Plastic Aerospace Accessories MC Nylon CNC Machining Gear Rack

Technology | CNC machining |

Material | MC nylon |

Surface finish | As machined |

Tolerance | H4 level tolerance, vertical tolerance 0.005mm |

Product | Gears and Rack |

Industry | Aerospace products |

The result | Small batches of high-quality, on-demand custom manufacturing |

Why Neway Precision? | Needing to balance quality, surface finish, and price |

In the aerospace industry, where every micron counts and every detail matters, precision isn't just a requirement—it's the standard. Aerospace accessories, whether gears, racks, or enclosures, demand the highest levels of accuracy to ensure the equipment's safety, functionality, and longevity. At Neway, we understand the critical nature of these components and are dedicated to producing them with the utmost precision and quality.

With advanced technologies, meeting these stringent standards has become more achievable. CNC machining stands at the forefront of this revolution, offering unparalleled accuracy and efficiency in manufacturing complex parts. In this blog post, we will explore how Neway utilizes state-of-the-art CNC machining technology to craft durable, precise, and cost-effective plastic aerospace accessories, mainly focusing on our use of MC nylon to produce gears and racks. Our commitment to quality ensures that each part not only meets but exceeds industry expectations, providing our clients with reliable and superior products tailored to the demanding needs of the aerospace sector.

Understanding CNC Machining

CNC (Computer Numerical Control) machining is a cornerstone technology in modern manufacturing, especially in industries where precision and repeatability are paramount. By automating the control of machine tools via a computer, CNC machining eliminates human error. It increases production efficiency, making it ideal for the intricate demands of aerospace components.

The Basics of CNC Machining

CNC machining involves pre-programming the movements of machinery and the tools they control. This programming is executed through precise instructions coded into a computer, allowing complex shapes to be cut and formed accurately. The process starts with a digital blueprint, then translated into numerical codes that guide the machine's movements.

Advantages for Aerospace Applications

For aerospace accessories like gears and racks, CNC machining provides several distinct advantages:

Precision: CNC machines can achieve incredibly tight tolerances, which is crucial for the aerospace industry, where even the most minor discrepancy can lead to failure.

Complexity: With CNC machining, complex designs that are difficult or impossible to achieve with manual machining can be realized. This capability allows for the production of intricate parts essential for modern aerospace systems.

Repeatability: Once a design is programmed, CNC machines can produce hundreds or thousands of virtually identical parts, ensuring consistency across batches, which is vital for aerospace components.

Material Versatility: CNC machines can handle a variety of materials — from metals to plastics like MC nylon — providing flexibility in choosing the suitable material for specific aerospace applications.

Enhanced Capabilities at Neway

At Neway, our CNC machining capabilities are equipped with the latest technology, ensuring that every part we produce meets stringent industry standards. Our machines can operate on multiple axes, which allows for the crafting of three-dimensional cutting tasks with high precision. This technological edge translates into better performance, reliability, and safety for aerospace components, emphasizing our commitment to pushing the boundaries of what's possible in aerospace manufacturing.

Material Selection - MC Nylon

In producing aerospace accessories, choosing a suitable material is as critical as the manufacturing process. MC nylon, a polyamide known for its robust properties and cost-effectiveness, is an exemplary choice for many aerospace applications. This section delves into why MC nylon is favored for creating components like gears and racks, which are integral to aerospace mechanisms.

Properties of MC Nylon

MC nylon, or Monomer Cast nylon, offers several attributes that make it particularly suited for aerospace needs:

Strength and Durability: MC nylon is renowned for its high tensile and compressive strength, which is crucial for parts subjected to high mechanical loads.

Lightweight: It offers a significant weight advantage, crucial in aerospace applications where every gram counts. This weight reduction can lead to better fuel efficiency and increased payload capacity.

Wear Resistance: MC nylon possesses excellent wear resistance, essential for components like gears and racks that experience constant friction. It must maintain its integrity over many cycles of use.

Corrosion Resistance: Unlike metal parts, MC nylon is resistant to corrosion and degradation from chemicals, making it ideal for use in environments exposed to harsh conditions.

MC Nylon vs. Other Materials

While metals such as aluminum or steel have traditionally been used in aerospace, MC nylon provides a compelling alternative due to its unique combination of lightness and strength. Compared to other polymers, MC nylon typically offers superior structural and thermal properties, which benefit applications demanding long-term reliability and performance.

Cost-Effectiveness

One of the most significant advantages of MC nylon is its cost-effectiveness. When considering the entire lifecycle of aerospace accessories, using MC nylon can reduce costs in terms of raw materials and lower manufacturing expenses. Its machinability allows for quicker production times and less wear on tooling compared to more complex materials like metals.

Why Neway Chooses MC Nylon

At Neway, our decision to utilize MC nylon for specific aerospace accessories stems from our commitment to delivering products that meet high quality and durability standards while managing production costs. Our expertise in CNC machining MC nylon allows us to exploit its properties fully, producing components that are not only cost-efficient but also perform exceptionally well under the demanding conditions of aerospace applications.

Achieving Precision with High Tolerances

Precision is paramount in aerospace engineering, where even the slightest deviation can significantly impact performance and safety. At Neway, we achieve exceptional precision in our aerospace accessories through stringent tolerance controls, especially when working with MC nylon to manufacture gears and racks.

Importance of Tolerance in Aerospace Products

Tolerance refers to the permissible limits of variation in a physical dimension. In aerospace, where systems must operate reliably under extreme conditions, maintaining high-level tolerance ensures compatibility and functionality across various parts. The specified tolerances help achieve the components' desired fit, performance, and longevity.

H4 Level Tolerance and Its Significance

Neway adheres to H4 level tolerance, one of the highest precision standards in machining, allowing for a vertical tolerance of just 0.005mm. This degree of precision is critical for several reasons:

Enhanced Fit and Assembly: High precision tolerances facilitate better assembly of parts, reducing the need for additional adjustments during manufacturing and assembly processes.

Improved Functional Performance: Precise components function more reliably, with lower risks of failure due to misalignment or improper fitting.

Increased Durability: Uniformity in manufacturing reduces wear and tear, as parts fit and work together as intended, prolonging the lifecycle of the aerospace products.

Achieving Precision with CNC Machining

Neway leverages advanced CNC machining technologies to reach and maintain H4 level tolerances consistently. These machines are calibrated to operate extremely accurately, ensuring that every cut and engraving on MC nylon or other materials meets the specifications. The ability of CNC machines to replicate designs with high fidelity means that each part remains true to the digital blueprints, regardless of the production volume.

Continuous Quality Control

At Neway, achieving these tolerances is not just about having the right technology—it also involves rigorous quality control processes. Each part we produce undergoes thorough inspections using precision measuring instruments. This meticulous approach ensures that all manufactured items conform to the specifications and maintain the high standards expected in the aerospace industry.

The Impact on Product Reliability and Performance

By maintaining H4 level tolerance, Neway ensures that aerospace components like gears and racks meet and exceed the industry's rigorous demands. This commitment to precision boosts the reliability and performance of the products, giving our clients confidence in their operational capabilities and safety.

