CIM Parts Manufacturer: Alumina Injection Molding Pump Valve Accessories Manufacturing

Brief overview of CIM (Ceramic Injection Molding)

Ceramic Injection Molding (CIM) revolutionizes the production of intricate ceramic components. Employing a process akin to plastic injection molding, CIM enables the efficient and cost-effective manufacturing of complex ceramic parts with high precision. Finely milled ceramic powders are mixed with binders to form a feedstock, injected into molds, and then subjected to high temperatures for sintering. This method ensures intricate designs, tight tolerances, and superior surface finishes. As a versatile method in Neway's arsenal, CIM allows for creating durable and intricate ceramic components, showcasing the prowess of modern manufacturing in delivering precise solutions for diverse industries.

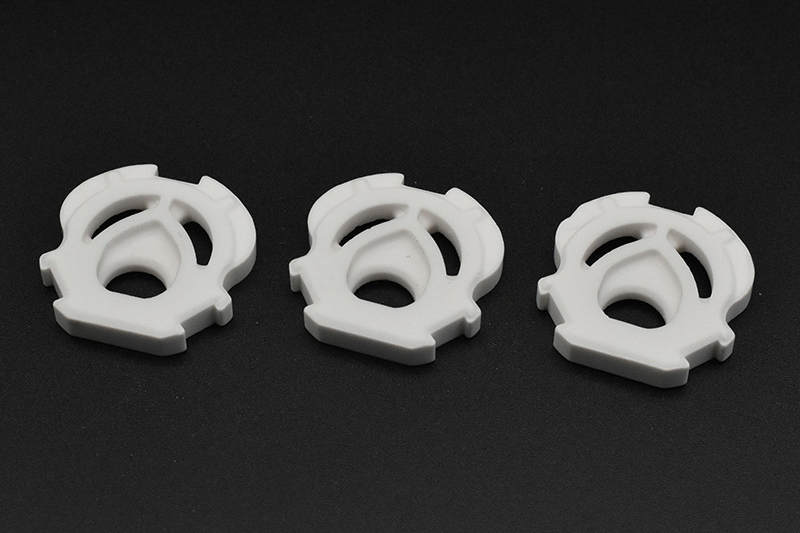

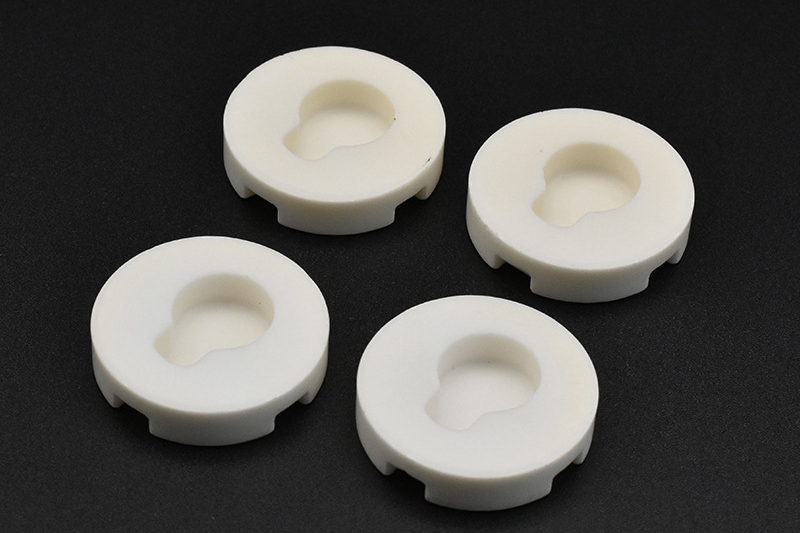

Alumina CIM Parts in Pump Valve Accessories

Alumina, a key material in pump valve accessories, is pivotal in enhancing performance and durability. Leveraging Ceramic Injection Molding (CIM) technology, Neway crafts intricate pump valve components from alumina-based powders, ensuring exceptional hardness, corrosion resistance, and thermal stability. CIM enables the precise formation of complex shapes, enhancing the efficiency of pump valves in critical applications. The sintered alumina parts exhibit remarkable wear resistance, making them ideal for prolonged service in demanding environments. Neway's expertise in CIM and the utilization of alumina underscore the commitment to delivering high-quality pump valve accessories, where the unique properties of alumina contribute significantly to the reliability and longevity of these crucial components.

