How Zinc Die Casting Manufacturer Custom Metal Belt Buckles

Metal Belt Buckles Die Casting Steps

The zinc die casting process is a manufacturing method used to produce metal parts or components, such as custom metal belt buckles, by injecting molten zinc alloy into a mold under high pressure. The process involves several steps:

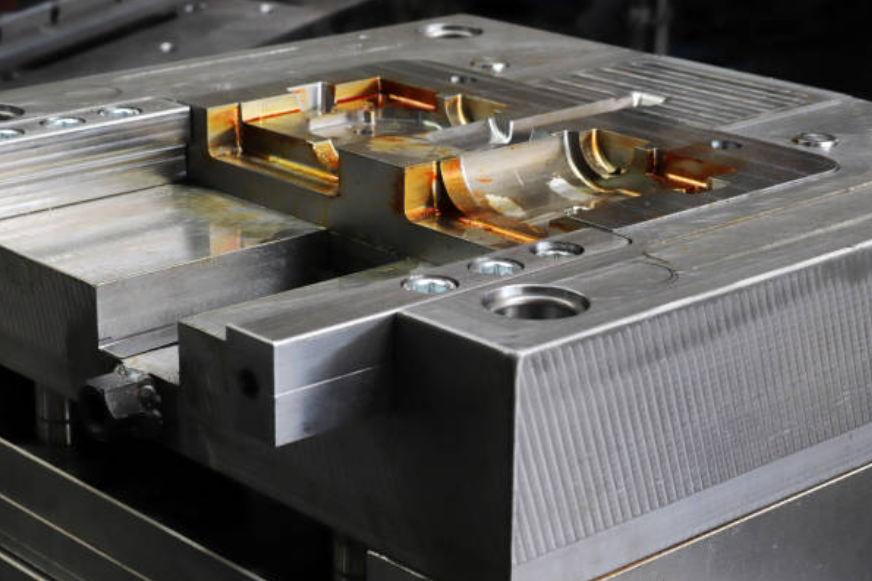

Mold Preparation

Design and fabricate a mold for the custom metal belt buckle. The mold consists of two halves, a cavity in the desired shape of the buckle, and channels for the molten zinc alloy to flow.

Melting and Preparation

Melt the zinc alloy in a furnace at a specific temperature suitable for die casting. The alloy composition is chosen based on the desired properties of the final belt buckle.

Zinc Injection

Place the mold into a die casting machine and close it tightly. The molten zinc alloy is injected into the mold cavity at high pressure, typically ranging from 1,000 to 4,500 pounds per square inch (psi). The pressure ensures that the molten metal fills the entire mold cavity, reproducing the buckle's shape and details accurately.

Cooling and Solidification

Allow the molten zinc alloy to cool and solidify inside the mold. The cooling time depends on the thickness and complexity of the buckle design. Cooling typically occurs rapidly due to the high thermal conductivity of zinc.

Mold Opening and Ejection

Once the metal has solidified, open the mold and remove the newly formed custom metal belt buckle. The mold may have ejector pins or plates to facilitate the ejection process.

Trimming and Finishing

Remove any excess material or flash from the belt buckle using cutting, grinding, or other machining techniques. This step ensures that the buckle meets the required dimensions and surface finish.

Surface Treatment

Apply surface treatments to enhance the appearance and durability of the custom metal belt buckle. This may involve processes such as polishing, plating (e.g., nickel or chrome), painting, or powder coating to achieve the desired aesthetic and protective properties.

Quality Control

Inspect the finished belt buckles for any defects, imperfections, or dimensional inaccuracies. Perform quality control tests to ensure the buckles meet the required standards and functionality.

Assembly

If necessary, assemble additional components, such as prongs or attachments, onto the belt buckle using suitable methods such as welding or fastening.

Benefits of Zinc Die Cast Belt Buckles

Zinc die-casted custom metal belt buckles offer a range of exceptional features and benefits that make them highly desirable accessories. Whether you're seeking custom belt buckles, custom western belt buckles, or custom cowboy belt buckles, zinc die casting provides numerous advantages.

Strength and Durability

Zinc die-casting ensures that custom metal belt buckles are strong and durable, capable of withstanding regular use and the demands of various activities. Whether it's for casual wear or rugged outdoor adventures, zinc die-casted belt buckles offer long-lasting reliability and strength.

But besides zinc alloy die casting, we can also use stainless steel injection molding process to make custom metal belt buckles. Also called MIM Process, stainless steel belt buckles made by MIM are more durable, but relatively more expensive.

Design Flexibility

Zinc die casting allows for intricate and detailed belt buckle designs. Custom belt buckle makers can unleash their creativity to produce unique and eye-catching designs that reflect individual style or brand identity. Custom belt buckle designs can range from classic and elegant to bold and elaborate, providing endless possibilities.

Compared with the MIM and Die casting high-complexity production processes, the metal stamping process can also be used to manufacture metal belt buckles, but it cannot support high-complexity designs.

High Dimensional Accuracy

The die casting process ensures high precision and dimensional accuracy, resulting in custom belt buckles that fit perfectly with belts and accessories. The custom-made belt buckles will seamlessly integrate with the wearer's ensemble, offering a refined and polished look.

Variety of Finishes

Zinc die-casted belt buckles can be finished in various ways, providing a wide range of options to suit personal preferences or specific design requirements. From polished and shiny finishes to brushed or textured surfaces, the possibilities for custom belt buckle finishes are vast. Additionally, the use of plating options such as nickel or chrome enables a touch of elegance and a luxurious appearance.

Corrosion Resistance

Zinc alloys used in die casting exhibit excellent corrosion resistance properties. This feature ensures that custom metal belt buckles can withstand exposure to moisture, humidity, and other environmental elements without significant damage or deterioration. Custom belt buckles retain their appearance and functionality over time, even with regular use and exposure to various conditions.

Cost Efficiency

Zinc is an affordable material, and the die casting process allows for efficient and cost-effective production of custom metal belt buckles. Custom belt buckle makers can deliver high-quality products without compromising on affordability, making custom belt buckles accessible to a wider audience.

Customization and Personalization

Custom-made belt buckles provide a platform for expressing individuality and personal style. Whether it's custom cowboy belt buckles, custom western belt buckles, or any other design, the ability to create unique, one-of-a-kind pieces ensures that the belt buckle is a reflection of personal taste and preferences. For example, pattern customization with laser marking

Why Choose Neway

Try Neway for zinc die-casted custom metal belt buckles that offer exceptional strength, design flexibility, dimensional accuracy, and corrosion resistance. With a variety of finishes and customization options, including custom western belt buckles and custom cowboy belt buckles, individuals can express their unique style.

New customers try us with 20% off your custom metal projects for the first order.