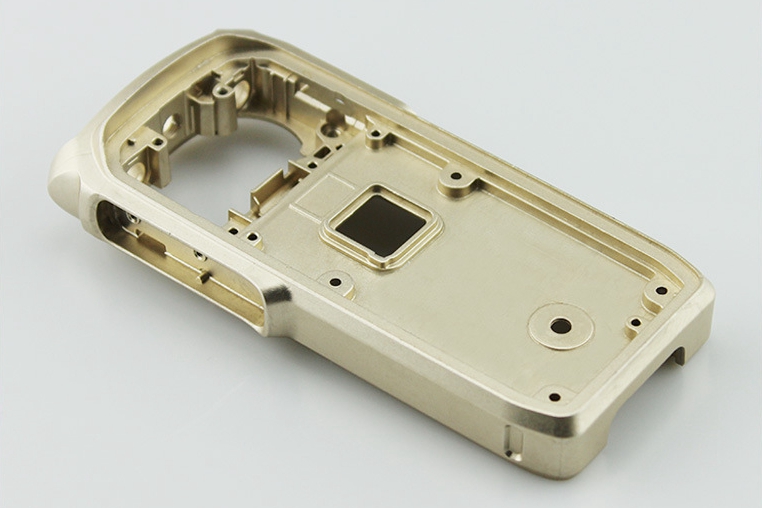

Manufacturing 383 Aluminum Alloy Mini Intercom Housing Using Die Casting Technology

In the fast-paced telecommunication industry, durable and precisely engineered components are paramount. One critical component is the mini intercom housing, which requires strength, precision, and high-quality finishing. This blog delves into the manufacturing process of mini intercom housings made from 383 Aluminum alloys, showcasing the technologies and techniques used to meet these demands.

383 Aluminum Alloy stands out due to its excellent corrosion resistance, good mechanical properties, and suitability for thin wall casting, making it an ideal material for intercom housings. This blog will explore the comprehensive manufacturing process, including aluminum die casting, CNC machining, threading, polishing, and Physical Vapor Deposition (PVD) finishing.

Through this detailed look, we aim to provide insights into the challenges and solutions involved in producing high-quality mini intercom housings, ensuring they meet the rigorous standards of the telecommunication industry.

Understanding 383 Aluminum Alloy

Properties of 383 Aluminum Alloy

383 Aluminum Alloy is a widely used material in the die-casting industry, known for its excellent balance of properties. Here are some key characteristics that make it suitable for mini intercom housings:

High Corrosion Resistance: 383 Aluminum Alloy exhibits strong resistance to corrosion, making it ideal for use in environments where the intercom housing may be exposed to moisture or other corrosive elements.

Good Mechanical Properties: This alloy offers strength and flexibility, essential for maintaining the structural integrity of thin-walled components.

Excellent Castability: The alloy's fluidity and low shrinkage make it particularly well-suited for die-casting processes, allowing for the production of complex shapes and fine details.

Suitability for Thin Wall Casting: One of the standout features of 383 Aluminum Alloy is its ability to be cast into thin-walled sections without compromising strength or durability, which is crucial for mini intercom housings.

Comparison with Other Aluminum Alloys

When selecting a material for die-casting mini intercom housings, it's essential to consider how 383 Aluminum Alloy stacks up against other commonly used aluminum alloys:

Versus 380 Aluminum Alloy: While 380 is similar in many respects, 383 Aluminum Alloy offers slightly better corrosion resistance and improved die-filling characteristics, making it preferable for thin-walled and intricate designs.

Versus 360 Aluminum Alloy: 360 provides excellent pressure tightness and is used for high-strength components. However, 383 is often preferred for its superior casting characteristics and ease of use in producing complex shapes.

Application in Mini Intercom Housing

Using 383 Aluminum Alloy in mini intercom housings leverages these properties to deliver a lightweight and robust product. The alloy's high corrosion resistance ensures long-term durability. At the same time, its excellent castability allows for creating houses with precise dimensions and intricate designs.

In telecommunication, where components are expected to perform reliably in various environmental conditions, 383 Aluminum Alloy offers a reliable solution. Its suitability for thin-wall casting makes it particularly advantageous for mini intercom housings, where compactness and efficiency are essential.

In summary, the 383 Aluminum Alloy combines corrosion resistance, mechanical strength, and castability and is well-suited for the telecommunication industry's demanding requirements for mini intercom housings.

Manufacturing Process Overview

Description of the Overall Manufacturing Process

Manufacturing mini intercom housings using 383 Aluminum Alloy involves intricate steps, each critical to ensuring the final product meets the highest quality and performance standards. The process integrates several advanced manufacturing technologies: aluminum die casting, CNC machining, threading, polishing, and Physical Vapor Deposition (PVD) finishing.

