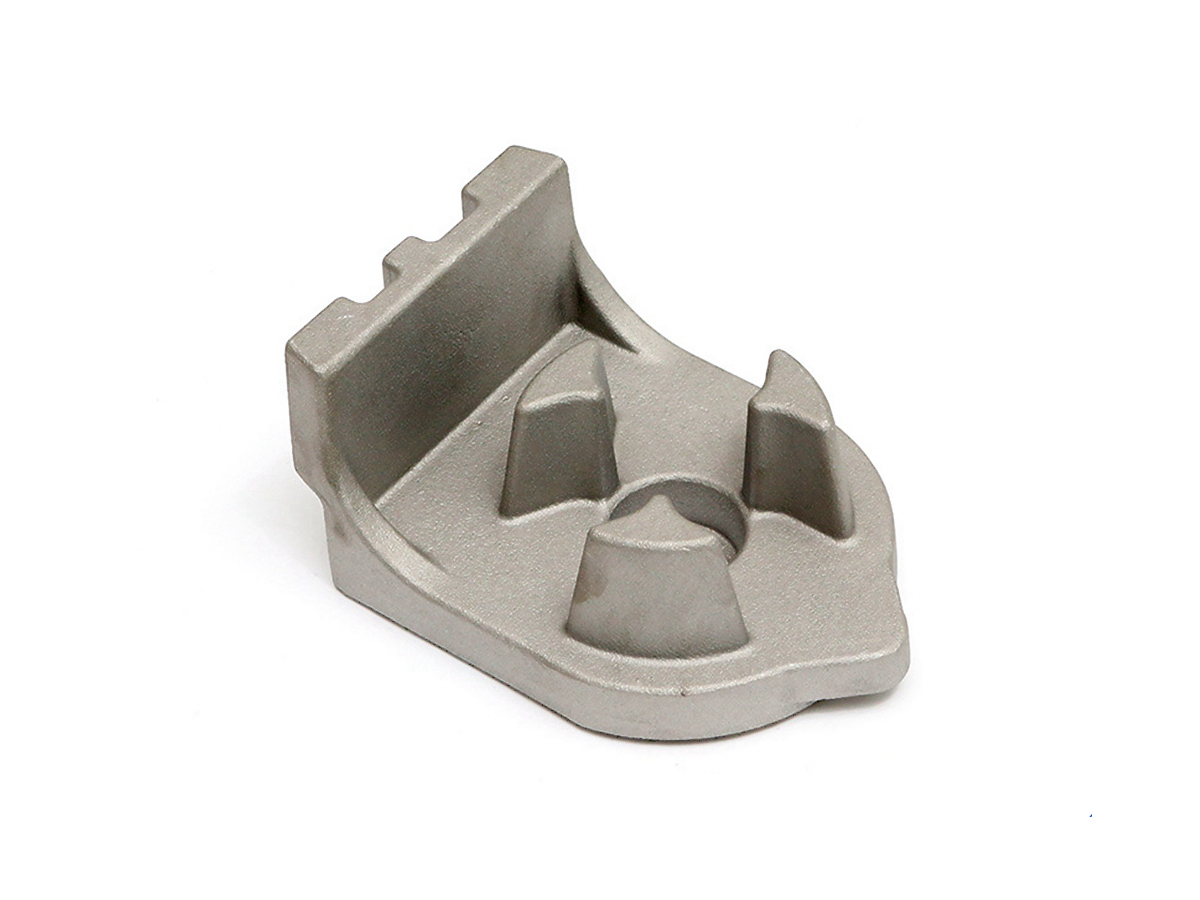

Gravity Casting Driving Automotive Excellence Through Durable Engine Components

Introduction

Gravity casting is essential in the automotive industry, particularly in producing high-performance engine components. This efficient and versatile manufacturing technique involves using gravity to pour molten metal into molds, resulting in precision-engineered automotive parts. As the demand for lightweight, durable, and cost-effective engine components increases, gravity casting has proven to be a reliable solution for automotive manufacturers worldwide.

In this blog, we will explore the gravity-casting process, the materials commonly used in automotive engine components, various surface treatments that enhance performance, and the applications of gravity-cast parts in the automotive industry. By understanding these critical factors, manufacturers can optimize gravity casting to create high-quality engine components contributing to vehicle performance, efficiency, and longevity.

