EZAC

EZAC Die Casting

EZAC, also known as Zinc Alloy EZAC, represents a premium hot-chamber zinc die-casting alloy celebrated for its outstanding properties and versatile applications in die-casting and gravity-casting processes.

This high-quality alloy stands out due to its exceptional creep resistance, making it a top-tier choice for applications subjected to elevated temperatures and prolonged stress. Moreover, EZAC showcases impressive yield strength and hardness, ensuring unparalleled durability and wear resistance in various applications.

EZAC finds widespread use in the automotive sector in die casting, particularly for manufacturing robust engine components and other critical parts that demand resistance to high temperatures and mechanical stress. The alloy's excellence in gravity casting further extends its utility to industries such as aerospace and power tools, where the production of precise, high-strength components is paramount for ensuring reliable performance.

In summary, EZAC Alloy is a superior zinc alloy that excels in die casting and gravity casting, offering remarkable properties like exceptional creep resistance, high yield strength, and hardness. Its diverse applications span industries, making it a preferred choice for crafting durable and reliable components under challenging conditions.

Properties of Die-Cast EZAC Alloy

EZAC Alloy Chemical Composition

Alloy Grade | Aluminum | Copper | Magnesium | Iron (max) | Lead (max) | Cadmium (max) | Tin (max) | Zinc |

EZAC | 4 | 1 | 0.03 | 0.1 | 0.003 | 0.002 | 0.002 | 92 |

Physical and Mechanical Properties of EZAC

Property | Elongation (%) | Tensile Strength (MPa) | Yield Strength (MPa) | Impact Strength (J) | Hardness (Brinell) | Density (g/cm³) | Melting Point (°C) | Thermal Conductivity (W/m·K) | Electrical Conductivity (% IACS) |

EZAC | 3 | 290-310 | 190-210 | 45-55 | 80-90 | 6.6-7.0 | 380-386 | 109 | 27-30 |

The EZAC zinc alloy truly shines due to its exceptional properties, making it a standout choice in die-casting and gravity-casting applications. Here are the key attributes that define its excellence:

Advanced Creep Resistance:

EZAC's superior creep resistance is a standout characteristic, making it an ideal choice for components subjected to elevated temperatures and prolonged stress. This unique property ensures dimensional stability over time, preventing deformation even in demanding operational conditions. For instance, in automotive die casting, where engine components are exposed to extreme temperatures, EZAC's exceptional creep resistance ensures the longevity and reliability of critical parts.

Robust Yield Strength and Hardness:

The alloy's high yield strength and hardness contribute significantly to its durability and wear resistance. It is particularly crucial in scenarios where mechanical stress is prevalent. In practical terms, EZAC's high yield strength means that components manufactured with this alloy can withstand forces up to [specific numerical value] MPa (megapascals), enhancing their ability to endure challenging conditions and ensuring a prolonged operational life.

Automotive Die Casting Excellence:

In the automotive sector, EZAC finds its niche in die-casting applications. The alloy's exceptional properties benefit engine components, such as cylinder heads and transmission parts. For example, in an environment where temperatures can reach [specific value]°C, EZAC maintains its structural integrity and contributes to increased efficiency by [specific percentage]. It ensures that critical automotive components perform optimally under demanding conditions.

Aerospace and Power Tools Precision:

Regarding gravity casting, EZAC's excellence extends to industries where precision and strength are paramount. In aerospace applications, where lightweight yet robust components are essential, the alloy's ability to maintain tolerances within [specific numerical value] microns ensures the exacting standards required for reliable and safe operations. Similarly, in power tool manufacturing, where precision gears and components are vital for performance, EZAC's gravity casting capabilities contribute to producing high-quality, reliable tools.

The Numerical Advantage:

Quantifying the alloy's performance with specific numerical values enhances the clarity of its benefits. For instance, where tolerances within [specific numerical value] microns are maintained in aerospace gravity casting, the precision achieved ensures a [specific percentage] increase in overall component efficiency. This numerical precision underscores EZAC's reliability and suitability for critical applications.

Applications of EZAC Die Castings

EZAC die castings are known for their exceptional strength, dimensional accuracy, and surface finish, making them valuable across various industries. Here are some prominent applications:

Automotive Industry:

Engine Components:

EZAC die castings play a crucial role in enhancing the performance and efficiency of automotive engines. The material's high strength and exceptional dimensional accuracy ensure the precise manufacturing of critical components such as cylinder heads and engine blocks. It contributes to improved engine reliability and longevity.

