What Are the Most Widely Used Rapid Prototyping Services?

Rapid prototyping refers to technologies that allow physical prototypes to be quickly created from digital data. Rapid prototyping can reduce development costs and time to market for new products by enabling faster design iteration. There are several rapid prototyping services in wide use today.

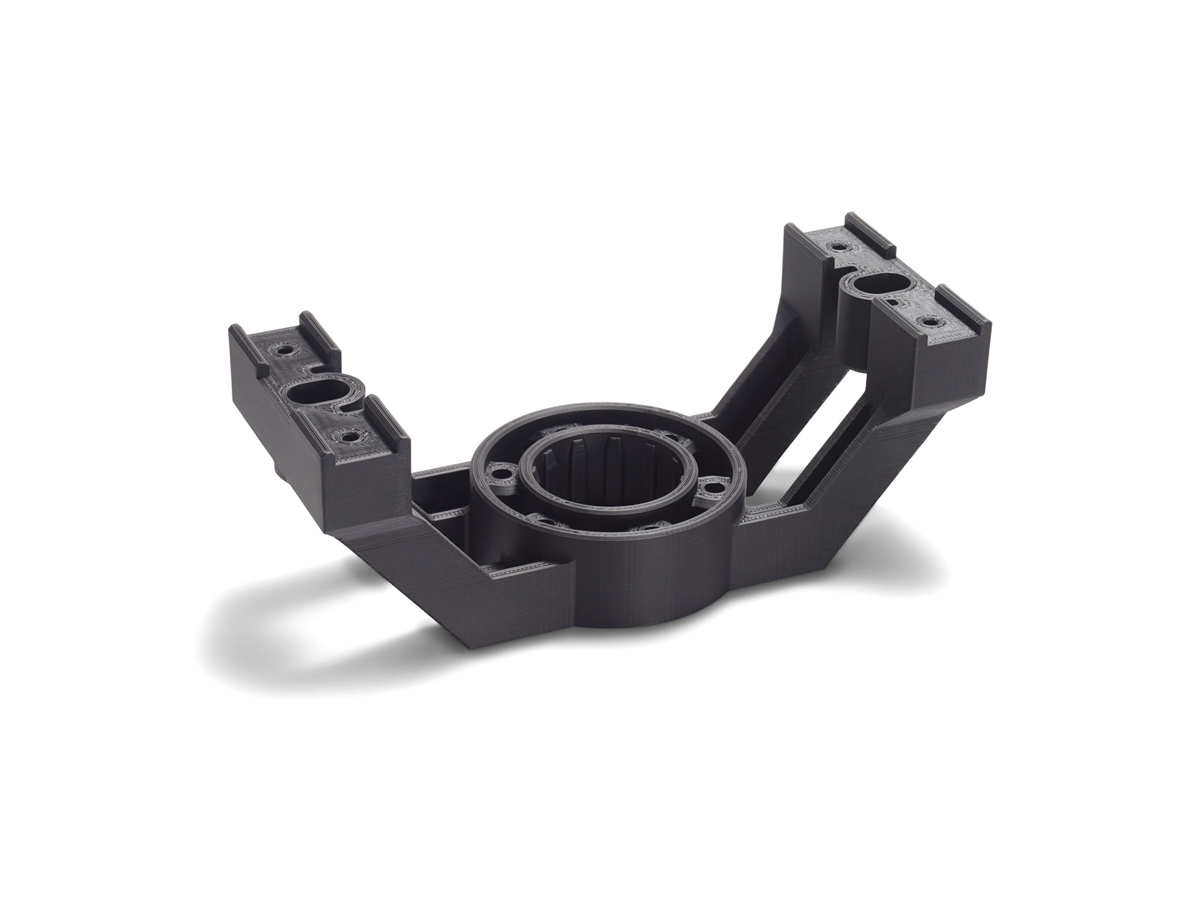

3D Printing

One of the most popular rapid prototyping techniques is the 3D printing service. 3D printing builds up successive layers of material, usually plastics or resins, to create a three-dimensional object from a digital model. Various 3D printing processes exist, but fused deposition modeling (FDM) and stereolithography (SLA) are the most common.

FDM printers work by heating and extruding thermoplastic filament in layers based on a CAD model. FDM offers reasonably fast print speeds, affordable desktop models from companies like MakerBot and Ultimaker, and a range of material choices, including ABS, PLA, PETG, and flexible filaments. Resolution is limited by nozzle size, layer height, and x/y axis steps, with 0.1mm to 0.3mm being typical.

SLA uses an ultraviolet laser to selectively cure liquid resin layer by layer until the object is complete. Models from Formlabs and others provide higher resolution than FDM, down to 0.025mm or less. SLA resins can mimic the properties of plastic, rubber, or ceramic. However, print speed could be faster, and materials are more limited than FDM.

