What Are the Differences Between Die Casting and Investment Casting

Comparison Between Die Casting and Investment Casting

Die casting and investment casting are popular manufacturing methods for creating complex metal parts. Each process has advantages and disadvantages, making them suitable for different applications and production scenarios.

Materials and Design Capabilities

The most significant difference between die casting and investment casting is in the range of alloys used. Die casting is limited to non-ferrous metals like aluminum, zinc, magnesium, and copper alloys. Investment casting can produce components in almost any metal alloy, including steel, nickel, titanium, aluminum, and super alloys.

Die casting can produce intricate geometries with excellent dimensional accuracy, thin walls, and low porosity. Multi-slide die casting enables complex internal features and undercuts. Investment casting is better suited for simpler, external-feature-heavy designs. Skinny sections and extreme intricacy are challenging to achieve.

Production Rates and Scalability

Die Casting:

Die casting is a high-volume production process suitable for large-scale manufacturing. It is a highly automated process that can produce parts rapidly, making it cost-effective for high quantities. However, setting up the die-casting tooling can take time and effort, making it less viable for small production runs. Die casting offers exceptionally high production rates, capable of producing thousands of castings per hour. It is the fastest method for metal casting in high volumes. Investment casting production is much slower, typically producing 50-100 castings per hour.

Investment Casting

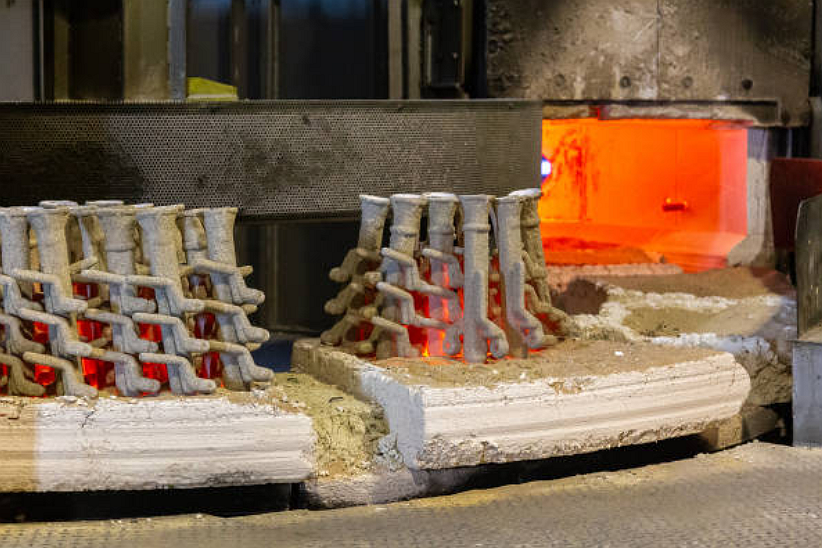

Investment casting is generally more time-consuming than die casting and better suited for lower to medium production volumes. The process involves creating a wax pattern, building a ceramic shell around it, melting the wax, and then pouring molten metal into the shell. While it may not match the high production rates of die casting, investment casting offers the advantage of producing intricate and complex parts in smaller quantities. However, investment casting can match die casting's economies of scale. For example, investment casting a run of 10,000 castings takes the same labor and overhead as a run of 100,000. The costs are amortized over larger production volumes.

Surface Finish and Dimensional Accuracy

Die Casting:

Die casting typically results in a good surface finish and high dimensional accuracy. The metal molds used in die casting ensure consistent part dimensions, making it ideal for applications where tight tolerances are critical. Die-cast parts have excellent dimensional accuracy and stability if the die is designed correctly. Tolerances down to 0.005 inches are possible. The as-cast surface finish can be Ra 3.2 μm (125 μin) or better. Minimal finishing/machining is required.