Advantages of Alumina Injection Molding for Pump Valve Accessories

Alumina injection molding parts play a crucial role in enhancing the performance and durability of pump valve accessories. As a production engineer at Neway, I understand the significance of leveraging advanced manufacturing methods such as Ceramic Injection Molding (CIM) to produce high-quality components. Alumina CIM parts have an irreplaceable position in water purification pumps and valves. Because Alumina CIM parts are not easy to decompose and volatilize toxic substances, they are harmless to the human body. At the same time, it has high-temperature, corrosion, and wear resistance characteristics. It is the first choice for energy, chemical industry, water purification pumps, and valve accessories.

Precision and Complexity:

The CIM process combines the advantages of plastic injection molding with the properties of ceramics. Alumina injection molding allows for creating intricate and exact pump valve components. The molding process enables the production of complex shapes and intricate details that might be challenging to achieve with traditional manufacturing methods.

CIM can manufacture alumina ceramic parts with complex geometric shapes. The accuracy of the blanks has been as high as +/- 3%. After grinding and other post-processing processes, Neway promises to achieve an accuracy of +/-0.01mm.

Material Uniformity:

CIM ensures uniform distribution of alumina ceramic material, resulting in consistent and reliable pump valve accessories. This uniformity is essential for maintaining the structural integrity and performance of the components under diverse operating conditions.

Alumina ceramic pump valve accessories manufactured by the CIM process can ensure that the internal structure of each product is highly uniform and the appearance is highly consistent. Once the mold is confirmed, every CIM part produced is precisely the same.

Cost-Effective Production:

The efficiency of the injection molding process contributes to cost-effectiveness in large-scale production. Neway's expertise in Ceramic Injection Molding (CIM) enables the creation of pump valve accessories with minimal material waste, making it a cost-efficient solution for your manufacturing needs.

The material usage rate of the CIM process is as high as more than 95%. Moreover, ceramic powder's injection and sintering process are highly in line with the automated operation process and are most suitable for producing high-precision, small-volume, and complex-shaped parts.

Enhanced Wear Resistance:

Alumina is known for its exceptional hardness and wear resistance. Pump valve accessories subjected to abrasive conditions benefit from the wear-resistant properties of alumina injection molding parts, ensuring extended service life and reduced maintenance costs.

You can check through Neway's material selector that the hardness of alumina ceramics is as high as HRA85, Compressive Strength 1900 (MPa). It also has the characteristics of working generally at high temperatures. It is the first choice for wear-resistant accessories.

Chemical Resistance:

Pump valve accessories often come into contact with various chemicals in industrial applications. Alumina injection molding parts exhibit excellent chemical resistance, making them suitable for applications where corrosion and chemical interactions are a concern.

Aluminum oxide is an inert material with highly stable chemical properties and does not react with most corrosive chemicals, such as acids and bases, even at high temperatures. At the same time, no toxic substances are volatilized during use. It is the first choice for water purification, the chemical industry, energy pump valves, containers, and pipe fittings.

Tailored Thermal Properties:

Alumina injection molding allows for precise control over the thermal properties of pump valve components. It is essential in applications where temperature fluctuations are typical. The tailored thermal conductivity and heat resistance of alumina enhance the overall reliability of the pump valve system.

Alumina CIM parts can typically work at high temperatures of 1000 degrees Celsius, ensuring their wear resistance and stable chemical properties.

Case Study: Successful Application of Alumina Injection Molding

Alumina Ceramic Injection Molding (CIM) parts play a pivotal role in various industries, providing unparalleled advantages in manufacturing pump valve accessories for applications in the energy sector, chemical industry, and water purification systems.

