20 Defects of the Metal Stamping Process

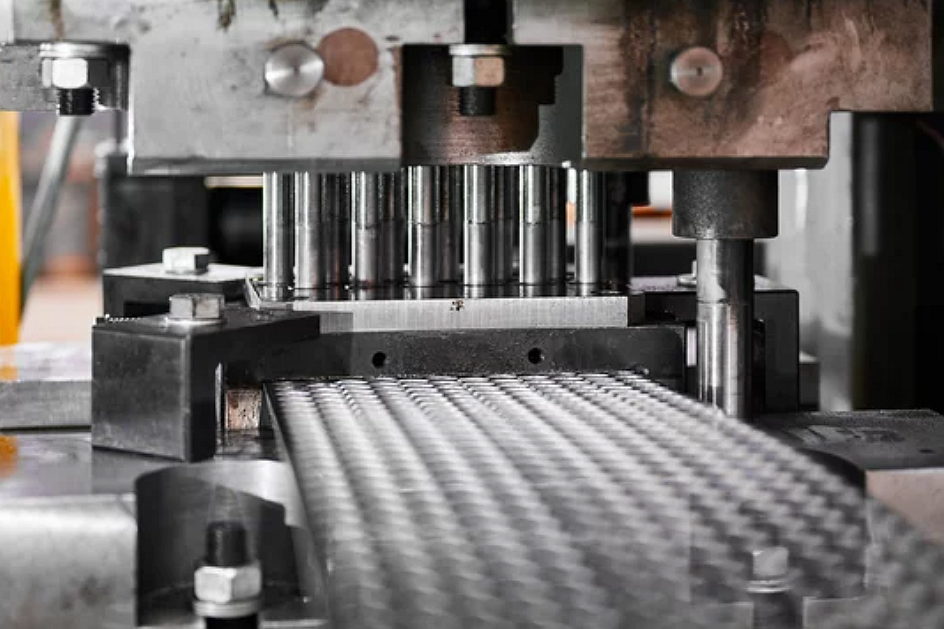

Metal stamping is a complex manufacturing process with many variables that can lead to defects if not adequately controlled. Understanding common stamping flaws allows prevention and correction. Typical metal stamping defects include:

Burrs

Sharp raised edges or rolls of excess metal along stamping edges caused by the clearance between punch and die. Deburring secondary operations are required. Prevent by precision grinding punches/dies for clearance control.

Roll-over or Die Roll

It distorted arc shape along stamping edges from misalignment between upper and lower tooling. The cause is worn guides, loose bolts, or damaged die sets. Avoid inspecting and maintaining tooling.

Part Fracture

Complete cracking or tearing during stamping from excessive tonnage, worn tooling, or improper metal properties. Ensure rated tonnage is not exceeded, and material meets requirements.

Scrap Web

Excess metal remnants between parts along shear edges from worn, chipped, or poorly aligned die. Realign, sharpen, or replace tooling. Enlarge punch-to-die clearance.

Bursting

It is ruptured or torn surfaces around stamped holes or inside profiles from worn punches, improper clearance, or dull die-opening corners. Resharpen or replace worn tooling.

Springback

Partially released stresses cause stamped forms to spring back slightly after removal. Manage by over-bending and applying bend compensation.

Twisting

Uneven stress distribution causes stamped parts to twist slightly and lose flatness. The cause is temperature variations or non-parallel upper and lower dies.

Bowed profile

Stamped strip or flat length is not straight but slightly bowed or arched—results from uneven holding pressure, worn guides, or strip positioning.

Cracks

Hairline cracks or tear fractures along formed walls bends, or deep draws. Reduce draw depth and radii. Increase tonnage and lubrication. Consider annealing.

Galling and Scratching

Transfer of material between the die and part leaves galled areas or scratches. Apply proper lubrication; avoid localized high stresses.

Wrinkling

Metal surface deforms with ripples or wrinkles around formed areas. Reduce forming radius or depth. Check the material thickness and properties. Consider annealing.

Smearing

Metal flows unevenly in an uncontrolled manner outside the form profile, causing distortion. Lower tonnage applications and less lubrication may help.

Splitting

Sheet separates along grain boundaries or crystal planes under stress during forming. Avoid modifying orientation relative to the grain direction.

Incomplete Filling

Metal does not fill the die impression leaving voids or short forms. Increase tonnage or dwell time. Check lubrication. It may require redesign.

Sink Marks

The deformed area around stamped bosses, often with surface dimples. Increase material thickness or radius. Annealing can help thicker materials.

Flash

Excess metal extrudes beyond the trim line along the die gap, causing burrs or deformation. Reduce clearance, sharpen punch, and dies. Adjust tonnage.

Staining

Discolored patches appear on the surface from a chemical reaction with lubricant. Try different lubricants. Clean dies thoroughly between runs.

Inconsistent Dimensions

Variation in critical dimensions between stamped parts. Maintain press settings. Monitor and control metal properties, lubrication, and production rates.

Improperly Formed Holes

Off-center, oblong, or ragged stamped holes from worn or chipped punches and dies. Resharpen or replace tooling.

Part Shift

Punch contacts part off-center, causing distortion. Realign guides and stops. Check the feed system. Replace worn tooling.

Misaligned Features

Formed holes or cutouts fail to properly align between operations due to loose components or worn guides in progressive dies.

Effective process monitoring, control, and maintenance are crucial to minimizing stamping defects. Upfront communication between product engineers and fabricators allows proper design and tooling selection.

Neway Stamping Reputation

When AeroTech needed a partner to precision stamp aluminum parts with minimal distortion, they chose Neway. Over one year, Neway produced over 250,000 lightning holes and cutouts with position-to-position tolerance of just +/-0.005 inches. Their engineering collaboration was invaluable for manufacturability. And Neway's finishing department delivered parts ready for immediate assembly, reducing AeroTech's costs by 35%.