Anodized Aluminum Die Casting LED Lighting Lamp Shell/Housing Manufacturing

Importance of Anodized Aluminum Die Castings

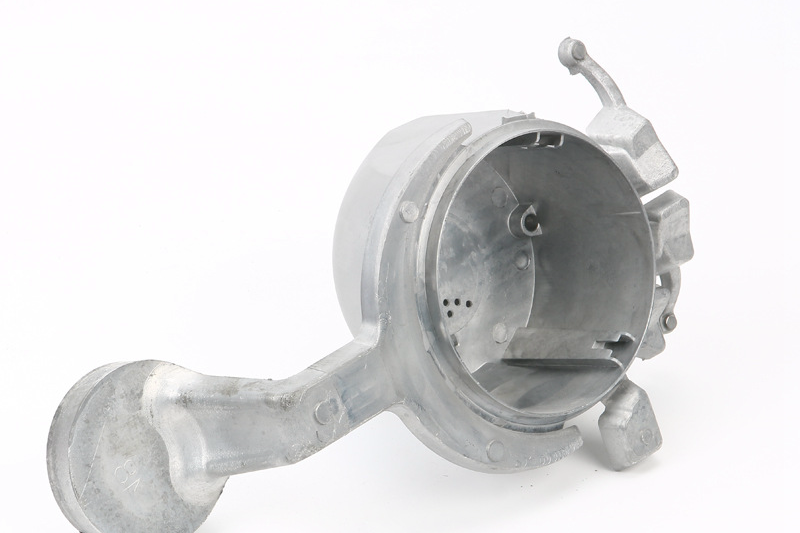

Anodized Aluminum Die Casting LED Lighting Lamp Shells/Housings play a pivotal role in the Lighting Solutions industry. These components are instrumental in ensuring LED lighting systems' longevity, durability, and overall performance.

First and foremost, the anodized aluminum die-casting process adds a protective layer to the lamp shell, enhancing its resistance to corrosion, wear, and environmental factors. It is a game-changer in the lighting industry, where products often endure harsh conditions. It ensures that LED lamps maintain functionality even in outdoor or high-moisture settings, such as street lighting or underwater installations. Neway's commitment to precision in die casting ensures that these lamp shells offer superior protection, making them a top choice for demanding applications.

Moreover, the lightweight nature of anodized aluminum benefits the energy efficiency of LED lighting systems. Reduced weight translates into lower shipping costs and easier installation while maintaining structural integrity. Neway's expertise in aluminum die casting ensures that these lamp shells are lightweight and retain their high precision, a vital factor in achieving optimal light distribution and performance in lighting solutions.

Understanding Die Casting

Die casting is a high-precision manufacturing process that produces complex, intricately detailed, and geometrically precise metal components, such as aluminum parts for the Lighting Solutions industry. At its core, die casting involves forcing molten metal into a reusable mold cavity, referred to as a die, under high pressure. This process stands out for its ability to create parts with beautiful details and thin walls. It is a go-to method for manufacturing intricate components like lighting lamp shells and housings.

The die-casting process begins with melting the chosen metal, usually aluminum, in a furnace. Once molten, the metal is injected into the die under substantial pressure. This pressure, often delivered by a hydraulic press, ensures that the molten metal precisely fills the mold cavities. The die is a carefully crafted mold designed to mirror the desired shape and features of the final part. The mold is opened after the metal cools and solidifies within the die, revealing the now-solidified component.

Die casting is a highly efficient process for producing high-precision components with minimal waste. It is particularly well-suited for the lighting industry due to the intricate and lightweight designs required for modern LED lighting solutions. Neway's expertise in aluminum die casting has positioned them as leaders in this field, enabling the production of top-quality lighting components that meet the industry's demanding standards for performance, durability, and aesthetic appeal.

Advantages of Die Casting

Die casting offers remarkable advantages in manufacturing lamp shells and housings, making it an ideal choice for the Lighting Solutions industry. Firstly, die casting ensures exceptional precision, with tolerances as tight as ±0.02 mm, resulting in flawless and high-precision lamp components.

