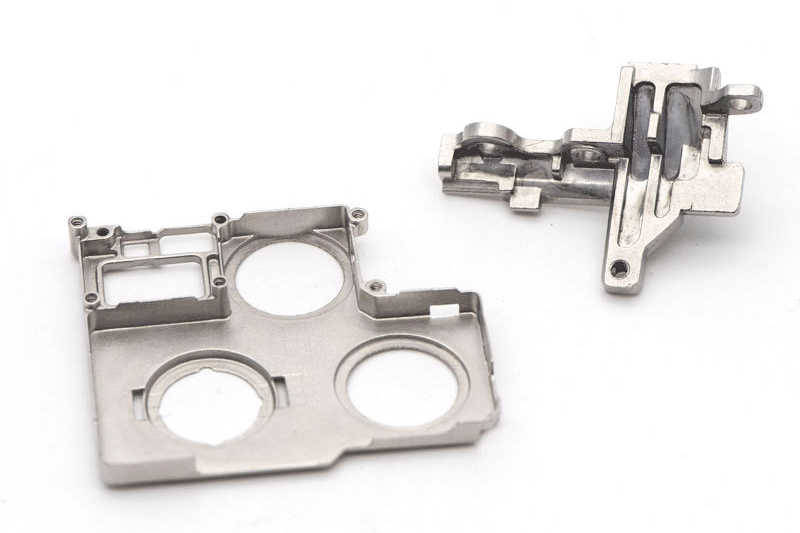

Metal Injection Molding (MIM) plays a vital role in addressing these challenges. By producing highly precise, complex metal components with exceptional electromagnetic properties, MIM ensures telecommunication equipment achieves consistent reliability, improved performance, and superior signal integrity, essential for modern high-speed communication networks.

MIM Manufacturing Process for Telecom Equipment

Metal Injection Molding is a specialized multi-step manufacturing technique, particularly suitable for producing precision telecommunication components requiring complex geometries and excellent electromagnetic properties:

Feedstock Preparation

The process begins with creating a uniform feedstock—finely powdered metals precisely blended with polymer binders. This meticulous preparation ensures consistent flow characteristics, which are essential for molding precision telecom components, such as intricate connectors, EMI shielding, and antenna mounts.

High-Precision Injection Molding

Next, the homogeneous feedstock is heated and injected into meticulously engineered molds under controlled conditions. Injection molding enables precise replication of complex geometries and detailed internal structures, essential for components like high-frequency connectors and antenna enclosures, where dimensional accuracy directly impacts signal quality and reliability.

Controlled Debinding Process

Post-injection molding, components undergo debonding—a controlled thermal or chemical process removing polymer binders without compromising structural integrity. This step ensures dimensional accuracy and prevents distortion, crucial for telecom components like connectors and RF shields, where even slight dimensional variations affect performance significantly.

Sintering for Enhanced Mechanical and Electromagnetic Properties

Finally, components undergo sintering—heating below the metal’s melting point—to consolidate metal particles into a dense, robust structure. Sintering enhances mechanical strength, density, and electromagnetic properties, critical for telecom components that must reliably perform in high-demand environments with minimal signal degradation.

Advantages of MIM in Telecommunications Manufacturing

Metal Injection Molding provides several unique advantages tailored specifically to telecommunications manufacturing:

Complex Component Manufacturing: MIM allows intricate internal structures and external geometries not achievable through traditional manufacturing methods, critical for EMI shielding, high-frequency connectors, and antenna components.

High Dimensional Precision and Repeatability: Achieves consistent dimensional accuracy across large production volumes, crucial for telecom equipment needing precise fitting and reliable performance.

Superior Signal Integrity: Delivers smoother surfaces and precise geometries, significantly reducing signal attenuation and interference, essential for high-frequency telecom applications.

Cost-Effective High-Volume Production: Enables scalable manufacturing at lower costs by minimizing waste, ensuring economical yet high-quality production ideal for mass-produced telecom equipment.

