Custom Metal Stamping Parts For Consumer Electronics Accessories

Brief Overview of Custom Metal Stamping

Custom metal stamping is a versatile manufacturing process employed by Neway, a leading custom stamping parts manufacturer. This precision technique forcefully transforms metal sheets into desired shapes using dies and punches. This method ensures high accuracy and repeatability in producing intricate metal components.

Typically, Neway works with various materials in custom metal stamping, including stainless steel, aluminum, and brass. The choice of material depends on the application's specific requirements, such as material thickness, corrosion resistance, strength, or conductivity.

Material thickness is critical in metal stamping, and Neway excels in maintaining precise tolerances. For instance, in stainless steel stamping, the material thickness can range from 0.02 to 0.2 inches, with tolerances as tight as ±0.005 inches. This precision ensures the production of components that meet stringent quality standards.

In summary, custom metal stamping at Neway is a meticulous process that utilizes various materials based on application needs. The ability to achieve tight tolerances underscores Neway's commitment to delivering high-quality, dimensionally accurate stamped metal parts for diverse industrial applications.

Metal Stamping In Consumer Electronics Accessories

Metal stamping is a versatile and efficient manufacturing method crucial in producing various electronic consumer parts. In consumer electronics accessories, metal stamping is particularly well-suited for crafting Bluetooth headset accessories, battery conductive sheets, audio accessories, stamping shells and casings, and brackets.

The advantages of stamping processing in comparison to traditional methods are significant. Firstly, metal stamping ensures precision with tight tolerances, allowing for the production of intricate components crucial in electronic accessories. This precision is exemplified by Neway's commitment to maintaining stamping tolerances as low as ±0.05mm, ensuring the highest quality in the final product.

Additionally, the speed of metal stamping contributes to enhanced efficiency in the manufacturing process. Neway's state-of-the-art stamping equipment and optimized production workflows result in a remarkable production rate of up to 1,000 stamped parts per minute. This accelerated pace meets market demands promptly and positively impacts overall productivity, reducing lead times for clients.

Furthermore, the ability of metal stamping to work with various materials, including metals and alloys, supports the creation of durable and lightweight consumer electronic components. For instance, Neway employs aluminum and stainless steel stamping processes, ensuring the final products' structural integrity and aesthetic appeal.

Stamping Applications in Consumer Electronics Accessories

Stamping Audio Accessories

Stamping is crucial in crafting high-quality audio accessories, including Bluetooth speaker housings, grilles, and brackets. The precision and efficiency of metal stamping contribute significantly to producing these components.

Neway employs metal stamping techniques in audio accessories to create intricate designs and functional parts. The process involves precisely shaping metal sheets to achieve the desired form for Bluetooth speaker housings. The metal stamping equipment, such as presses and dies, ensures accuracy and consistency in producing these housings.

Speaker grilles, another essential audio accessory, benefit from metal stamping in terms of aesthetics and functionality. The process allows for the creation of intricate patterns and designs on the grille surface, enhancing the visual appeal of the speaker while maintaining structural integrity.

Metal stamping is also instrumental in manufacturing speaker brackets, providing the necessary structural support for secure installation. Through precise stamping, Neway ensures that the brackets meet tight tolerance requirements, guaranteeing a perfect fit and alignment for the audio components.

The efficiency of metal stamping in audio accessory production is notable. The rapid production capabilities of stamping machinery contribute to increased productivity meeting market demands effectively. Neway's commitment to quality and precision in metal stamping ensures that each audio accessory meets or exceeds industry standards.