Secondly, die-casting materials, especially aluminum, are lightweight yet durable, providing excellent heat dissipation properties. It is vital for lamp shells as it helps prevent overheating, extending the lifespan of LED bulbs and enhancing overall safety. Additionally, aluminum lamp housings are corrosion-resistant and essential for outdoor lighting applications, ensuring longevity even in harsh environments.

Lastly, die casting allows intricate and complex designs to be manufactured efficiently. It is especially advantageous for creating aesthetically pleasing lamp casings with unique patterns and shapes. The process offers excellent repeatability, ensuring consistency across a production run, which is essential in the lighting industry, where uniformity is often required for multiple fixtures in a space.

Aluminum As the Material of Choice

Aluminum is the premier choice for die-casting LED lamp shells and housings due to its exceptional properties that align perfectly with the rigorous demands of the Lighting industry. First and foremost, aluminum is renowned for its remarkable lightweight yet sturdy nature, making it an ideal candidate for LED lamp casings. This lightweight attribute significantly reduces the overall weight of the lamps, enhancing portability and installation ease.

Moreover, aluminum boasts excellent thermal conductivity, a vital feature for LED lighting solutions. With the increasing focus on energy efficiency, LEDs generate heat, which needs efficient dissipation. Aluminum's superior thermal conductivity efficiently disperses this heat, preventing overheating and extending the LED's lifespan. This property enhances the LED's performance and contributes to its longevity, paramount for manufacturers and end-users.

Furthermore, aluminum die-casting facilitates intricate and precise designs. For instance, in the Lighting industry, where aesthetics and functionality are pivotal, aluminum allows for intricate detailing while maintaining the highest precision. The ability to craft intricate designs with precision down to micrometers ensures that LED lamp shells and housings look elegant and serve their purpose flawlessly, whether for residential, commercial, or industrial lighting solutions.

Die Cast Aluminum Alloy Optional

In die-casting LED lamp shells and housings, the choice of specific aluminum alloys plays a critical role in achieving the desired performance and durability. Among the various aluminum alloys available, two prominently stand out: ADC12 and A380.

ADC12, an aluminum alloy primarily composed of aluminum, silicon, and a trace amount of copper, is widely favored for its superb fluidity during die-casting. This exceptional fluidity allows for intricate and precise casting, resulting in finely detailed lamp shells and housings that meet the stringent requirements of the Lighting industry. ADC12's impressive corrosion resistance ensures the longevity of the LED lamps, even in challenging environments.

On the other hand, the A380, which features a composition of aluminum, silicon, and zinc, is known for its remarkable combination of strength and flexibility. This alloy is particularly popular when durability is of utmost importance. A380-based LED lamp housings excel in impact resistance and can withstand the rigors of both indoor and outdoor applications.

Die Castings Anodization Process

Anodizing is a specialized surface treatment process that plays a crucial role in the Lighting industry, significantly enhancing the performance and aesthetics of aluminum die-cast components, such as LED lamp shells and housings. This electrochemical process involves the controlled oxidation of the aluminum's surface to create a durable and corrosion-resistant layer.

During anodizing, the aluminum component is immersed in an electrolyte bath and subjected to an electric current. It prompts the formation of an oxide layer on the aluminum's surface, typically known as an anodic oxide coating. The thickness of this coating can be precisely controlled, which is vital in the Lighting industry for achieving specific requirements. Anodized coatings can vary in thickness from a few micrometers to tens, providing excellent protection and customization options.

The advantages of anodizing are manifold. It enhances the aluminum's natural corrosion resistance and creates an excellent base for coloring and further surface finishing. The anodic oxide layer can be dyed in various colors to meet aesthetic preferences, making it an attractive choice for LED lamp shells and housings. Additionally, the process ensures that the aluminum retains its lightweight nature, an essential characteristic for lighting solutions.

Advantages of Anodized Die Castings

Anodized aluminum offers many advantages that make it a preferred choice for various applications in the Lighting industry, including LED lamp shells and housings. First and foremost, anodized aluminum boasts exceptional corrosion resistance. The anodic oxide layer created during the anodizing process is a barrier, preventing moisture and environmental factors from corroding the underlying aluminum. This corrosion resistance is particularly crucial for outdoor lighting solutions, ensuring the longevity and durability of LED lamp housings.