Manufacturing Process of Gravity Casting

Gravity casting is a straightforward yet highly effective manufacturing process that involves pouring molten metal into a mold under the influence of gravity. This process is particularly beneficial for creating complex parts with high precision, such as automotive engine components.

The process begins with creating a mold, typically made from sand or metal, which is designed to precisely match the shape of the component. Molten metal, often heated to temperatures exceeding 700°C, is poured into the mold cavity, filling it completely. Once the metal cools and solidifies, it forms a durable, precise part.

This process is highly efficient for mass production and ensures consistent results. Gravity casting produces parts with tight tolerances, typically within ±0.5% of the nominal dimensions, which is crucial for ensuring a perfect fit and optimal performance in automotive applications. Furthermore, gravity casting is known for producing parts with minimal porosity (less than 0.1%), enhancing the overall strength and durability of the components.

Typical Gravity Casting Materials in Automotive

The success of gravity casting in automotive engine components largely depends on the selection of materials. These materials are chosen based on their ability to withstand high temperatures, maintain durability, and provide the necessary strength-to-weight ratio for optimal engine performance.

A380 Aluminum is one of the most commonly used materials for gravity-cast automotive parts. This aluminum alloy is favored for its excellent castability, high strength, and lightweight properties. A380 has a tensile strength of up to 290 MPa and a hardness of 120 HB, making it ideal for engine components that require both strength and lightness. Additionally, A380 aluminum offers excellent fluidity, ensuring smooth casting and precise part formation.

A356 Aluminum is another highly popular choice in the automotive industry, offering excellent fatigue resistance and strength. This alloy has a tensile strength of 240 MPa, a yield strength of 210 MPa, and a hardness of 110 HB. A356 aluminum can withstand high-temperature environments, making it ideal for engine blocks and pistons that are exposed to extreme heat cycles.

Stainless Steel alloys such as 316L and 304 are commonly used for gravity-casting engine components that require exceptional corrosion resistance and high strength. Stainless steel has a hardness of approximately 200 HB. It maintains its tensile strength of 520 MPa even in harsh environments, which makes it ideal for components exposed to exhaust gases and high-temperature conditions.

Nickel-based Alloys are especially beneficial for high-performance automotive components that operate under extreme heat, such as turbine blades or exhaust system parts. These alloys can endure temperatures above 1000°C and have impressive tensile strengths exceeding 900 MPa. Their resistance to thermal fatigue makes them suitable for components exposed to extreme temperature cycles.

Surface Treatments to Enhance Durability

After gravity-cast engine components are produced, surface treatments are often applied to enhance their performance, appearance, and longevity. These treatments help ensure that parts resist corrosion, wear, and harsh operating conditions.

Anodizing is a widely used treatment for aluminum-based gravity-cast components. This electrochemical process forms a hard oxide layer on the surface, increasing resistance to corrosion and wear. Depending on the alloy and process parameters, the anodized coating improves hardness, with values reaching 250–500 HV (Vickers Hardness). This makes anodized aluminum components highly resistant to abrasion and suitable for high-temperature automotive applications.

Sandblasting is often used to improve the surface finish of gravity-cast components. By using abrasive materials, sandblasting removes defects such as mold marks and ensures a smoother surface. This treatment also promotes better adhesion of paints and coatings. A sandblasted surface typically achieves a roughness profile of around Ra 0.8–3.2 µm, which is essential for enhancing coating effectiveness and durability.

Electropolishing improves the surface smoothness of stainless steel and other metals, making it more resistant to corrosion and reducing material buildup. The electropolished surface has a mirror-like finish and is often smoother than Ra 0.2 µm. It enhances corrosion resistance and reduces the friction between moving parts, which is crucial in engine components like valves and piston rings.

Powder Coating is applied to create a protective layer overcast components, enhancing their resistance to wear and environmental exposure. A powder-coated surface can reach a 50–100 µm thickness, providing long-lasting protection from corrosion, chemicals, and physical wear. This treatment is particularly effective for automotive components exposed to high temperatures and harsh operating conditions.

Advantages of Gravity Casting for Automotive Engine Components

Gravity casting provides several advantages for automotive engine components, making it a highly sought-after manufacturing method. Some of the key benefits include:

Superior Strength-to-Weight Ratio: Gravity-cast aluminum alloys such as A380 and A356 provide an excellent strength-to-weight ratio, which is crucial for improving engine efficiency and vehicle performance. For instance, A380 aluminum’s tensile strength of 290 MPa and density of 2.73 g/cm³ ensure that components are both strong and lightweight, contributing to better fuel efficiency.