Aluminum Die Casting: This process begins with creating precise molds for the intercom housing. Molten 383 Aluminum Alloy is injected into these molds under high pressure, forming the basic shape of the housing with thin walls and intricate details.

CNC Machining: CNC machining achieves high-precision assembly surfaces and exact dimensions after casting. This step ensures that all housing components fit together seamlessly and function correctly.

Threading: The housings are then threaded, providing the necessary features for assembly. Accurate threading is crucial for ensuring the durability and functionality of the final product.

Polishing: To prepare the surface for finishing, the housings undergo polishing. This step smooths the surfaces, removing any imperfections that could affect the quality of the PVD coating.

PVD Finishing: Finally, PVD (Physical Vapor Deposition) coating is applied. This advanced finishing process enhances the housing's durability, appearance, and resistance to wear and corrosion.

Importance of Each Step in Achieving the Final Product Quality

Each stage in the manufacturing process plays a vital role in achieving the desired quality and performance of the mini intercom housing.

Die Casting: Ensures the structural integrity and dimensional accuracy of the housing. Proper mold design and casting techniques are essential for producing thin-walled components without defects.

CNC Machining: Provides the high precision needed for critical assembly surfaces. Accurate machining ensures that all parts fit perfectly, maintaining the intercom's functionality and reliability.

Threading: Adds necessary assembly features with high precision, ensuring robust and secure connections. Poor threading can lead to assembly issues and functional failures.

Polishing: Prepares the surface for PVD finishing by eliminating imperfections that could compromise the coating's adhesion and appearance. A smooth surface is crucial for achieving a high-quality finish.

PVD Finishing: Enhances the housing's surface properties, providing excellent wear resistance, hardness, and aesthetic appeal. This final step ensures that the housing performs well and looks professional and durable.

Integrated Approach for Optimal Results

Integrating these technologies in a seamless manufacturing workflow is critical to producing high-quality mini intercom housings. Each process stage complements the others, resulting in a final product that meets the rigorous demands of the telecommunication industry.

Synergy of Processes: The combination of die casting, CNC machining, threading, polishing, and PVD finishing ensures that each housing is functionally robust and aesthetically pleasing.

Quality Control: During manufacturing, stringent quality control measures are implemented to detect and correct deviations, ensuring consistent product quality and performance.

Die Casting Process

Detailed Explanation of the Die Casting Process for 383 Aluminum Alloy

Die casting is a manufacturing process that involves forcing molten metal under high pressure into a mold cavity. For 383 Aluminum Alloy, this process is particularly advantageous due to its excellent castability and ability to produce intricate and thin-walled components.

Mold Design Considerations for Thin Walls: The mold design is crucial when working with thin-walled components. To prevent weak points and ensure even cooling, the mold must account for uniform wall thickness for mini intercom housings. Advanced simulation software is often used to optimize mold design and predict potential issues before production begins.

Injection Process: Molten 383 Aluminum Alloy is injected into the mold at high pressure, which helps to fill the housing's intricate details and thin sections. Maintaining a consistent temperature and pressure is essential to avoid defects such as porosity or incomplete filling.

Cooling and Solidification: Once the molten alloy fills the mold, it must cool and solidify. The cooling rate must be controlled to avoid internal stresses and ensure the structural integrity of the housing. Proper cooling channels within the mold help achieve uniform solidification.

Challenges in Thin Wall Die Casting

Producing thin-walled die-cast components presents several challenges that must be addressed to ensure high-quality results.

Managing Flow and Cooling Rates: Thin walls can cool too quickly, leading to incomplete filling or defects. To manage this, precise control over the flow rate of the molten metal and the cooling rate is necessary. Advanced die-casting machines equipped with real-time monitoring and control systems are used to maintain optimal conditions.

Ensuring Structural Integrity and Avoiding Defects: Thin walls are more susceptible to porosity, warping, and cracking defects. Careful attention is given to the alloy composition, mold design, and casting parameters to counter these issues. Vacuum die casting can also be used to minimize air entrapment and porosity.

Quality Control Measures

Maintaining high quality in die casting requires rigorous inspection and testing at various stages of production.

X-ray Inspection: This non-destructive testing method detects internal defects such as porosity or cracks within the thin-walled sections of the housing.

Dimensional Checks: Precision measurement tools such as coordinate measuring machines (CMM) ensure that the cast parts meet the specified dimensions and tolerances.