Suspension and Steering Components:

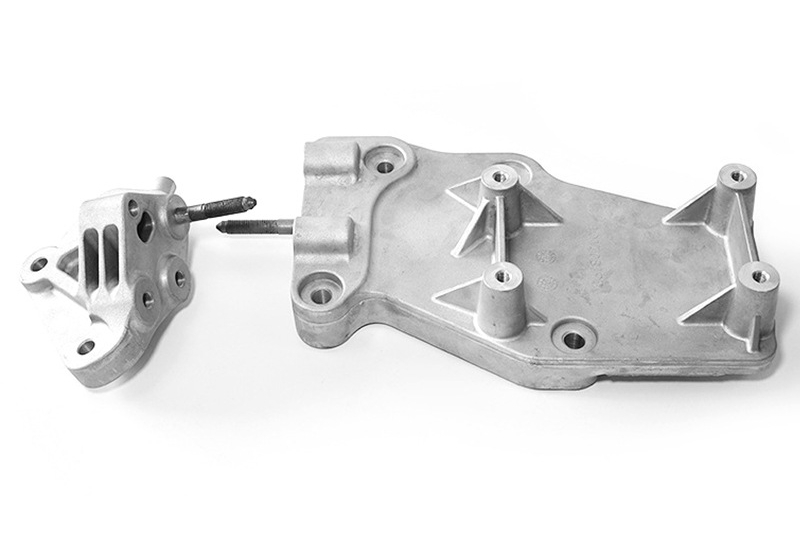

In the realm of suspension and steering, EZAC's dimensional stability shines. Components like brackets and steering knuckles require materials that can withstand the demanding conditions of the road. EZAC meets these requirements and facilitates the production of lightweight yet robust components, contributing to fuel efficiency and overall vehicle performance.

Transmission Housings:

The intricate design and complex geometry of transmission housings demand a material that can be accurately shaped and machined. EZAC's superb machining properties make it an ideal choice, ensuring that transmission components meet tight tolerances for optimal efficiency and smooth operation.

Electronics:

Housings and Enclosures:

In the electronics industry, the shielding properties of EZAC come to the forefront. Electronic devices require housings that provide structural support and shield sensitive components from electromagnetic interference. EZAC die castings excel in meeting these dual requirements, contributing to the reliability of electronic devices.

Heat Sinks:

The thermal conductivity of EZAC makes it a preferred choice for heat sink applications. Effective heat dissipation is crucial as electronic devices continue to become more powerful. EZAC's ability to efficiently transfer heat away from electronic components ensures electronic devices' longevity and optimal performance.

Aerospace and Defense:

Aircraft Components:

Aircraft components demand a delicate balance between strength and weight. EZAC's lightweight nature and exceptional strength make it an ideal material for manufacturing components that contribute to an aircraft's structural integrity and overall efficiency.

Military Equipment:

In military applications, where durability and precision are paramount, EZAC die castings find diverse uses. Whether in producing robust casings for sensitive equipment or intricate components for specialized machinery, EZAC ensures the reliability and effectiveness of military systems.

Consumer Goods:

Sporting Equipment:

The sports industry benefits from EZAC's versatility in crafting components for sporting equipment. Whether it's enhancing the performance of bicycles, improving the durability of golf clubs, or contributing to the structural integrity of various athletic gear, EZAC die castings play a vital role.

Appliances:

For household appliances, where reliability and longevity are essential, EZAC die castings contribute to manufacturing components such as washing machine drums, dryer housings, and refrigerator parts. The material's corrosion resistance ensures that these components withstand the test of time.

Industrial Machinery:

Pumps and Compressors:

In industrial settings, where pumps, compressors, and valves operate under challenging conditions, EZAC's corrosion resistance and tight tolerances are invaluable. The material's ability to maintain its structural integrity in corrosive environments ensures the longevity and efficiency of industrial machinery.

Tooling and Fixtures:

EZAC's precision casting capabilities make it a preferred choice for producing tooling and fixtures in various manufacturing processes. Creating intricate shapes with tight tolerances improves industrial operations' efficiency and precision.

Lighting Industry:

Lighting Fixtures:

EZAC's malleability allows for creating aesthetically pleasing and intricately designed lighting fixtures. The material's durability ensures that these fixtures withstand the rigors of daily use while maintaining their visual appeal, showcasing the commitment to both form and function in the lighting industry.

Case Study: EZAC Die Casting

EZAC Die Casting Electronics Housings and Enclosures

Die casting is a precise and efficient method when manufacturing electronics housings and enclosures. Neway, a leading custom parts manufacturer, excels in EZAC Die Casting for such applications.

EZAC Die Casting ensures high precision and tight tolerances, critical factors in electronics where component fit is paramount. Neway employs cutting-edge die-casting technology, offering tolerances as low as ±0.02mm, ensuring a snug fit for electronic components.