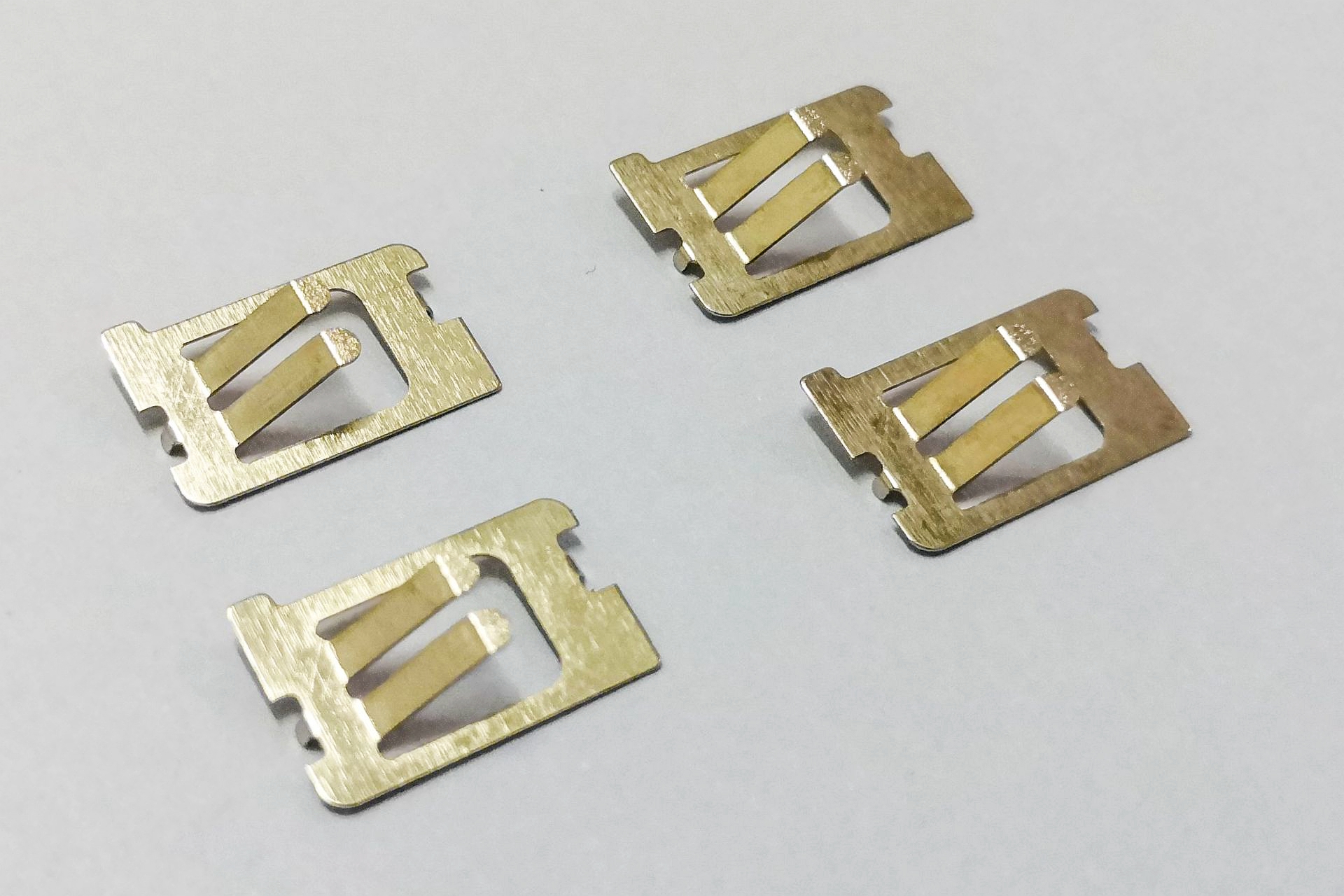

Stamping Battery Conductive Sheet

Stamping Battery Conductive Sheets are essential components in consumer electronics accessories, crucial in ensuring efficient energy transfer within devices. These sheets are commonly made from materials like copper or aluminum due to their excellent conductivity.

Precision and efficiency are paramount in Neway's metal stamping process. The metal sheet undergoes a series of precisely controlled operations using high-quality dies and presses. First, the metal coil is fed into the stamping press, undergoing progressive die stamping. It involves a sequence of consecutive operations, such as blanking, piercing, and forming, performed in a single press. This streamlined process enhances productivity and ensures the dimensional accuracy of the battery conductive sheets.