Typical Materials Used in Telecommunications Equipment

Proper material selection directly impacts telecom components' performance, reliability, and signal integrity. Essential materials used in MIM telecom manufacturing include:

Stainless Steel Alloys

17-4 PH Stainless Steel: Provides high tensile strength, durability, and corrosion resistance, suitable for RF connectors, antenna brackets, and robust structural telecom parts.

MIM 316L Stainless Steel: Offers exceptional corrosion resistance ideal for telecom components deployed in harsh outdoor environments, such as antenna mounts and connector housings.

Copper Alloys

Copper-based Alloys: Renowned for superior electrical conductivity and effective thermal management, crucial for connectors, terminals, grounding systems, and antenna interfaces demanding efficient signal transmission and heat dissipation.

Magnetic Alloys

Fe-50Ni Alloy: Exhibits high magnetic permeability, making it invaluable for EMI shielding applications. Effective shielding minimizes interference, enhancing signal clarity and improving telecom equipment reliability.

Superalloys

Inconel 625: Known for outstanding thermal and oxidation resistance, suitable for high-performance telecom environments like satellite communication equipment, base station components, and other applications exposed to extreme thermal and environmental conditions.

Surface Treatments Enhancing Telecom Component Performance

Advanced surface treatments significantly enhance the performance, reliability, and durability of MIM-produced telecom components:

Gold and Silver Electroplating

Gold and silver electroplating: Provides superior electrical conductivity and corrosion resistance, critical for minimizing signal loss and maintaining consistent high-frequency transmission in connectors and terminals.

Passivation

Passivation: Removes surface contaminants, creating a protective oxide layer, significantly enhancing corrosion resistance. It is essential for telecom components frequently exposed to harsh outdoor environments.

Electropolishing

Electropolishing: Delivers ultra-smooth, defect-free surfaces, essential for high-frequency telecom components. Smooth surfaces minimize signal reflection and attenuation, optimizing clarity and data transmission efficiency.

Black Oxide Coating

Black oxide coating: Offers corrosion resistance and aesthetic appeal, ideal for visible telecom equipment such as external enclosures, base station housings, and mounting brackets, ensuring reliability and durability.

PVD Coatings (Physical Vapor Deposition)

PVD coatings: Enhances wear resistance, durability, and electrical conductivity. It particularly benefits connectors, switches, and terminals in telecom applications requiring stable, long-term operation.

Production Considerations for Telecommunications Components

Achieving optimal outcomes using MIM in telecom manufacturing requires careful attention to critical factors:

Optimal Material Selection: Choosing materials specifically tailored to telecom equipment's electromagnetic, mechanical, and thermal demands to ensure long-term performance.

Surface Treatment Integration: Precisely pairing surface treatments with component functions to maximize performance, minimize signal attenuation, and enhance component lifespan.

Rigorous Quality Assurance: Employing stringent testing protocols and production control systems ensures compliance with industry standards, consistently producing high-quality components.

Cost and Quality Balance: Balancing efficient production with maintaining high quality and precision, ensuring competitiveness in the demanding telecom marketplace.

Key Applications of MIM in Telecommunications Equipment

MIM significantly impacts telecom equipment across essential applications:

RF Connectors and Antenna Components

EMI Shielding and RF Enclosures

High-Frequency Connectors and Terminals

Base Station Structural Components

Satellite Communication System Parts

Conclusion

Metal Injection Molding is instrumental in strengthening signal integrity and reliability in telecommunications. By combining advanced manufacturing processes, specialized materials, and sophisticated surface treatments, MIM empowers manufacturers to produce innovative telecom equipment capable of supporting future global connectivity demands. As the telecom industry progresses toward higher speeds and enhanced clarity, adopting MIM technology remains essential for achieving superior performance, reliability, and competitive advantage.

FAQs

How does Metal Injection Molding enhance telecommunications equipment reliability?

What are the key MIM materials used in telecom applications?

Why are specific surface treatments essential for telecommunications components?

Which telecom equipment components are most improved by MIM technology?

How does MIM support cost efficiency in mass-produced telecom equipment?