Mechanical Testing: Samples from the casting batch are subjected to mechanical tests to verify their strength, hardness, and other relevant properties.

Example of Successful Thin Wall Die Casting

A real-world example demonstrates the success of thin wall die casting using 383 Aluminum Alloy for mini intercom housings. In a recent project, the housing design required walls as thin as 1.5 mm while maintaining structural integrity and precision.

Optimized Mold Design: The mold design was optimized using advanced simulation software to ensure even flow and cooling, reducing the likelihood of defects.

Controlled Casting Parameters: The die-casting machine was programmed with precise temperature, pressure, and cooling rate parameters. It ensured that each housing was produced to the required specifications.

Post-Casting Inspection: Rigorous quality control measures, including X-ray inspection and dimensional checks, confirmed that the housings met the high standards required for telecommunication applications.

Threading and Assembly Preparation

Techniques for Threading Aluminum Die-Cast Parts

Threading is a crucial step in preparing mini intercom housings for assembly. It involves creating internal or external threads on the die-cast aluminum parts to facilitate secure connections with other components. Given the mechanical properties of 383 Aluminum Alloy, specific techniques must be employed to ensure high-quality threads.

Tapping: Taping is commonly used for internal threads. High-speed steel (HSS) or carbide taps are chosen for their durability and ability to maintain sharp cutting edges. The process is carefully controlled to prevent issues like thread galling or tearing, which can compromise the integrity of the threads.

Thread Milling: An alternative to tapping, thread milling offers greater control and flexibility. Using CNC machines, thread milling tools create threads by helical interpolation, producing precise and consistent threads with a lower risk of chip accumulation.

Roll Forming: For specific applications, roll forming (or thread rolling) can create threads without cutting. This method displaces material to form the threads, producing more robust, wear-resistant threads. However, it requires the material to have sufficient flexibility.

Ensuring Thread Integrity and Durability

Thread integrity and durability are essential for the reliable assembly and long-term performance of mini intercom housings. Several practices are implemented to ensure high-quality threads.

Lubrication: Appropriate lubricants reduce friction and heat during threading, preventing tool wear and material damage. It helps achieve smoother, cleaner threads.

Quality Control: Thread gauges and optical inspection systems are used to check the accuracy and consistency of the threads. Any deviations from the specified dimensions are addressed immediately to maintain quality.

Heat Treatment: In some cases, post-threading heat treatment can be applied to enhance the mechanical properties of the threads, making them more resistant to wear and deformation.

Importance of Precision in Threaded Components for Assembly and Functionality

Precision threading ensures that the assembled intercom housing operates reliably and meets performance standards. The following aspects highlight its importance:

Secure Connections: Accurate threads ensure tight connections between components, preventing loosening or misalignment during operation.

Ease of Assembly: Well-formed threads facilitate smoother assembly, reducing cross-threading risk and making the process more efficient.

Performance and Reliability: Precision threads contribute to the overall structural integrity of the housing, ensuring it can withstand the mechanical stresses and environmental conditions it will encounter in use.

Real-World Example of Threading Precision

In a recent production run of mini intercom housings, the threading process required achieving a thread pitch tolerance of ±0.005 mm. Here’s how this precision was achieved:

Advanced CNC Machines: CNC machines equipped with thread milling capabilities created the threads. These machines provided the necessary precision and control to maintain tight tolerances.

Tool Selection and Maintenance: High-quality carbide thread mills were selected for their sharpness and durability. Regular maintenance and inspection of the tools ensured consistent performance throughout the production run.

Real-Time Monitoring: In-process monitoring systems tracked the threading operation, providing real-time feedback on tool wear and thread quality. Adjustments were made as needed to maintain the required tolerances.

Post-Threading Inspection: Each threaded part underwent rigorous inspection using thread gauges and optical systems to verify the dimensions and quality of the threads. Any parts that did not meet the standards were reworked or rejected.

Polishing and Surface Preparation

Polishing Techniques for Aluminum

Polishing is a critical step in the manufacturing process of mini intercom housings, particularly when preparing for surface finishing techniques like PVD (Physical Vapor Deposition). Polishing aluminum involves several techniques to achieve a smooth, defect-free surface.

Mechanical Polishing: This method uses abrasive materials to physically remove imperfections from the surface. Standard tools include rotary buffers, sanding wheels, and abrasive belts. Mechanical polishing is effective for initial rough polishing and removing more significant surface defects.

Chemical Polishing: Involves using chemical solutions to smooth the surface by selectively dissolving high points on the aluminum surface. This method is often used after mechanical polishing to achieve a more uniform finish.