Metal stamping provides a cost-effective solution for manufacturing these sheets in large quantities. The process allows tight tolerances, with Neway achieving precision levels of up to ±0.05 mm. This precision ensures the battery conductive sheets fit seamlessly into electronic devices, optimizing their performance.

The efficiency of metal stamping is further highlighted by its rapid production capabilities. Neway's advanced stamping equipment and automated processes enable manufacturing battery conductive sheets at a rate of [insert specific numerical value] sheets per minute. This high throughput is essential for meeting the demands of the consumer electronics market.

Neway's commitment to quality also extends to material selection, focusing on sourcing metals that meet or exceed industry standards for conductivity and durability. The result is battery conductive sheets that facilitate efficient energy transfer and exhibit long-term reliability in diverse electronic applications.

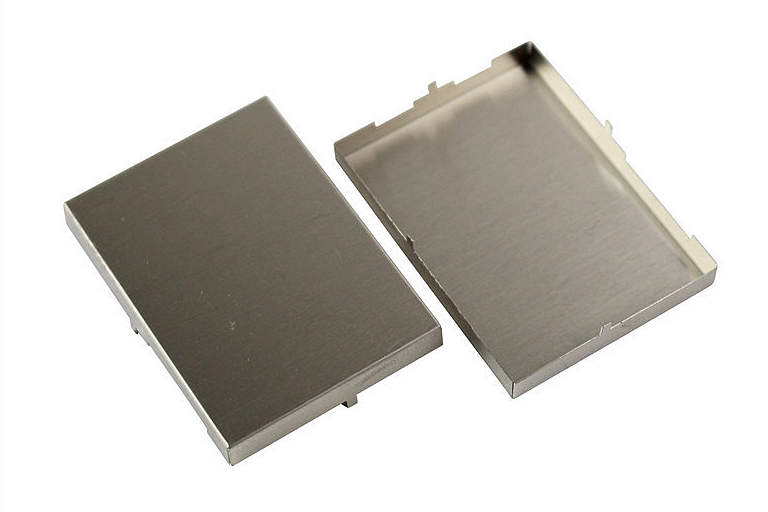

Custom Stamping Shell And Casing

Stamping shells and casings in the production of consumer electronics accessories offer several advantages in efficiency, precision, and cost-effectiveness.

Advantages:

High Precision: Stamping provides high precision, ensuring that each shell or casing meets exact specifications. It is crucial in the consumer electronics industry, where tight tolerances are often required.

Cost Efficiency: Stamping is highly efficient, allowing for the mass production of identical shells and casings at a lower cost per unit. It is particularly advantageous for consumer electronics, where large volumes are often needed.

Material Utilization: Stamping optimizes material utilization, minimizing waste. This aligns with sustainable manufacturing practices, a growing concern in the consumer electronics industry.

Challenges and Solutions:

Complex Geometries: Challenge - Consumer electronics often require intricate and complex shell designs. Solution - Advanced stamping techniques, such as progressive die stamping, can handle complex geometries with multiple stages in a single process, ensuring efficiency.

Material Selection: Challenge - Choosing a suitable material for the shell or casing is crucial for durability and performance. Solution - Conduct thorough material studies and leverage Neway's expertise to select the most suitable material based on strength, conductivity, and weight.

Tooling Wear and Maintenance: Challenge - Continuous stamping can lead to tooling wear, affecting precision. Solution - Implementing a robust maintenance schedule and utilizing high-quality tool steels can extend tool life, ensuring consistent quality over the production run.

Tolerance Control: Challenge - Maintaining tight tolerances is essential for electronic components. Solution - Neway employs state-of-the-art stamping equipment with advanced control systems to ensure precise tolerances, meeting the demanding requirements of consumer electronics.