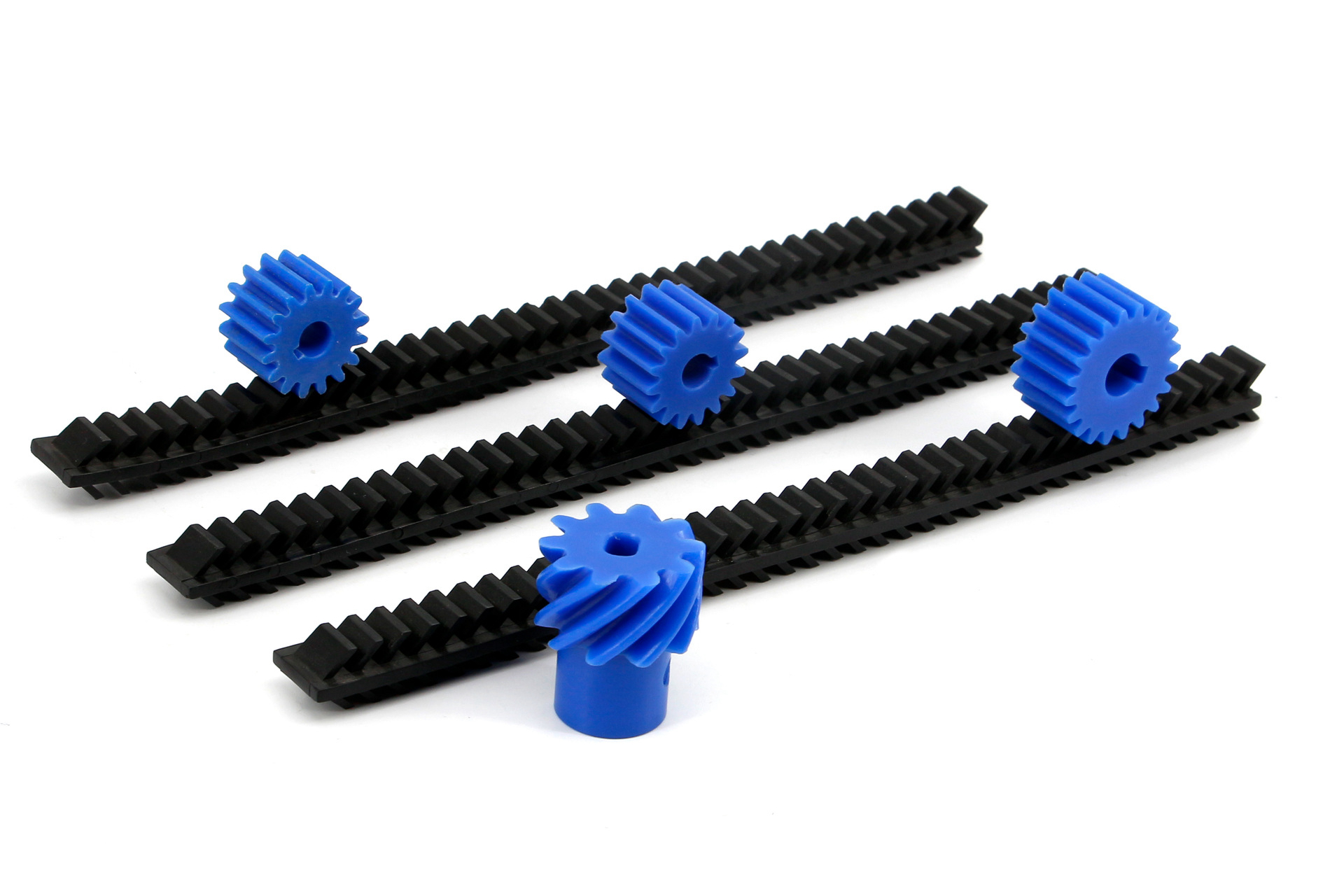

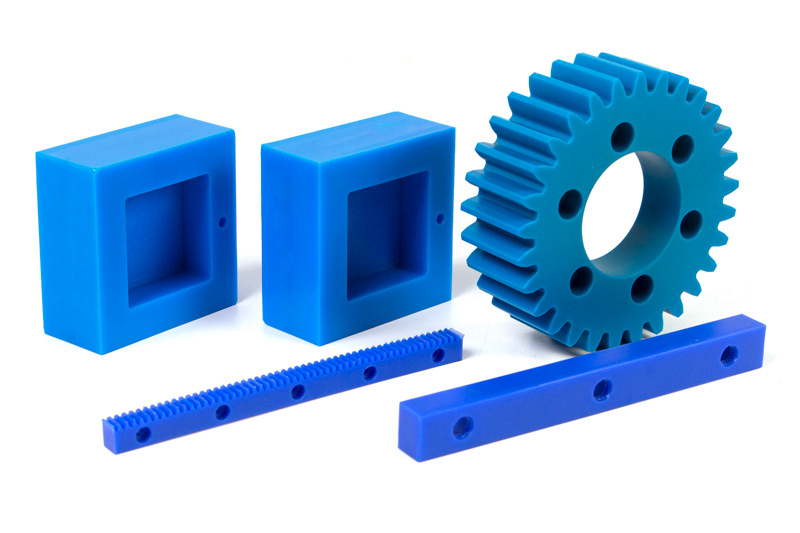

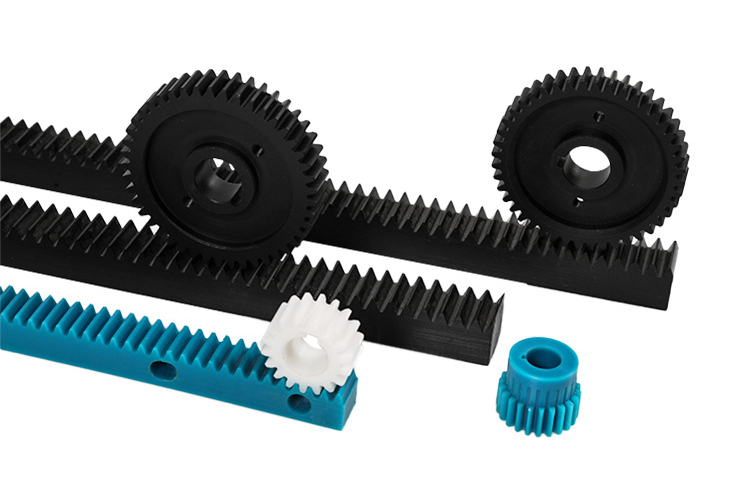

Product Focus - Gears and Rack

Every component plays a critical role in the intricate world of aerospace mechanisms. Gears and racks, often overlooked, are fundamental to the efficient functioning of many aerospace systems. At Neway, we specialize in the precision manufacturing of these essential parts using CNC machining and high-quality materials like MC nylon, ensuring they meet the stringent demands of the aerospace industry.

The Role of Gears and Racks in Aerospace Systems

Gears and racks are pivotal in translating rotational motion into linear motion and vice versa, which is essential in various aerospace applications. These components ensure smooth, precise movements, from the aircraft's control surfaces to the adjustment mechanisms in satellite dishes. They are integral to the reliability of the entire system.

Design and Manufacturing Challenges

The design and manufacturing of gears and racks come with their own set of challenges, particularly when they must meet aerospace standards:

Complexity of Design: Gears and racks in aerospace applications often feature complex geometries that require precise execution to function as intended.

Material Requirements: The materials must be strong, durable, lightweight, and resistant to environmental factors such as temperature fluctuations and chemical exposures.

Precision Engineering with CNC Machining

Neway uses CNC machining to achieve the high precision required for aerospace gears and racks. Our advanced CNC machines handle the intricate details of each gear and rack with exceptional accuracy, ensuring:

Perfect Meshing: Accurate gears translate to efficient power transmission and reduced mechanical wear.

Smooth Operation: Precision-cut racks contribute to the seamless operation of mechanisms, which is crucial for safety and functionality in aerospace environments.

Quality Assurance in Production

At Neway, quality assurance is embedded in every step of the production process. Each gear and rack is meticulously examined from the initial design phase to the final inspection to ensure it meets our high standards. It includes:

Dimensional Accuracy: Using state-of-the-art measuring tools to verify that each component adheres to the specified dimensions and tolerances.

Functional Testing: Rigorous testing of the gears and racks under simulated operational conditions to guarantee performance reliability.

Neway's Commitment to Excellence

Our commitment at Neway extends beyond manufacturing. We partner with aerospace engineers and designers to understand the specific requirements of their projects, ensuring that our gears and racks perfectly fit their applications. This collaborative approach helps refine product designs and optimize functionality, demonstrating our dedication to meeting and exceeding customer expectations.