Cast Iron

Cast Iron (Gray and Ductile) Precision Casting Manufacturing

Cast iron is often used in sand casting, and its materials are divided into gray cast iron and ductile iron. With exceptional damping capacity, Gray iron sand castings suit power tools and machinery, attenuating vibrations. It's easily machinable and cost-effective for gear manufacturing and engine components. On the other hand, ductile iron sand castings, boasting high tensile strength, find their place in automotive and aerospace components where load-bearing is critical. Its flexibility enhances toughness, which is vital in safety-critical parts.

What Is Cast Iron (Gray and Ductile)?

Gray iron is a type of cast iron known for its gray color when fractured. It is made by melting pig iron and adding scrap iron, steel, graphite, and other alloying elements. The critical feature of gray iron sand castings is their excellent damping capacity, which means they can absorb and dissipate vibrations, making them suitable for components in machinery and power tools. It is also readily machinable, making it cost-effective for parts that require precision machining.

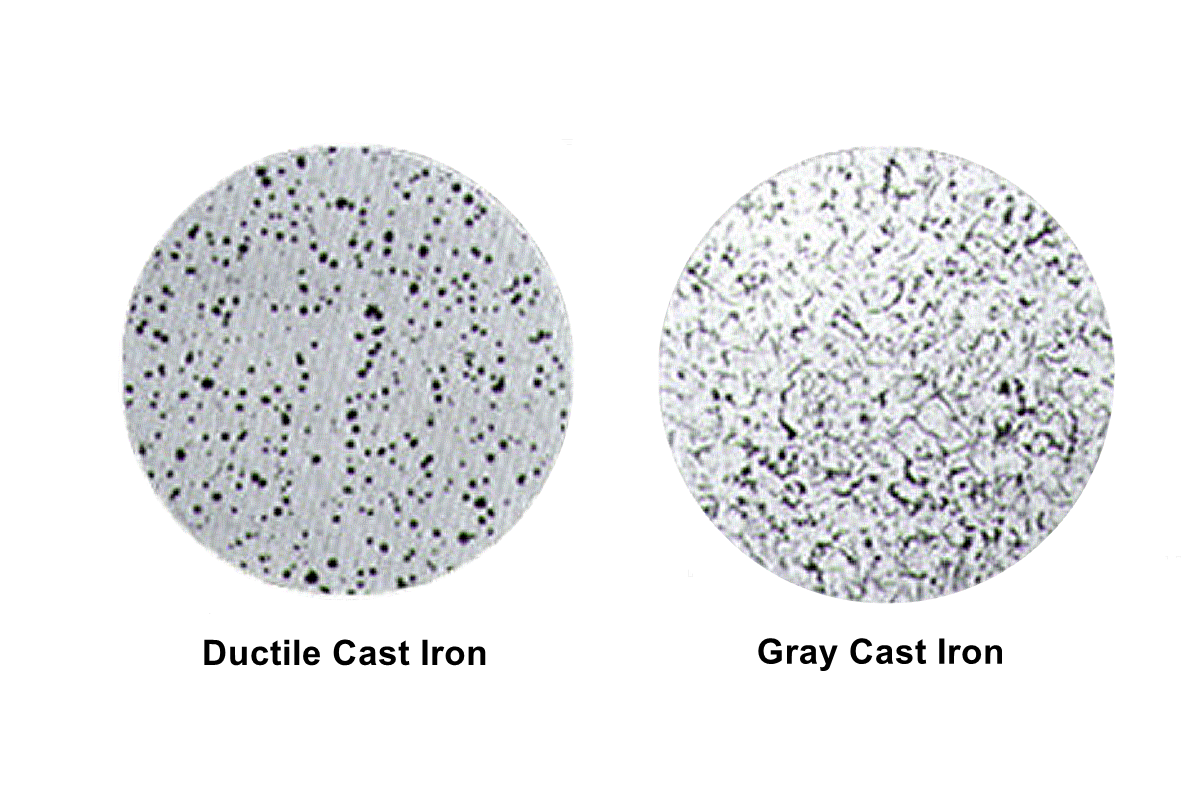

Ductile iron, or nodular or spheroidal graphite iron, is another form of cast iron. It is created by adding small amounts of magnesium or cerium to molten iron before casting. Ductile iron sand castings are characterized by high tensile strength and good ductility, meaning they can deform without breaking. It makes it valuable in applications where components must withstand significant loads, such as automotive and aerospace industries.

Properties of Cast Iron (Gray and Ductile)

Chemical Comparison of Cast Iron (Gray and Ductile)

Chemical Component | Carbon (C) | Silicon (Si) | Manganese (Mn) | Phosphorus (P) | Sulfur (S) | Magnesium (Mg) | Copper (Cu) | Nickel (Ni) | Chromium (Cr) | Other Alloying Elements |

|---|---|---|---|---|---|---|---|---|---|---|

Cast Iron Gray | 2.7% - 3.8% | 1.0% - 3.0% | 0.5% - 1.5% | 0.07% maximum | 0.12% maximum | Not typically added | Not typically added | Not typically added | Not typically added | May include small amounts |

Cast Iron Ductile | 3.2% - 4.0% | 1.8% - 2.8% | 0.15% - 0.40% | 0.03% maximum | 0.03% maximum | 0.04% - 0.06% | 0.20% maximum | 0.03% maximum | 0.02% maximum | May include small amounts |

Function of Chemical Components

Carbon (C):

Cast Iron Gray: Carbon content in Cast Iron Gray typically ranges from 2.7% to 3.8%. Carbon plays a crucial role in enhancing hardness and strength. Higher carbon levels increase the hardness of gray cast iron, but excessive carbon can lead to brittleness.

