Energy Sector Innovations: The Role of Laser Cutting in Renewable and Traditional Power Solutions

Introduction

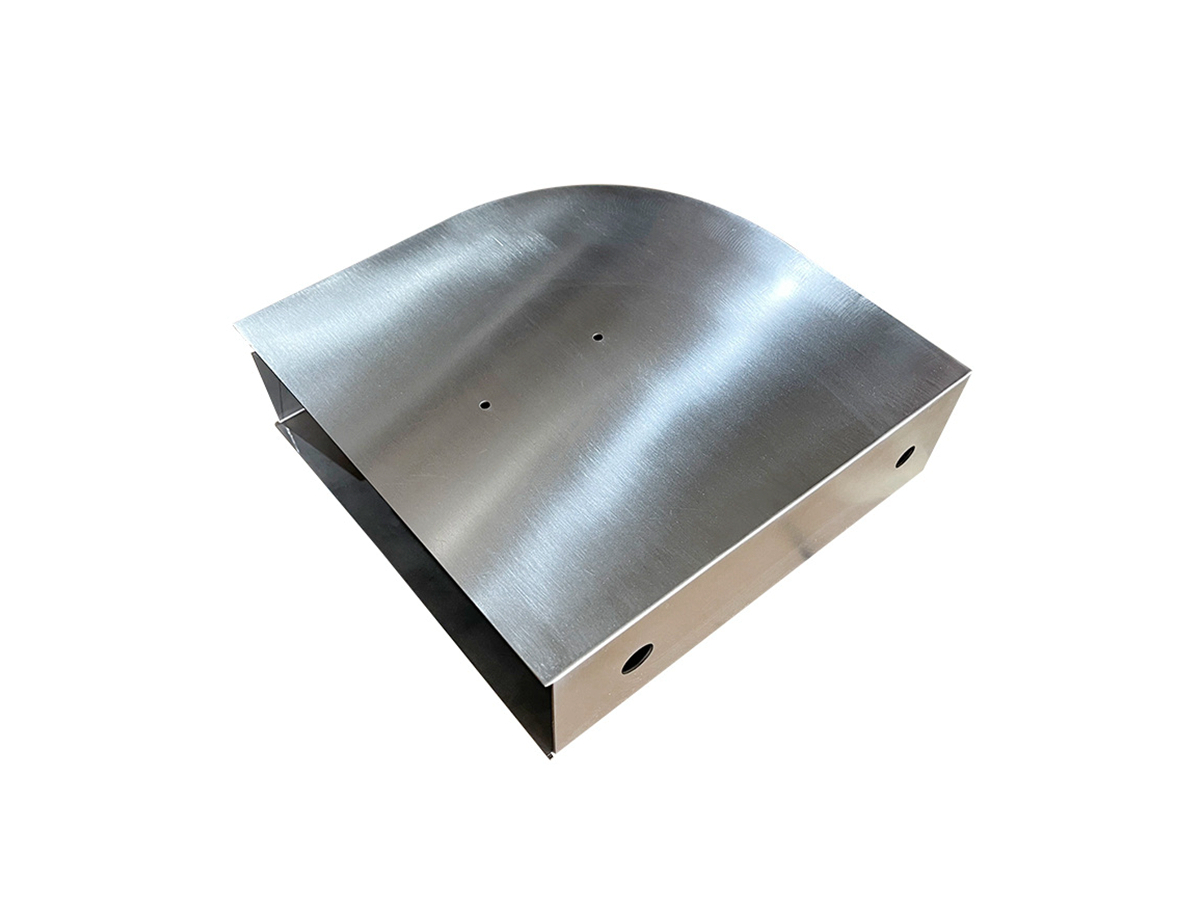

Laser-cutting technology plays a crucial role in the energy sector by providing high-precision solutions for both renewable and traditional power solutions. With its ability to work with various materials and achieve tight tolerances, laser cutting has become an indispensable tool in manufacturing components for power generation, storage, and distribution systems. Laser cutting has been at the forefront of improving manufacturing processes in the energy sector, offering unmatched efficiency and quality in part production.

In both renewable energy sources like wind, solar, hydropower, and traditional power generation systems, laser cutting enhances the production of durable and high-performance components. This technology's efficiency, speed, and versatility ensure that energy solutions meet stringent industry standards while improving overall manufacturing processes.

Manufacturing Process: Step-by-Step Overview of Laser Cutting

Step-by-step breakdown of laser cutting:

Material Preparation: The material is loaded into the laser cutting machine.

Laser Beam Generation: A high-powered laser beam is generated to focus on the material.

Cutting Process: The laser cuts through the material based on programmed patterns.

Cooling and Removal: The cut parts are cooled and removed from the machine.

Typical Laser Cutting Materials in the Energy Sector

Common Materials Used in Laser Cutting for Energy Applications Overview of typical materials used in laser cutting for the energy industry.