Electropolishing: An electrochemical process that smooths and brightens the aluminum surface by removing a thin material layer. This technique is beneficial for achieving a high-gloss finish and removing microscopic surface irregularities.

Importance of Surface Smoothness for PVD Coating

A smooth, defect-free surface is essential for the success of the PVD coating process. The quality of the PVD finish directly depends on the condition of the substrate. Here's why surface smoothness is crucial:

Adhesion: A smooth surface provides better adhesion for the PVD coating, ensuring it bonds well with the aluminum substrate. Poor adhesion can lead to peeling or flaking of the coating.

Uniformity: Surface irregularities can cause uneven deposition of the PVD coating, resulting in inconsistent thickness and potential weak spots. A polished surface helps achieve a uniform coating layer.

Aesthetic Quality: The appearance of components like mini intercom housings is essential. A smooth surface enhances the visual appeal of the PVD coating, providing a sleek and professional finish.

Quality Checks to Ensure Surface Readiness

Before proceeding with the PVD coating, several quality checks are performed to ensure the surface is adequately prepared.

Visual Inspection: A thorough visual inspection is conducted to identify any visible defects, such as scratches, dents, or rough spots. Any imperfections are addressed through additional polishing.

Surface Roughness Measurement: Tools like profilometers measure the surface roughness to ensure it meets the required specifications. A surface roughness (Ra) of less than 0.2 micrometers for PVD coatings is typically desired.

Cleaning: The polished aluminum parts are meticulously cleaned to remove contaminants, such as oils, dust, or polishing residues. Ultrasonic and chemical cleaning methods are often used to achieve a pristine surface.

Example of Achieving High-Quality Surface Preparation

In a recent project involving mini intercom housings, achieving a high-quality surface finish was critical for the success of the PVD coating. Here's how it was accomplished:

Sequential Polishing: The housings underwent a sequential polishing process, starting with coarse abrasive belts and gradually moving to finer grits. This step-by-step approach ensured the removal of all surface imperfections.

Electropolishing for Final Finish: After mechanical polishing, the parts were subjected to electropolishing to achieve a mirror-like finish. This process enhanced the surface smoothness and prepared it for optimal PVD coating adhesion.

Stringent Quality Checks: Each housing was inspected for surface roughness and cleanliness. Any parts not meeting the stringent criteria were re-polished and cleaned until they passed the inspection.

PVD (Physical Vapor Deposition) Finishing

Explanation of the PVD Process

Physical Vapor Deposition (PVD) is an advanced surface finishing technique for applying thin, high-performance coatings to various substrates. The PVD process involves vaporizing a solid material in a vacuum and then depositing it onto the substrate, forming a thin film.

Vaporization: The coating material, often a metal such as titanium, chromium, or aluminum, is vaporized using thermal evaporation, sputtering, or arc vaporization techniques.

Transportation: The vaporized material travels through a vacuum chamber, ensuring minimal contamination and a clean deposition environment.

Deposition: The vapor condenses onto the substrate (in this case, the aluminum intercom housing), forming a thin, uniform coating that enhances the surface properties of the underlying material.

Benefits of PVD for Aluminum

PVD offers several advantages when applied to aluminum components like mini intercom housings:

Enhanced Durability: PVD coatings significantly improve aluminum's wear resistance and hardness, extending the component's lifespan.

Corrosion Resistance: The coating provides a protective barrier that enhances the aluminum’s natural corrosion resistance, making it suitable for harsh environments.

Aesthetic Appeal: PVD coatings can achieve various finishes, including metallic, matte, and colored appearances, enhancing the visual appeal of the housing.

Eco-Friendly Process: PVD is a clean, environmentally friendly process that produces minimal waste compared to traditional coating methods like electroplating.

Challenges in PVD Processing of Cast Aluminum

Applying PVD coatings to cast aluminum poses unique challenges due to the material’s properties and the casting process:

Surface Preparation: As discussed in Section 6, achieving a perfectly smooth and clean surface is essential for PVD adhesion. Any surface defects or contaminants can lead to coating failures.

Adhesion Issues: The porous nature of cast aluminum can pose adhesion challenges. Proper surface treatment and the use of adhesion-promoting layers are crucial.

Uniform Coating Thickness: Ensuring a uniform coating thickness, especially on complex geometries, requires precise control over the PVD process parameters.

Achieving a High-Quality, Durable Surface Finish

To overcome these challenges and achieve a high-quality PVD finish on cast aluminum intercom housings, several steps and techniques are employed:

Surface Preparation: As highlighted in Section 6, meticulous polishing and cleaning ensure a smooth, contaminant-free surface. This step is critical for successful PVD coating.