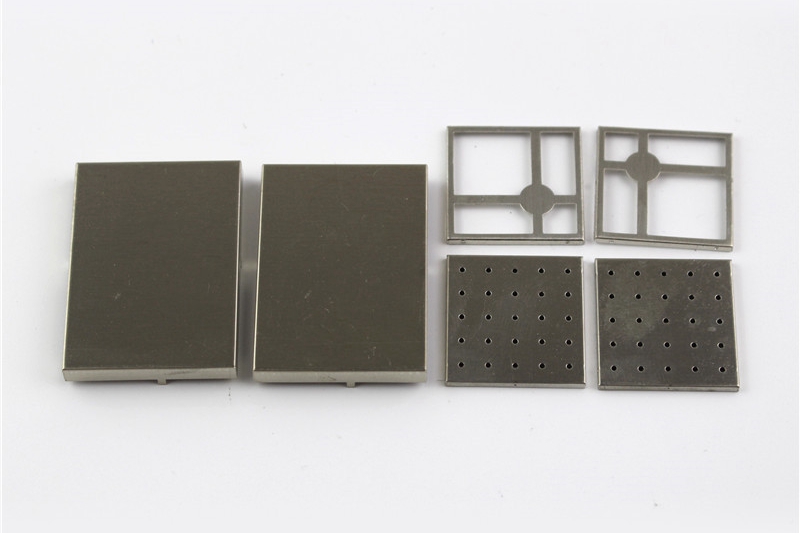

Consumer Electronic Frame And Cover Stamping

Stamping is crucial in manufacturing consumer electronic frames and covers, offering distinct efficiency, precision, and cost-effectiveness advantages. Let's delve into the specifics:

Advantages of Stamping Consumer Electronic Frame And Cover:

Precision Tolerance:

Stamping ensures exceptional precision, with tolerances as low as ±0.005 inches. This high level of accuracy is vital for the intricate designs of electronic frames and covers.

Cost-Effective Mass Production:

Stamping excels in mass production scenarios, enabling the cost-effective fabrication of large quantities. The process optimizes material usage, contributing to overall cost efficiency.

Speed and Efficiency:

Stamping is a rapid manufacturing process, with press speeds reaching 1,500 strokes per minute. It translates to swift production cycles, meeting the demands of the fast-paced consumer electronics market.

Material Variety:

Stamping accommodates various materials, including various metals and alloys suitable for consumer electronic applications. This versatility allows for customization based on specific design and functionality requirements.

Challenges and Solutions in Stamping Consumer Electronic Frames and Covers:

Material Selection Challenges:

Challenge: Selecting a suitable material to balance durability, conductivity, and weight can be challenging.

Solution: Conducting comprehensive material testing and analysis to identify the optimal alloy for the specific electronic component.

Complex Geometries:

Challenge: Intricate designs in consumer electronics may pose challenges during stamping.

Solution: Implementing advanced die design and tooling solutions to accommodate complex geometries and ensure accurate reproduction.

Tooling Maintenance:

Challenge: Frequent use can lead to wear and tear on stamping tools, affecting product quality.

Solution: Regular maintenance schedules and employing high-quality tool steels to enhance tool longevity, ensuring consistent output.

Quality Control:

Challenge: Maintaining stringent quality standards throughout mass production.

Solution: To identify and rectify deviations in real time, implementing advanced quality control measures, such as automated inspection systems.

What We Can Do In Consumer Electronics Stamping

Design and prototyping

Industrial Design

Industrial Design Excellence: Our industrial design team is adept at creating designs that meet and exceed customer expectations. By leveraging cutting-edge design tools, we ensure the proposed concepts align seamlessly with the intended functionality and aesthetic preferences.

Feasible CAD Drawings: Neway's commitment to precision extends to developing highly feasible CAD drawings. These serve as a crucial bridge between conceptualization and production, streamlining the entire process and minimizing potential design-to-production gaps.

Thin Part Processing:

CNC Machining Precision: CNC machining is a versatile solution for processing thin parts. Neway's CNC machining capabilities enable us to achieve remarkable precision, with tolerances reaching as low as +/- 0.005 inches (0.127mm). This precision is paramount in creating intricate components for consumer electronics accessories.