Alumina CIM Parts in the Energy Sector:

1. Turbine Components:

Alumina CIM parts find extensive use in turbine components within the energy sector. The high hardness and wear resistance of alumina make it an ideal material for components subjected to high-speed rotation and abrasive conditions. CIM allows for intricate designs, ensuring optimal performance in turbine applications.

2. Heat Exchangers:

In energy production, heat exchangers are crucial for efficient thermal management. Alumina CIM parts excel in this application due to their excellent thermal conductivity. The precise molding capabilities enable the creation of intricate heat exchanger components, ensuring enhanced efficiency.

3. Insulating Components:

Alumina's electrical insulating properties make it an ideal choice for manufacturing components in electrical systems within the energy sector. CIM enables the production of complex shapes, facilitating the creation of customized insulating parts for various energy applications.

Chemical Industry Alumina Parts Applications:

1. Chemical Resistant Components:

The chemical resistance of alumina CIM parts makes them invaluable in the chemical industry. Pump valve accessories require materials that can withstand corrosive chemicals, and alumina's inert nature ensures longevity and reliability in these demanding environments.

2. Abrasion-Resistant Pump Components:

Alumina CIM parts are utilized to manufacture pump components that handle abrasive chemicals. The alumina's exceptional hardness enhances these parts' wear resistance, resulting in extended service life and reduced maintenance costs for pumps in chemical processes.

3. Precision Components for Metering Pumps:

CIM allows for producing exact and intricate components essential for metering pumps in the chemical industry. The ability to achieve tight tolerances ensures accurate and reliable dosing of chemicals, contributing to the efficiency of chemical processes.

CIM Alumina Parts in Water Purification Systems:

1. Filtration System Components:

Alumina CIM parts are crucial in producing components for water purification systems, particularly in filtration applications. The material's inert nature ensures it does not contaminate the purified water, making it suitable for critical components in these systems.

2. High Pressure and Temperature Resistance:

Pump valve accessories in water purification systems often operate under high pressure and temperature conditions. Alumina CIM parts excel in these environments, providing mechanical strength and thermal stability for reliable and durable performance.

3. Chemical Stability in Water Treatment Processes:

Alumina's resistance to chemical reactions makes it an ideal choice for components involved in water treatment. CIM enables the production of customized parts that meet the specific requirements of water purification processes, ensuring the delivery of clean and safe water.

CIM Material Classification and Selection

In addition to alumina ceramic injection molding, Neway also offers a variety of ceramic material options. Due to the particularity of CIM ceramic powder, Neway can customize unique materials for injection molding and sintering services according to the needs of customer products. Mainly the following types:

CIM Alumina (Al2O3)

Ceramic Injection Molding (CIM) using alumina (Al2O3) materials presents a unique set of characteristics that make it highly sought after in various industries. Alumina, known for its exceptional hardness, wear resistance, and thermal stability, is an ideal choice for components subjected to demanding conditions. The CIM process allows for intricate and precise designs, enabling the production of complex shapes with tight tolerances.

In terms of characteristics, alumina CIM parts exhibit excellent mechanical strength, corrosion resistance, and electrical insulation properties. These qualities make them indispensable in durable applications like pump valve accessories. The ability to withstand extreme temperatures and harsh chemical environments positions alumina CIM parts as critical components in the energy, chemical, and water purification industries.

Alumina-Zirconia

Ceramic Injection Molding (CIM) incorporating alumina zirconia materials combines the unique properties of alumina (Al2O3) and zirconia (ZrO2), resulting in a versatile and high-performance material. This composite exhibits a balanced blend of hardness, wear resistance, and toughness. Alumina contributes exceptional hardness and wear resistance, while zirconia enhances toughness and resistance to thermal shock. The CIM process allows for the precise formation of complex shapes with these superior material properties.