Adhesion Layers: Before applying the final PVD coating, an intermediate layer, such as titanium or chromium, may be deposited to enhance adhesion. This layer acts as a bonding agent between the aluminum substrate and the PVD coating.

Optimized PVD Parameters: The PVD process parameters, including temperature, pressure, and deposition rate, are carefully controlled to achieve a uniform coating thickness and optical properties. Advanced PVD systems with real-time monitoring capabilities ensure consistent results.

Quality Assurance: After coating, the housings undergo rigorous quality checks to verify coating thickness, adhesion, and surface finish. Techniques such as X-ray fluorescence (XRF) and scratch testing assess the coating’s integrity and performance.

Example of Successful PVD Coating Application

In a recent project, mini intercom housings required a durable, aesthetically pleasing finish that could withstand harsh environmental conditions. Here’s how the PVD coating process was successfully applied:

Preparation: The aluminum housings were polished to a mirror-like finish and meticulously cleaned to remove all contaminants.

Intermediate Layer: A thin titanium layer was deposited to promote adhesion between the aluminum and the final PVD coating.

PVD Coating: The housings were coated with a titanium nitride (TiN) layer, known for its hardness and gold-like appearance. The process parameters were optimized to ensure a uniform coating thickness of 2 micrometers.

Quality Control: The coated housings were inspected for coating thickness and adhesion. Scratch tests confirmed the coating’s durability, and visual inspections ensured a flawless surface finish.

Overcoming Manufacturing Challenges

Summary of the Main Challenges

Producing high-quality mini intercom housings from 383 Aluminum Alloy involves addressing several critical challenges throughout manufacturing. These challenges include:

Thin Wall Die Casting: Ensuring the structural integrity of thin-walled sections while maintaining dimensional accuracy and preventing defects such as porosity and warping.

High-Precision CNC Machining: Achieving precise tolerances on critical assembly surfaces to ensure seamless fitting and functionality.

Cast Aluminum PVD Processing: Preparing the cast aluminum surface for PVD coating to ensure adhesion, uniformity, and durability.

Solutions and Strategies Implemented to Overcome These Challenges

Advanced Mold Design Techniques

Simulation Software: Using advanced software to optimize mold design for thin-walled sections. It helps predict and address potential issues related to flow and cooling rates, ensuring uniform solidification and reducing the risk of defects.

Precision Mold Fabrication: Employing high-precision machining and fabrication techniques to create molds that produce consistent, high-quality castings.

Precision CNC Machining Practices

Tool Selection and Maintenance: Choosing the right cutting tools, such as high-speed steel or carbide tools, and maintaining them regularly to ensure sharpness and durability. It helps achieve the necessary precision and surface finish.

Optimized Machining Parameters: Carefully select and adjust machining parameters, such as cutting speed, feed rate, and depth of cut, to balance material removal rates and surface quality. It ensures high precision and minimizes tool wear.

In-Process Monitoring: Implementing real-time monitoring systems to track tool wear and machining conditions. It allows for immediate adjustments to maintain accuracy and quality.

Specialized PVD Coating Methods for Cast Aluminum

Surface Preparation: Performing meticulous polishing and cleaning to achieve a smooth, defect-free surface. This step is critical for ensuring the PVD coating adheres appropriately and achieves the desired finish.

Adhesion-Promoting Layers: Applying intermediate layers, such as titanium or chromium, to enhance the adhesion of the final PVD coating. It helps overcome the challenges posed by the porous nature of cast aluminum.

Controlled PVD Process Parameters: Carefully control PVD process parameters, including temperature, pressure, and deposition rate, to achieve uniform coating thickness and optical properties. Advanced PVD systems with real-time monitoring capabilities ensure consistent results.

Real-World Application of Solutions

In a recent project, these strategies were successfully implemented to produce high-quality mini intercom housings for the telecommunication industry. The project involved:

Thin Wall Die Casting: Using advanced simulation software and precision mold fabrication, the team produced thin-walled castings with minimal defects. The final parts demonstrated excellent dimensional accuracy and structural integrity.

High-Precision CNC Machining: Optimized machining parameters, high-quality cutting tools, and real-time monitoring ensured that the critical assembly surfaces met the tolerances of ±0.01 mm. This precision machining enabled seamless assembly and reliable performance.

PVD Coating: After thorough surface preparation and applying an adhesion-promoting layer, the housings were coated with a durable and aesthetically pleasing titanium nitride (TiN) layer. The controlled PVD process resulted in a uniform coating thickness and enhanced surface properties.