Material | Characteristics | Common Applications |

|---|---|---|

Steel | Durable, strong, and versatile | Power plants, turbines, structural components |

Aluminum | Lightweight, corrosion-resistant | Solar panels, energy storage systems |

Stainless Steel | High corrosion resistance, durable | Wind turbines, fuel systems, pipes |

Copper | Excellent electrical conductivity | Electrical components, power cables |

Inconel | High-temperature resistance, strong | Gas turbines, exhaust systems |

Surface Treatment: Enhancing Laser-Cut Parts for the Energy Sector

Painting

Function: Painting enhances the appearance of laser-cut energy components while providing additional protection against environmental factors such as UV rays and corrosion. This is particularly important for components exposed to outdoor conditions.

Characteristics: This surface treatment offers a smooth finish in various colors, ensuring both aesthetic appeal and protection from environmental damage, including UV radiation and moisture.

Use Scenario: Commonly used for renewable energy components like solar panels, wind turbine blades, and outdoor power equipment that need both functional protection and visual appeal.

Electropolishing

Function: Electropolishing improves the surface finish of energy components by removing microscopic imperfections, providing a smoother surface and enhancing corrosion resistance. This is particularly useful for parts used in high-performance environments, such as power plants or energy storage systems.

Characteristics: The process can improve surface roughness by up to 60%, remove surface imperfections by up to 90%, and provide a cleaner, smoother surface.

Use Scenario: Often applied to critical components like fuel cells, power generation units, and heat exchangers, where cleanliness and smoothness are essential for performance.

Powder Coating

Function: Powder coating provides a tough, durable finish that is more resistant to chipping, scratching, and fading than traditional paints. This method uses a dry powder that is applied electrostatically and then cured to create a solid, hard finish.

Characteristics: With a typical thickness of 30-50 microns, powder coating is highly resistant to corrosion, chemicals, and wear. Salt spray test results show up to 1,000 hours of protection against corrosion in harsh environments.

Use Scenario: Ideal for energy components exposed to extreme conditions, such as power generation machinery, solar power frames, and wind turbine structures.

Anodizing

Function: Anodizing increases the thickness of the natural oxide layer on aluminum, improving its resistance to corrosion and wear, and enhancing its appearance with vibrant color finishes. This is particularly important in renewable energy applications.

Characteristics: Anodized parts exhibit enhanced hardness, better corrosion resistance, and improved heat dissipation. Anodized aluminum can withstand salt spray tests for up to 5,000 hours without significant corrosion.

Use Scenario: Anodizing is used in renewable energy applications like solar panels, battery enclosures, and structural components that require strength and corrosion resistance.

Black Oxide Coating

Function: Black oxide coating provides a black matte finish, increasing corrosion and wear resistance. This is useful for energy components that require a protective finish and enhanced performance.

Characteristics: This coating forms a thin, durable layer that doesn’t affect the part's dimensions. It provides moderate corrosion resistance and can be tested for up to 48-72 hours in salt spray tests.

Use Scenario: Commonly applied to parts used in fuel systems, electrical connectors, and valves in both traditional and renewable energy solutions, where protection against wear and corrosion is necessary.

Advantages of Laser Cutting in the Energy Sector

Manufacturing Process | Precision (Tolerance) | Speed (Cutting Rate) | Cost Efficiency | Material Versatility |

|---|---|---|---|---|

Laser Cutting | Up to ±0.1mm | 5–50 m/min (depends on material and thickness) | Moderate | High (Can cut metal, plastic, wood, etc.) |

Up to ±0.01mm | 0.1–10 m/min (depends on tool size and material) | High | Moderate (best for rigid materials) | |

Waterjet Cutting | Up to ±0.2mm | 1–5 m/min (depends on material thickness) | Moderate | High (works with almost any material) |

Precision: Laser cutting offers tolerances as tight as ±0.1mm, making it ideal for producing energy components that require high accuracy, such as turbine blades and solar panel frames.

Speed: Laser cutting is a fast process, with cutting speeds ranging from 5 to 50 meters per minute, significantly reducing production time in the energy sector.

Cost Efficiency: Although laser cutting equipment has an initial investment cost, it significantly reduces material waste and labor costs, offering cost savings for both small and large-scale energy production.

Material Versatility: Laser cutting is effective on various materials, such as metals, plastics, and composites, providing great flexibility for applications in renewable energy, power plants, and electrical systems.

Considerations in Laser Cutting Production for the Energy Sector

Common Production Problems:

Overheating: Can cause material distortion. Solution: Adjust laser power and speed to match material type.

Material Warping: Uneven cutting heat can cause warping. Solution: Use appropriate cooling techniques.

High Tool Wear: Frequent changes to cutting tools. Solution: Maintain and inspect equipment regularly.

Industry Applications of Laser Cutting in the Energy Sector

Renewable Energy: Cutting components for solar panels, wind turbines, and battery storage systems.

Traditional Power Solutions: Manufacturing parts for power plants, boilers, and turbines.

Energy Storage: Producing enclosures, connectors, and battery components.

Oil and Gas: Creating high-performance components for pipelines, valves, and equipment used in oil and gas extraction.

FAQs

How does laser cutting improve the efficiency of energy production?

What materials are used in laser cutting for renewable energy applications?

How accurate is laser cutting for energy sector components?

What are the cost benefits of laser cutting in energy manufacturing?

How does laser cutting reduce material waste in energy production?