Cast Iron Ductile: Cast Iron Ductile contains a higher carbon content, ranging from 3.2% to 4.0%. The increased carbon content contributes to the formation of nodular graphite, improving flexibility and strength.

Silicon (Si):

Cast Iron Gray: Silicon content typically ranges from 1.0% to 3.0%. Silicon promotes the formation of graphite in gray cast iron, improving its machinability, fluidity, and resistance to thermal shock.

Cast Iron Ductile: Silicon content in Cast Iron Ductile falls within the range of 1.8% to 2.8%. Silicon aids in the formation of nodular graphite, enhancing flexibility and strength.

Manganese (Mn):

Cast Iron Gray: Manganese content usually ranges from 0.5% to 1.5%. Manganese enhances the hardenability of gray cast iron and helps control the size and distribution of graphite flakes.

Cast Iron Ductile: Cast Iron Ductile contains a lower amount of manganese, ranging from 0.15% to 0.40%. Manganese plays a role in promoting the formation of nodular graphite.

Phosphorus (P):

Cast Iron Gray: Phosphorus content is kept at a maximum of 0.07%. In small amounts, phosphorus can improve fluidity, but excessive phosphorus can make gray cast iron brittle.

Cast Iron Ductile: Phosphorus is minimized to a maximum of 0.03% in ductile iron for improved flexibility.

Sulfur (S):

Cast Iron Gray: Sulfur content is typically kept at a maximum of 0.12%. When excess, sulfur can lead to brittleness in gray cast iron.

Cast Iron Ductile: In ductile iron, sulfur is minimized to a maximum of 0.03% to improve flexibility and reduce the risk of brittleness.

Magnesium (Mg):

Cast Iron Gray: Magnesium is not typically added to gray cast iron.

Cast Iron Ductile: In Cast Iron Ductile, a small amount of magnesium, typically ranging from 0.04% to 0.06%, is added to promote the formation of nodular graphite, which significantly enhances flexibility and strength.

Physical and Mechanical Properties of Cast Iron

Gray Cast Iron and Ductile Cast Iron are two distinct materials with unique features in sand casting. Gray Cast Iron, renowned for its excellent castability, is characterized by its gray appearance due to the presence of graphite flakes. It offers good thermal conductivity and damping capacity, making it a top choice for applications in the consumer electronics and power tools industries. Its tensile strength, ranging from 20,000 to 60,000 psi, provides impressive wear resistance, making it suitable for components like engine blocks and brake discs.

Property | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (Brinell) | Shear Strength (MPa) | Impact Strength (J) | Fatigue Strength (MPa) | Thermal Conductivity (W/m·K) | Density (g/cm³) | Melting Range (°C) |

|---|---|---|---|---|---|---|---|---|---|

Gray Cast Iron | 414 | 276 | 440 | 345 | 7 | 160 | 65 | 7.8 | 1200 |

Ductile Cast Iron | 800 | 600 | 230 | 600 | 25 | 350 | 50 | 7.3 | 1350 |

Key Features and Applications of Cast Iron

On the other hand, Ductile Cast Iron, also known as nodular cast iron, stands out for its remarkable flexibility and strength. It features spherical graphite nodules within its microstructure, imparting superior tensile strength of around 60,000 to 100,000 psi. It makes Ductile Cast Iron ideal for demanding automotive and locking system applications. Its high precision, often exceeding ±0.001 inches, ensures that critical components such as gears and shafts maintain their structural integrity. Both materials have their merits, catering to diverse industry needs, but Ductile Cast Iron excels in applications requiring higher mechanical performance and precision.

Gray Cast Iron sand castings

Gray Cast Iron sand castings offer key features that make them indispensable in various industries. Notably, their excellent machinability and vibration-damping characteristics make them a popular choice for applications in consumer electronics and power tools. With a thermal conductivity that rivals most materials, Gray Cast Iron dissipates heat efficiently, making it ideal for components such as motor housings and machinery bases. Its wear resistance is another standout feature, ensuring longevity in demanding environments.

Gray Cast Iron finds its place in producing speaker enclosures in consumer electronics, providing superior acoustic properties. Furthermore, its exceptional corrosion resistance makes it an excellent candidate for outdoor lighting solutions. Whether in streetlight poles or intricate decorative fixtures, Gray Cast Iron sand castings have proven their mettle in various applications where durability and precision are paramount.