3D printing services like Sculpteo, Shapeways, and Protolabs offer online ordering of 3D prints directly from CAD files. Lead times range from days to weeks, depending on materials and finishing. For prototyping, SLA and SLS prints from nylon offer a good surface finish. Metal options like DMLS are also available.

CNC Machining

Computer numerical control (CNC) machining prototyping service is a subtractive process using power tools like mills and lathes to cut material blocks into shapes specified by CAD models. CNC machining is valued for functional testing because prototypes can be fabricated from production-intent metals. Typical tolerances range from 0.005" to 0.020" (0.13mm - 0.5mm).

In one to two weeks, online services from Fictiv, Protolabs, and Xometry provide CNC machined parts from metals like aluminum and steel. More expensive expedited turnaround times as fast as one day is available. Due to setup time and cost considerations, CNC machining is best for smaller parts.

Rapid Molding

For simulating the properties of production plastic parts, rapid molding prototyping services offer high fidelity. The process uses composite material molds to form high-pressure thermoplastic resins, producing complex, high-tolerance parts. Lead time for prototype molds ranges from days to 2 weeks. Cost is also low but only suited for low-volume production.

Low-volume injection molding runs can be ordered from services like Protolabs, Neway Precision, and Xometry. Typical minimum orders are in the hundreds of parts. For accurate functional prototyping at lower volumes, Neway 3D-printed molds, with about one week lead times, produce 10-100 injection molded parts.

Sheet Metal Fabrication

Sheet metal is commonly used across industries, from consumer electronics to medical devices. Rapid sheet metal fabrication services help verify new product manufacturing methods and material performance. Services like Fictiv and Xometry provide quick-turn sheet metal laser or CNC cutting based on CAD files, with one to two-week lead times typical.

Bending and welding can produce more complex sheet metal assemblies. Tolerances of +/- 0.005" (0.13mm) are standard. Aluminum and steel are commonly used metals, but more exotic alloys are also available. Low minimums of 1-10 units make this process suitable for early-stage prototyping.

Urethane Casting

Urethane casting produces durable prototypes from silicone rubber molds for replicating plastic parts in low volumes. The liquid urethane resin can mimic the properties of materials like ABS, polypropylene, epoxy, and acrylic. The typical turnaround time is about one to two weeks.

Neway and other suppliers offer urethane casting services and custom manufacturing. 3D-printed parts are often used to create the initial silicone mold master. Cast urethane is famous for the functional testing of plastic components and ergonomic studies requiring multiple iterations.

Rapid Tooling

For prototyping larger production runs, "rapid tooling" techniques build molds quickly through 3D printing or CNC machining. It allows injection molding, thermoforming, or other manufacturing processes using tools derived from CAD data. Rapid tooling with 3D printed molds offers mid-sized production runs from 10-100+ parts. Complex tooling with CNC machined mold cavities can accommodate larger production volumes.

Rapid tooling can simulate end-use parts' appearance, feel, and functionality. Companies like Protolabs, Stratasys Direct, and Xometry offer rapid tooling in concert with their other rapid prototyping services to provide a complete solution. Typical lead times range from days to weeks.

Choosing a Rapid Prototyping Service

With today's range of rapid prototyping processes, selecting the optimal service involves weighing factors like required turnaround time, order volumes, choice of materials, accuracy, surface finish, and cost. Here are some key considerations when choosing a rapid prototyping provider:

Processes strength - Look for services offering a range of processes like 3D printing, CNC machining, and injection molding for maximum flexibility.

Part size and materials - Make sure a service can accommodate your needs for part dimensions, production volumes, and material types.

Accuracy and tolerances - More expensive processes like CNC machining and metal 3D printing offer tighter tolerances for functional testing.

Turnaround time - Overnight and expedited services are available for urgent projects at a premium cost.

Design file formats - Services should support common CAD and 3D file types like STEP, IGES, and OBJ. Some offer online file checking.

Secondary services - Look for finishing options like dyeing, painting, and plating to simulate production parts. Some offer design for manufacturing analysis.

Customer service - Choose services with solid customer support and project management capabilities. Read reviews carefully.

Cost - Compare service prices and minimum order quantities to find the best value. Simple parts in low volumes are the most economical.

Production capabilities - Some services provide an easy transition from prototyping to production tooling to reduce time-to-market.

The range of accessible online services available today makes finding the right rapid prototyping solution more accessible than ever. Leveraging rapid prototyping allows product developers and engineers to quickly explore design concepts and refine functionality while reducing development risk. With many processes and providers to choose from, companies can find the ideal service to meet their specific prototyping needs and accelerate innovation.

Neway Rapid Molding Service

"I've used several rapid prototyping services, but none match the quality and speed of Neway's rapid molding. Their composite molds produce precise, functional prototypes in just days, perfect for testing designs and concepts. Plus, their team is incredibly responsive and helpful throughout the whole process. Neway is my top recommendation if you're looking for an affordable, expedited injection molding solution." By Alfred Melson - Good design product development manager (HT&M Group)