Cost-Effective Mass Production: Gravity casting is an efficient process for mass-producing automotive parts. The cost per unit decreases with higher production volumes, making it an attractive option for manufacturers. This is especially important for components like engine blocks and pistons, which are produced in large quantities.

High Precision and Tight Tolerances: Gravity casting offers excellent precision, with typical tolerances of ±0.5% of the nominal dimensions. This ensures that automotive components, especially those critical to engine performance, fit perfectly and operate optimally. Components with tight tolerances reduce the risk of failure and improve overall vehicle reliability.

Enhanced Durability and Performance: High-strength materials such as A380 aluminum and stainless steel, combined with advanced surface treatments, result in durable components capable of withstanding harsh conditions. These parts have high fatigue resistance and can endure the high-temperature, high-stress environments typically found in automotive engines.

Versatility in Complex Designs: Gravity casting is ideal for creating parts with complex shapes and geometries. The ability to produce intricate designs allows for the inclusion of features such as cooling channels or reinforcement ribs in engine components, optimizing performance while minimizing weight.

Considerations in Gravity Casting Production

While gravity casting offers numerous advantages, there are several key considerations to ensure the production of high-quality automotive engine components:

Material Selection: The choice of material is critical for achieving the desired mechanical properties. For example, choosing the right aluminum alloy or stainless steel can affect factors such as tensile strength, hardness, and fatigue resistance. Material selection also impacts the casting process, as different materials have distinct fluidity and cooling characteristics.

Mold Design: The mold's design directly influences the final component's quality. Proper mold design ensures uniform cooling and minimizes defects like porosity or shrinkage. Using advanced computer-aided design (CAD) tools helps optimize mold design for consistent part quality.

Cooling Rates: Cooling rates must be carefully controlled to prevent defects like thermal stress or uneven cooling. For instance, the cooling rate of aluminum alloys such as A356 typically needs to be managed to ensure uniform solidification and minimize internal stresses.

Quality Control: Strict quality control is essential to ensure the performance and reliability of gravity-cast components. Non-destructive testing (NDT) methods, such as X-ray inspection or ultrasonic testing, can detect internal defects like porosity or cracks that could affect the part’s integrity.

Environmental Factors: External factors such as temperature and humidity can influence the casting process. For example, high humidity may affect mold permeability, while temperature fluctuations can lead to uneven cooling. Manufacturers must carefully control environmental conditions to maintain consistent casting results.

Applications of Gravity-Cast Components in Automotive Engines

Gravity casting is widely used in the automotive industry, particularly for producing engine components that demand high strength, durability, and precision. Some common applications include:

Pump and Valve Parts: Gravity-cast components are ideal for producing high-performance pump and valve parts because they handle high pressure and temperature. These parts are essential for engine systems, fuel delivery, and cooling mechanisms.

Automotive Engine Components: Gravity casting is widely used to create critical engine components, including cylinder heads, pistons, and engine blocks. The strength and precision of gravity-cast aluminum alloys make them the material of choice for these demanding applications.

Electric Vehicle Parts: The increasing demand for electric vehicles has led to a rise in the use of gravity-cast components. These parts are used in various areas of electric vehicles, such as battery housings and electric motor casings, where durability, weight reduction, and performance are key considerations.

Wind Turbine Parts: Gravity-cast components, including wind turbines, are increasingly used in renewable energy applications. These parts must be lightweight, corrosion-resistant, and able to withstand harsh environmental conditions, making gravity casting an ideal solution for such components.

Vehicle Parts: Many automotive vehicle parts, from structural components to aesthetic details, benefit from the strength and lightweight properties of gravity-cast materials, contributing to the overall vehicle efficiency and performance.

These gravity-cast components contribute to automotive engines' performance, fuel efficiency, and durability by providing lightweight yet strong and heat-resistant parts.

Related FAQs:

What is gravity casting and how does it work in automotive manufacturing?

Which materials are commonly used for gravity casting in engine components?

What are the advantages of using gravity casting for automotive engine parts?

How does anodizing improve the durability of gravity-cast engine components?

What are the common applications of gravity-cast components in automotive engines?