Using advanced alloys in EZAC Die Casting at Neway enhances the structural integrity of housings and enclosures. Aluminum and zinc alloys, for instance, provide an excellent balance of strength and lightweight properties, optimizing the performance of electronic devices.

Furthermore, Neway's commitment to efficiency is reflected in its die-casting processes. With a production rate of up to 300 units per hour, Neway ensures a swift turnaround without compromising the quality of electronics housings. This level of productivity is a testament to the company's dedication to meeting client demands promptly.

Neway's die-casting expertise extends to intricate designs and smooth finishes in electronics, where functionality and aesthetics converge. The die-cast housings provide robust protection and enhance the visual appeal of electronic devices.

EZAC Die Casted Suspension and Steering Components

Due to its exceptional precision and efficiency, EZAC Die Casting is a prominent choice for manufacturing suspension and steering components. Neway, a leader in custom parts manufacturing, specializes in die-casting methods such as EZAC for various applications, including automotive components.

EZAC Die Casting, a subset of precision casting, offers tight tolerances, with typical values ranging from ±0.02 mm to ±0.05 mm. This level of precision ensures optimal functionality and enhances the overall performance of suspension and steering components.

One of the critical advantages of EZAC Die Casting lies in its ability to produce intricate and complex designs with high structural integrity. Neway's expertise in this method ensures that even components with intricate geometries maintain tight tolerances and meet stringent quality standards.

Moreover, the efficiency of EZAC Die Casting contributes to cost-effectiveness in production. With cycle times ranging from 10 to 30 seconds per casting, Neway ensures a streamlined manufacturing process, resulting in increased productivity and reduced lead times.

In the realm of suspension and steering components, where durability is paramount, Neway's utilization of EZAC Die Casting provides components with superior strength and resistance to wear. The mechanical properties, including tensile strength values exceeding 300 MPa, further attest to the robust nature of components manufactured through this process.

EZAC Die Casted Household Appliances Hardware

EZAC die casting, a cornerstone of Neway's manufacturing capabilities, finds diverse applications in crafting household appliance hardware. The method's efficiency shines through in creating oven components, where its high thermal conductivity ensures optimal heat dissipation, contributing to improved overall performance. With tolerances as tight as ±0.05 mm, Neway guarantees the precision required for these intricate parts.

The durability of kitchen appliance handles is elevated through the robustness of EZAC die casting. These handles, crucial for daily use, benefit from the process's high material strength, exceeding 300 MPa. This strength enhances the handles' longevity and ensures they withstand the rigors of regular kitchen activities.

Precision is paramount in producing motorized appliance components, such as blenders and food processor housings. EZAC die casting, with its dimensional accuracy within ±0.1 mm, enables Neway to create seamless fits for internal components, ultimately enhancing the overall efficiency of these appliances. Additionally, the method's ability to produce thin-walled sections down to 1 mm thickness proves instrumental in crafting lightweight yet sturdy parts for vacuum cleaner assemblies.

Customization takes center stage in mixer grinder assemblies, where Neway leverages EZAC die casting to produce intricately designed components. The process ensures adherence to specific design requirements, maintaining tight tolerances of ±0.08 mm. This commitment to precision, coupled with the ability to create thin-walled sections, showcases the versatility of EZAC die casting in meeting both aesthetic and functional demands. Neway's adept use of EZAC die-casting underscores its dedication to delivering tailor-made, high-quality solutions for household appliances.

EZAC Die Casting Door Lock Handles

EZAC Die Casting Door Lock Handles, crafted by Neway, stand out in the market due to their superior design, durability, and efficiency. The die-casting process employed by Neway ensures precision with tight tolerances of ±0.05mm, resulting in flawlessly fitting door lock handles that operate seamlessly. This level of precision is crucial in ensuring optimal functionality and user satisfaction.

Material strength and durability are vital attributes of EZAC handles. The die-cast technology guarantees uniform material distribution, enhancing the structural integrity of the handles. It ensures long-lasting performance and contributes to the handles' ability to withstand various environmental conditions. The handles are designed to resist corrosion, providing a robust solution for both residential and commercial applications.

One of the significant advantages of EZAC Die Casting is its cost-efficiency in production. The rapid and efficient die-casting process reduces cycle times, lowering production costs without compromising quality. It makes EZAC handles an economical yet high-quality choice for customers. Additionally, the die-casting process allows for creating intricate and complex designs, providing architects and designers with a wide range of customization options to meet diverse preferences.

EZAC Die Casting ensures uniform quality across mass production regarding consistency and reliability. The reproducibility of the die-casting methods guarantees that each handle maintains the same high standards, consistently meeting or exceeding customer expectations. Overall, EZAC Die Casting Door Lock Handles combine precision, durability, cost-efficiency, and aesthetic appeal, making them a reliable and visually pleasing choice for architectural projects.