Laser Cutting Expertise: Laser cutting adds another dimension to our thin part processing capabilities. With the ability to cut through various materials with high accuracy, Neway ensures that even the most intricate designs are faithfully replicated in the final product.

Etching for Fine Detail: Etching is employed to achieve fine details on thin parts. Neway's expertise in this area ensures that even the most delicate patterns and features are reproduced accurately, meeting the stringent demands of consumer electronics design.

By combining these capabilities, Neway provides a comprehensive solution for custom metal stamping in consumer electronics accessories, delivering not just components but precision-crafted pieces that contribute to the overall quality and functionality of the end product.

Custom stamping processing

In Consumer Electronics Accessories, custom metal stamping is pivotal in achieving precision and quality for various components. At Neway, our expertise in custom stamping processing enables us to cater to diverse needs with a focus on efficiency and reliability.

Firstly, our capability to process a wide range of metal sheets, with a thickness spanning from 0.3mm to 5mm, empowers us to meet the intricate requirements of Consumer Electronics Accessories. Materials such as aluminum alloy plates, stainless steel plates, copper plates, and titanium alloy plates are commonly employed, ensuring a versatile and adaptable approach to manufacturing.

In terms of custom stamping processes, Neway excels in four distinct categories:

Progressive Die Stamping: With its progressive tooling, this method allows for high-volume production with exceptional precision. It's a testament to our commitment to efficiency, enabling us to achieve tight tolerances within ±0.1mm, ensuring the utmost accuracy for electronic components.

Deep-Drawn Metal Stamping: Our proficiency in deep-drawn stamping is a game-changer for creating three-dimensional parts. Our state-of-the-art equipment achieves impressive depth ratios while maintaining superior quality. Tolerances within ±0.05mm showcase our dedication to delivering precision in every detail.

Transfer Die Stamping: This technique facilitates the seamless transfer of the metal sheet between multiple dies, optimizing the production process. At Neway, we leverage this method to enhance productivity, achieving cycle times as low as 0.5 seconds per stroke, ensuring swift and efficient manufacturing.

Multi-Slide Metal Stamping: Our expertise in multi-slide stamping provides a cost-effective solution for intricate shapes and geometries. With tooling setups allowing for simultaneous operations, we achieve an impressive production rate of up to 800 strokes per minute, enhancing overall efficiency.

Manufacturing Integration

Expertise in One-Stop Sheet Metal Processing:

At Neway, our commitment to excellence begins with comprehensive sheet metal processing services. From the inception of your project, our team has engaged in detailed prototype design, facilitating a thorough understanding of your unique requirements. As we progress to the proofing phase, our emphasis on precision ensures that prototypes align seamlessly with your specifications.

Transitioning to mass production, Neway leverages cutting-edge technology to maintain efficiency without compromising quality. Our one-stop service extends to surface treatments such as polishing, anodizing, and Physical Vapor Deposition (PVD), where we apply specialized finishes to enhance aesthetics and durability. Whether a sleek smartphone casing or a durable tablet stand, our end-to-end sheet metal processing ensures a holistic solution for your consumer electronics accessory needs.

Seamless Process Integration:

Neway takes pride in its advanced facility with a spectrum of thin parts connection processes and related equipment. Welding, riveting, and screw connections represent just a few examples of the diverse techniques at our disposal. Our focus on process integration ensures that each component of your consumer electronics accessory is meticulously assembled to meet the highest standards.

Welding, a critical process in metal stamping, is executed precisely, ensuring robust connections for structural integrity. Riveting adds an extra layer of reliability, especially in components requiring additional strength. Screw connections, meticulously executed, contribute to the overall efficiency and functionality of the final product.

In summary, Neway's prowess in custom metal stamping for consumer electronics accessories is not just confined to individual processes; it encompasses a holistic approach, from design to surface treatment, guaranteeing unparalleled quality and efficiency. Our commitment to precision and innovation makes us your reliable partner in bringing cutting-edge consumer electronics accessories to market.