Typical applications of Alumina-Zirconia CIM materials span various industries, including aerospace, medical, and electronics. In aerospace, these materials find use in components demanding high wear resistance and the ability to withstand extreme conditions. In the medical field, alumina-zirconia CIM parts are employed in implants and surgical instruments where biocompatibility and durability are crucial. In the electronics industry, these materials are valued for their electrical insulation properties, making them suitable for components in demanding electronic devices. Combining alumina and zirconia in CIM creates a material that excels in diverse applications, making it a go-to choice for industries requiring high-performance ceramic components.

Silicon Carbide (SiC)

Ceramic Injection Molding (CIM) utilizing Silicon Carbide (SiC) materials presents a compelling combination of properties that make it well-suited for challenging applications. Silicon Carbide is renowned for its exceptional hardness, high thermal conductivity, and resistance to corrosion and wear. The CIM process allows for precisely forming intricate shapes with these superior material characteristics.

Typical applications of CIM Silicon Carbide materials extend to industries such as automotive, aerospace, and electronics. In automotive applications, SiC components contribute to increased fuel efficiency and reduced emissions due to their lightweight nature and high thermal conductivity. In aerospace, Silicon Carbide CIM parts find use in components subjected to extreme temperatures and harsh environmental conditions, ensuring reliable performance. SiC materials are valued in electronics for their thermal management properties, making them suitable for applications where heat dissipation is critical. The versatility of CIM Silicon Carbide materials positions them as essential components across industries demanding high-performance ceramic solutions.

Silicon Nitride (Si3N4)

Ceramic Injection Molding (CIM) with Silicon Nitride (Si3N4) materials offers unique characteristics that make it highly sought after in various industrial applications. Silicon Nitride, known for its exceptional strength, hardness, and resistance to wear, makes it an ideal choice for demanding environments. Its high-temperature stability and excellent thermal shock resistance position CIM Si3N4 parts as reliable components in industries with extreme conditions.

Typical applications of CIM Silicon Nitride materials include components in the automotive and aerospace sectors, where the need for lightweight, durable, and high-performance parts is crucial. Additionally, the excellent thermal and chemical resistance of Si3N4 makes it suitable for applications in the energy sector, such as turbine components. In summary, CIM Si3N4 materials find their niche in applications demanding strength, durability, and resistance to harsh conditions.

Zirconia (ZrO2)

Ceramic Injection Molding (CIM) Zirconia (ZrO2) materials possess unique characteristics that make them highly sought after in various industrial applications. Zirconia is a versatile ceramic material known for its exceptional hardness, wear resistance, and high-temperature stability. These properties make CIM Zirconia parts ideal for demanding environments where durability is paramount. In addition to its mechanical robustness, Zirconia exhibits excellent corrosion resistance, making it suitable for applications exposed to harsh chemicals or corrosive substances.

CIM Zirconia materials are widely used in engineering components requiring high precision and dimensional stability. Their low thermal conductivity and resistance to thermal shocks make them well-suited for applications in extreme temperature conditions. Industries such as aerospace, medical, and electronics benefit from CIM Zirconia's ability to withstand aggressive operational environments. From intricate components in medical devices to wear-resistant parts in electronic equipment, the adaptability of CIM Zirconia materials enhances the reliability and longevity of various products.

Custom CIM Materials

Ceramic Injection Molding (CIM) Custom materials boast exceptional properties ideal for various applications. Typically, CIM materials exhibit high strength, excellent wear resistance, and superb thermal stability. These materials are adept at withstanding extreme temperatures and harsh chemical environments, making them a go-to choice in demanding industries. Moreover, CIM Custom materials offer intricate design capabilities, allowing for complex shapes and fine details that are challenging to achieve through conventional manufacturing methods.

These attributes find wide applications across diverse industries. CIM Custom materials are extensively used in manufacturing components for electronics, such as insulators and electrical housings, due to their excellent dielectric properties. Additionally, they're pivotal in creating wear-resistant components for industrial machinery, high-temperature furnace parts, and even medical implants, owing to their biocompatibility and durability. Their ability to endure corrosive environments makes CIM materials invaluable in chemical processing equipment and components for water purification systems, including pump valve accessories.