Investment Casting

Investment casting can produce parts with excellent surface finish and exceptional dimensional accuracy. The ceramic molds allow for smooth and detailed surfaces, making them suitable for parts that require a high level of aesthetics and precision. Investment cast surfaces are coarser, around Ra 6.3 μm (250 μin), but can be improved to 1.6 μm (63 μin) with shot peening. Dimensional accuracy is looser than die casting, around 2% of the nominal value. Additional finishing work is often required.

Tooling and Setup Costs

Die Casting

The tooling and setup costs for die casting can be substantial. Creating metal molds (dies) for die casting can be expensive and time-consuming. However, these costs can be justified for large production runs where the cost per unit decreases significantly. Die casting requires expensive steel tooling that withstands high pressures and lasts tens to hundreds of thousands of cycles. A medium-sized die set can cost $5,000 - $20,000. More significantly, complex dies are over $100,000.

Investment Casting

While investment casting involves tooling costs, they are generally lower than die casting. The initial investment is relatively affordable, which makes it a preferred choice for prototyping and small production batches. Investment casting molds are disposable and made from cheaper materials like wax, ceramics, and refractory cement. Tooling costs range from $1,000 for a simple wax pattern to $30,000 for a complex multi-piece ceramic mold. Re-tooling costs are lower.

Applications of each casting method

Die casting applications

Die casting produces high-volume components with thinner walls, tighter tolerances, and more intricate geometries. Typical applications include automotive parts like intake manifolds, engine blocks, chassis components, gears, and transmission cases. Consumer products like appliances, electronics, toys, and furniture hardware also utilize die-cast parts extensively.

Investment casting applications

Investment casting is ideal for lower-volume complex castings using alloys that cannot be die-cast. Aerospace and industrial gas turbine components, artificial joints, dental implants, jewelry, cutlery, and weapon components commonly use investment casting. It's also used to cast parts that require controlled material properties or will undergo additional hot or cold working after casting.

Selection Criteria

A. Volume of Production:

Choose die casting for high-volume production runs where the initial tooling costs can be distributed across many parts. Opt for investment casting when dealing with smaller production volumes or for prototyping and low-volume batches. Die casting is advantageous for production volumes of over 20,000 units per year. Below 5,000 units, investment casting is likely the better option based on lower tooling costs. In the 5,000-20,000 range, both processes should be evaluated.

B. The complexity of the Design:

If your design requires intricate features, thin walls, and complex geometries, investment casting offers greater design freedom and better suits such applications. Intricate parts with thin, enclosed internal features and tight tolerances lend themselves to die casting. Simple, open shapes like brackets, fittings, and rings are better suited for investment casting.

C. Material Requirements:

Consider the material properties needed for your parts. Die casting is ideal for non-ferrous metals, while investment casting accommodates non-ferrous and ferrous metals. If aluminum, zinc, or magnesium alloys meet the needs, die casting offers the fastest production of intricate shapes. Investment casting is the better process for steels, titanium, or superalloys.

D. Budget Considerations:

If you have a limited budget or need to produce smaller quantities, investment casting might be more cost-effective due to its lower tooling costs. Die casting requires higher initial tooling costs but lower per-part costs at high volumes. Investment casting offers lower startup costs but higher per-part costs in production. For short production runs, investment casting is generally more economical.

E. Lead Time and Time-to-Market:

Die casting can offer shorter production lead times for high volumes, while investment casting might take longer, allowing for faster prototyping and development of complex parts. Die-casting tools take 9-12 weeks to manufacture. Investment casting molds take 1-3 weeks. This faster lead time allows investment casting to get products to market quicker.

Try Neway with 20% Off Your Oder

With three decades of expertise, Neway provides die casting, investment casting, sand casting, injection molding of metal, plastic, and ceramics, sheet metal fabrication, and rapid prototyping. Supported by advanced equipment and rigorous quality control, we offer intricate castings, precision injection molds, and expert CNC machining. New customers receive 20% off their first order, so you can evaluate our capabilities risk-free.