Another critical advantage of anodized aluminum is its enhanced durability. The anodic oxide coating forms a hard, protective surface that significantly increases the aluminum's resistance to wear and abrasion. It is significant for LED lamp components exposed to handling, installation, and other mechanical stresses, ensuring their continued performance and appearance over time.

Furthermore, anodizing offers outstanding customization possibilities. The process allows for the application of various colors, enabling designers to match LED lamp shells and housings with specific aesthetics or branding requirements. Additionally, the precise control over the thickness of the anodic layer ensures that the material's lightweight nature is preserved, which is essential for lighting solutions.

Lamp Shells/Housings Case Studies

Neway is a renowned custom aluminum die-casting parts manufacturer that produces LED lighting lamp shells and housings. With a profound commitment to quality, precision, and innovation, Neway has become a key player in the Lighting Solutions industry.

At Neway, we employ cutting-edge technology and expertise to deliver anodized aluminum die-casting solutions that meet the highest industry standards. Our one-stop service encompasses the entire production process, from rapid prototyping, including CNC machining, rapid molding, and 3D printing, to the meticulous aluminum die-casting process. We are known for our unparalleled precision, with tolerances as low as a mere 0.02mm, ensuring that each product meets exacting specifications.

One of Neway's core strengths lies in its ability to offer surface treatment services that enhance the lamp shells' aesthetics and provide added durability. Our anodized aluminum die-casting creates a sleek, corrosion-resistant finish and supports the LED's thermal management, thus prolonging the lamp's lifespan. We take pride in our contributions to the Lighting industry, consistently pushing boundaries to create efficient and visually appealing lighting solutions. With Neway, you can expect the perfect synergy of advanced technology and precision craftsmanship, resulting in LED lighting lamp shells and housings that are both functional and aesthetically pleasing.

Challenges And Solutions

Manufacturing anodized aluminum die-casting LED lighting lamp shells, and housings presents several key challenges, but with Neway's expertise and commitment to excellence, these challenges can be expertly addressed.

1. Complex Geometries and Precision Requirements:

Challenge: The Lighting industry often demands unique and intricate lamp shell designs. These complex geometries can pose a challenge during manufacturing, particularly when maintaining tight tolerances. Ensuring that the final product aligns perfectly with the design specifications is critical.

Solution: Neway excels in precision, thanks to a combination of advanced technologies. Our rapid prototyping services, including CNC machining prototyping and 3D printing, enable us to transform complex designs into physical prototypes with astounding accuracy. We take pride in controlling precision values down to 0.02mm, guaranteeing that every angle and dimension aligns perfectly with the intended design.

2. Thermal Management for LEDs:

Challenge: LED lighting technology's efficiency is closely tied to its ability to manage heat effectively. Without proper heat dissipation, LEDs can overheat, leading to reduced lifespans and diminished performance.

Solution: Neway's anodized aluminum die-casting process is a game-changer in thermal management. The anodized surface enhances the lamp's appearance and significantly improves heat dissipation. By conducting heat away from the LED efficiently, our lamp shells and housings extend the lifespan of the embedded LEDs. It is paramount in the Lighting industry, where longevity and consistent performance are essential.

3. Surface Finish and Corrosion Resistance:

Challenge: The appearance and durability of lamp shells and housings are vital in the Lighting industry. Maintaining a pristine surface finish while ensuring corrosion resistance is a demanding task.

Solution: Neway's anodized aluminum die-casting process stands out in this regard. Not only does it create a visually appealing surface finish, but it also offers excellent corrosion resistance. Our expertise ensures the surface treatment remains unblemished even when exposed to challenging environmental conditions. This level of quality not only adds to the product's overall aesthetics but also ensures its longevity, a crucial factor in lighting solutions where products are often exposed to various elements.

4. Sustainability and Environmental Concerns:

Challenge: The global shift towards sustainability necessitates that manufacturers minimize waste and energy consumption in their processes.

Solution: Neway is fully committed to eco-friendly practices. We employ efficient casting techniques that minimize material waste. Additionally, our anodizing process adheres to stringent environmental regulations, ensuring it is a responsible and sustainable approach. By providing long-lasting LED lamp shells and housings, Neway contributes to reduced energy consumption in the Lighting industry, aligning with the broader goal of environmental sustainability.

Surface Treatment Techniques

Regarding surface treatment options for LED lighting lamp shells and housings, powder coating and anodizing are two prominent choices. These methods offer distinct advantages, and Neway, as a leading manufacturer, excels in both techniques to meet the diverse needs of the Lighting industry.

Powder Coating:

Powder coating is a versatile and environmentally friendly surface treatment option. In this process, a dry powder is applied electrostatically to the lamp shell or housing and then cured through heat, creating a durable, uniform finish. Powder coating is available in a wide range of colors and finishes, providing ample room for customization to match the desired aesthetics of the product. This method offers excellent corrosion resistance and can withstand various environmental conditions, making it ideal for outdoor lighting applications. Furthermore, powder coating allows for intricate designs and patterns, enhancing the lamp's visual appeal. Neway's expertise in powder coating ensures that lamp shells and housings look great and perform exceptionally in terms of durability and protection.

Anodizing:

Anodizing is another premium surface treatment technique. It involves electrochemically enhancing the natural oxide layer on aluminum to create a rigid, corrosion-resistant surface. Anodized lamp shells and housings are known for their sleek appearance and superior thermal management properties. The anodized layer provides a visually appealing finish and supports efficient heat dissipation, which is crucial for the longevity of embedded LEDs. Anodizing can be tailored to achieve different colors and finishes, ensuring the final product aligns with the desired design aesthetics. Neway's mastery in anodizing guarantees that lamp shells and housings meet the visual and functional requirements and stand the test of time.

The choice between powder coating and anodizing depends on the project's requirements. Powder coating excels in color options and impact resistance, making it an excellent choice for decorative or outdoor applications. On the other hand, anodizing offers outstanding durability, corrosion resistance, and thermal management properties, making it the preferred choice when LED longevity and performance are paramount. As a leading manufacturer, Neway leverages its expertise to provide surface treatment options, ensuring that our clients can select the most suitable finish for their LED lighting lamp shells and housings.

Neway's Expertise In Manufacturing

Neway, as a die-casting manufacturer, factory, and supplier, has cultivated a reputation for excellence across multiple facets of our business, showcasing our unwavering commitment to aluminum die casting, surface treatment, quality control, and customer focus.

Aluminum Die Casting Expertise:

Our profound expertise in aluminum die casting is at the core of Neway's capabilities. We have honed our skills over years of dedication to precision and innovation. Our one-stop service, encompassing rapid prototyping, CNC machining, 3D printing, and aluminum die casting, allows us to take a project from concept to completion seamlessly. Our state-of-the-art equipment and a team of skilled engineers have achieved remarkable precision, with tolerances as low as 0.02mm. This expertise ensures that the LED lighting lamp shells and housings we produce for the Lighting industry adhere to the strictest specifications.

Surface Treatment Excellence:

Neway's commitment to quality extends to surface treatment. We offer powder coating and anodizing options, allowing our clients to choose the ideal finish for their products. Our anodized aluminum die casting enhances the visual appeal and supports critical aspects of performance, such as thermal management for LED lighting. We understand that the surface finish is a critical factor in the Lighting industry, and our expertise in this area ensures that our products look outstanding and withstand the test of time, even in demanding environments.

Stringent Quality Control:

Quality control is the cornerstone of our operations. We employ rigorous quality assurance protocols at every stage of manufacturing. Our commitment to precision and consistency is unwavering from initial design and prototyping to the final product. We utilize advanced inspection equipment to guarantee that each lamp shell and housing meets the highest standards. Our dedication to quality control is underpinned by adherence to international quality management standards, giving our clients peace of mind when they choose Neway for their die-casting needs.

Customer Focus:

Neway places customers at the center of our operations. We understand that each project is unique, and we take pride in tailoring our solutions to meet specific requirements. Our communication is clear and responsive, ensuring that our clients are informed at every stage of the production process. We collaborate closely with clients, providing valuable insights and suggesting necessary improvements. Our commitment to customer satisfaction extends beyond the project's completion; we stand by our products, offering post-sales support to address any concerns or inquiries.

Brand Case Study

Neway has served many world-renowned companies, using its strong manufacturing capabilities and complete quality control system to provide further market competitiveness and quality assurance for major brands.