On-Demand Production Capabilities

Neway is a professional custom parts manufacturer. Specialized in offering:

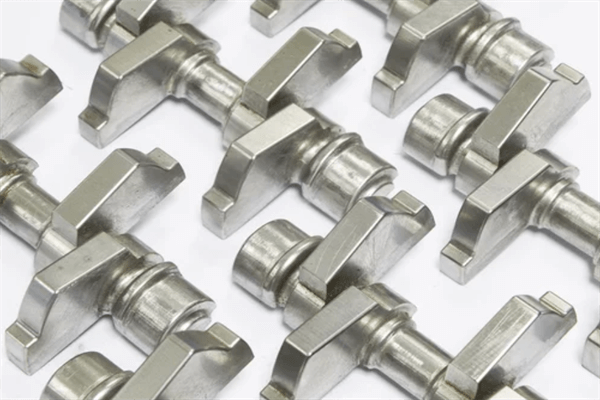

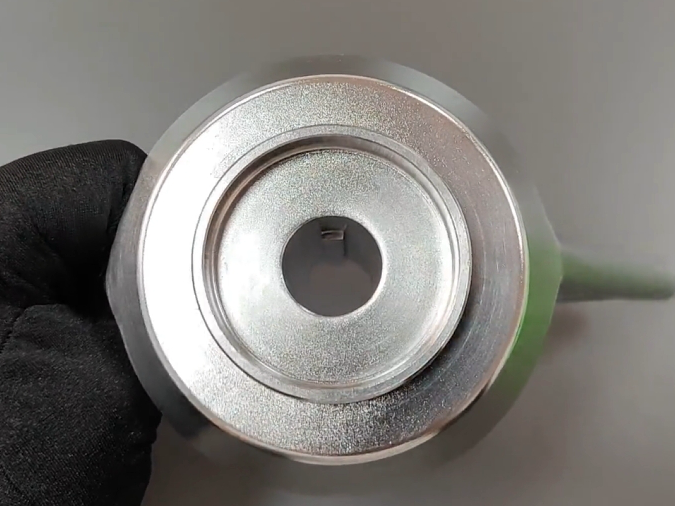

1. Metal injection molding service (MIM)

2. Ceramic injection molding service (CIM)

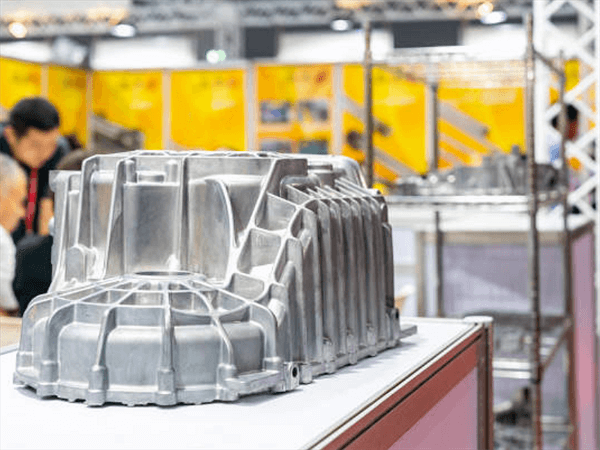

3. Aluminum & Zinc alloy die-casting service

4. Plastic injection molding service

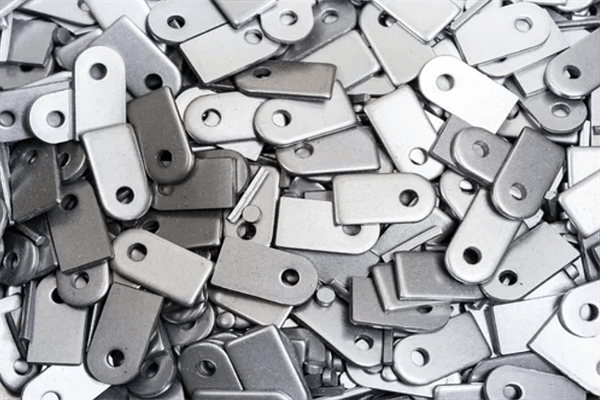

5. Sheet metal fabrication service

Neway On-Demand Production Service and Assurance

Need reliable, high-quality production services without the hassle? Look no further than our on-demand production service! We'll help you get your project off the ground quickly and easily, with our assurance that your product will be produced to the highest standards.

Metal Injection Molding Production Capabilities

Neway Quality Control

Effective quality assurance helps to ensure that products or services are produced consistently, meet customer expectations, and comply with regulations and standards. It can also help to identify areas for improvement and increase customer satisfaction.

IS09001:2015 Certified Factory

Our factory holds an ISO 9001:2015 certificate – a testament to our dedication to quality.

Strict Manufacturing Standard

The facility complies with established manufacturing standards, like DIN-2768-fine and DIN-2768-medium.

Well-vetted Suppliers

Close partnerships with thousands of reliable material suppliers guarantee constant access to quality materials.

Advanced Testing Facilities

Completed prototypes go through various testing machines, like profile projectors, CMM, and 3D scanners.

Rigorous Quality System

Our strict commitment to quality control regulations ensures consistent quality is maintained throughout production.

Complete Quality Report

Get comprehensive quality reports from our in-house quality team or third-party labs.

Explore Related Resources

Solutions

Copyright © 2025 Neway Precision Works Ltd.All Rights Reserved.