Ductile Cast Iron Sand Castings

Ductile Cast Iron sand castings offer unique features and excel in various industrial applications. Their exceptional elasticity and high tensile strength, typically ranging from 60,000 to 100,000 psi, set them apart. Ductile Cast Iron is preferred for components subjected to heavy loads and stresses, as seen in the automotive and locking system industries. Its microstructure, with spherical graphite nodules, enhances its toughness and ensures that it can withstand substantial mechanical forces, making it ideal for components like gears and shafts.

Furthermore, Ductile Cast Iron is prized for its precision, often reaching an impressive range of ±0.001 inches. This level of accuracy is precious in applications where tight tolerances are essential, such as within the telecommunication and lighting solutions sectors. In summary, Ductile Cast Iron's combination of strength, flexibility, and precision makes it a go-to material for demanding applications, ensuring the reliability and performance of critical components in various industries.

Considerations of Selection in Sand Casting

Regarding sand casting, understanding the differences between Ductile Cast Iron (DCI) and Gray Cast Iron (GCI) in terms of mechanical properties, versatility, machinability, surface finish, noise and vibration damping, and cost-effectiveness is crucial. Each material has its unique characteristics and advantages, and here, we'll delve into these factors, citing real-world examples from various industries, including Consumer Electronics, Telecommunication, Lighting Solutions, Power Tools, and Locking Systems.

Mechanical Properties and Strength:

DCI, also known as nodular cast iron, is characterized by its excellent tensile strength, ranging from 60,000 to 100,000 psi. The nodular graphite microstructure within DCI contributes to its remarkable ductility and toughness. This combination of strength and ductility is precious in applications where components must withstand high stresses and shocks. For instance, in the automotive industry, DCI is extensively used to manufacture engine blocks subjected to significant mechanical loads. The high tensile strength of DCI ensures that the engine blocks can endure these conditions without failure.

GCI, in contrast, excels in compressive strength, which can reach around 70,000 psi. Its microstructure primarily consists of graphite flakes, making it more brittle than DCI. GCI's compressive strength is ideal for applications where resistance to crushing or compression is crucial. An example is the production of locking system components like lock cylinders. These components must withstand compressive forces, and GCI's strength makes it a reliable choice for such applications.

Versatility in Casting:

DCI offers greater versatility in casting due to its excellent fluidity and mold-fill characteristics. It makes it well-suited for complex, intricate shapes and thin sections. Consumer electronics often demand intricate and compact designs, where DCI's versatility shines. Components like brackets and mounts within smartphones and laptops are often made from DCI because they can accurately reproduce intricate designs.

While more versatile than DCI, GCI is still suitable for applications requiring more superficial, straightforward shapes. For instance, in the telecommunication industry, GCI produces antenna bases, which typically have a less complex design than many consumer electronics components.

Machinability:

Machinability is an essential consideration for both DCI and GCI. DCI's higher hardness can lead to increased tool wear during machining. However, advancements in cutting tool materials, such as carbide inserts, have significantly improved DCI machining. It is essential in applications where precise machining is required. For example, DCI's machinability is essential in producing power tool components like gears and shafts to ensure the components meet tight tolerances and specifications.

GCI's graphite microstructure offers excellent self-lubricating properties, reducing tool wear during machining. It makes GCI particularly suitable for applications where cost-effective machining is a priority, such as in the production of lock components, where keyways and keyholes must be accurately machined.

Surface Finish:

DCI's superior fluidity during casting generally produces a smoother surface finish. It is especially advantageous in industries where aesthetics are a significant factor. Lighting solutions often require decorative and polished components. DCI is preferred for manufacturing lighting fixtures, ensuring a visually appealing surface finish that enhances the product's aesthetics.

GCI can produce a slightly rougher surface finish with its graphite structure than DCI. However, GCI's surface quality is more than adequate in applications where surface finish, such as power tool housings, is not critical.

Noise and Vibration Damping:

DCI's outstanding damping properties make it an excellent choice for applications where noise and vibration reduction are crucial. In the automotive industry, DCI is extensively used for engine blocks. Engine blocks made from DCI absorb and reduce engine vibrations, resulting in a quieter and more comfortable ride for passengers. The damping properties of DCI also contribute to increased engine longevity.

GCI also offers good damping capabilities, making it a valuable choice in applications where noise and vibrations must be minimized. For instance, GCI produces tool housings in the power tool industry, reducing noise and vibrations during prolonged tool use and enhancing user comfort and safety.

Cost-Effectiveness:

Cost-effectiveness is a critical factor in material selection. While DCI may have a slightly higher material cost than GCI, its advantages often lead to cost savings in the production process. Its excellent castability, reduced machining needs, and long-term durability make it a cost-effective choice. In the consumer electronics industry, for instance, the extended product life and reduced need for replacements due to DCI's durability make it a cost-effective option, especially for components that require high precision and durability.

GCI's cost-effectiveness is evident in applications that align with its specific strengths, such as lock cylinder production. The reduced machining requirements and its suitability for simpler shapes make it an economical option in these scenarios, where the focus is on producing reliable and cost-effective locking system components.

Precision Casting Cases Study

Neway is involved in many industries as an experienced precision castings (die castings, investment castings, gravity castings, and sand castings) manufacturer.

Here are related industries casting cases for your reference: