PPE-PS

PPE-PS (Polyphenylene Ether - Polystyrene) Injection Molding Manufacturing

Overview of Injection Molded PPE-PS

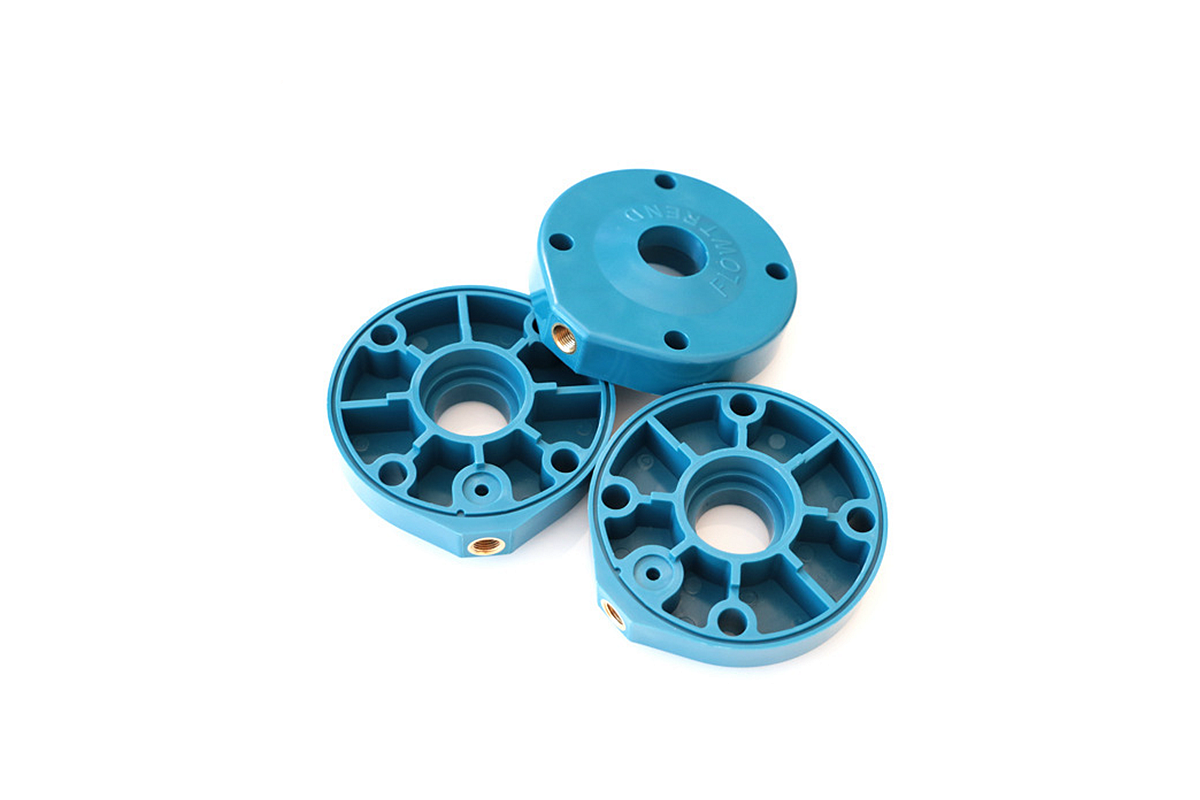

Injection-molded PPE-PS (Polyphenylene Ether - Polystyrene) comes in various grades, each tailored for specific applications. These grades vary in properties like heat resistance, impact strength, and electrical characteristics, ensuring suitability across automotive and electronics industries.

Neway utilizes several common grades of injection-molded PPE-PS:

General-Purpose PPE-PS

Flame-Retardant PPE-PS

High-Impact PPE-PS

Heat-Resistant PPE-PS

Electrical Insulation PPE-PS

Injection Molded PPE-PS Grades Comparison

Selecting the correct PPE-PS grade for injection molding depends on your application needs. Consider factors like required heat resistance, impact strength, electrical properties, and flame retardancy, matching them to the grade that best suits your part's functional requirements.

Key Features And Applications

PPE-PS Grade | Key Properties | Common Applications |

|---|---|---|

General-Purpose PPE-PS | - Good heat resistance - Chemical resistance - Dimensional stability | Automotive components, electrical housings, connectors |

Flame-Retardant PPE-PS | - Flame resistance - Low smoke emissions - Heat resistance | Electrical and electronics, aircraft interiors, HVAC |

High-Impact PPE-PS | - Excellent impact strength - High toughness - Dimensional stability | Automotive bumpers, medical devices, consumer goods |

Heat-Resistant PPE-PS | - Exceptional heat resistance - Low thermal expansion - Dimensional stability | Electrical insulators, cookware, automotive parts |

Electrical Insulation PPE-PS | - Excellent electrical insulating properties - High dielectric strength - Dimensional stability | Electrical and electronic components, switchgear |

Physical And Mechanical Properties of Injection Molded PPE-PS

Property | Density (g/cm³) | Tensile Strength (MPa) | Tensile Elongation (%) | Flexural Modulus (GPa) | Flexural Strength (MPa) | Izod Impact Strength (J/m) | Heat Deflection Temp. (°C) | Shrinkage (%) | Hardness (HRB) |

|---|---|---|---|---|---|---|---|---|---|

General-Purpose PPE-PS | 1.04 | 50 | 2.5 | 2.5 | 70 | 150 | 95 | 0.6 | 70 |

Flame-Retardant PPE-PS | 1.05 | 55 | 2.0 | 2.3 | 75 | 100 | 100 | 0.7 | 75 |

High-Impact PPE-PS | 1.03 | 60 | 3.0 | 2.8 | 80 | 200 | 85 | 0.5 | 80 |

Heat-Resistant PPE-PS | 1.05 | 45 | 1.5 | 2.2 | 60 | 80 | 110 | 0.8 | 65 |

Electrical Insulation PPE-PS | 1.06 | 45 | 1.0 | 2.0 | 60 | 70 | 120 | 0.8 | 65 |

PPE-PS Grades Injection Molding Properties

General-Purpose PPE-PS

General-purpose PPE-PS (Polyphenylene Ether - Polystyrene) is valued for its balanced properties. It has a density of approximately 1.04 g/cm³ and offers a tensile strength of 50 MPa. Key properties include good heat resistance, chemical resistance, and dimensional stability.

This grade is commonly used in applications such as automotive components, electrical housings, and connectors due to its versatility and ability to maintain its shape and properties under various conditions.

Flame-Retardant PPE-PS

Flame-retardant PPE-PS is engineered to resist combustion and reduce smoke emissions. It typically has a density of around 1.05 g/cm³ and a tensile strength of 55 MPa. In addition to flame resistance, it offers good heat resistance.

This grade finds applications in environments where fire safety is critical, such as electrical and electronics components, aircraft interiors, and HVAC systems.

High-Impact PPE-PS

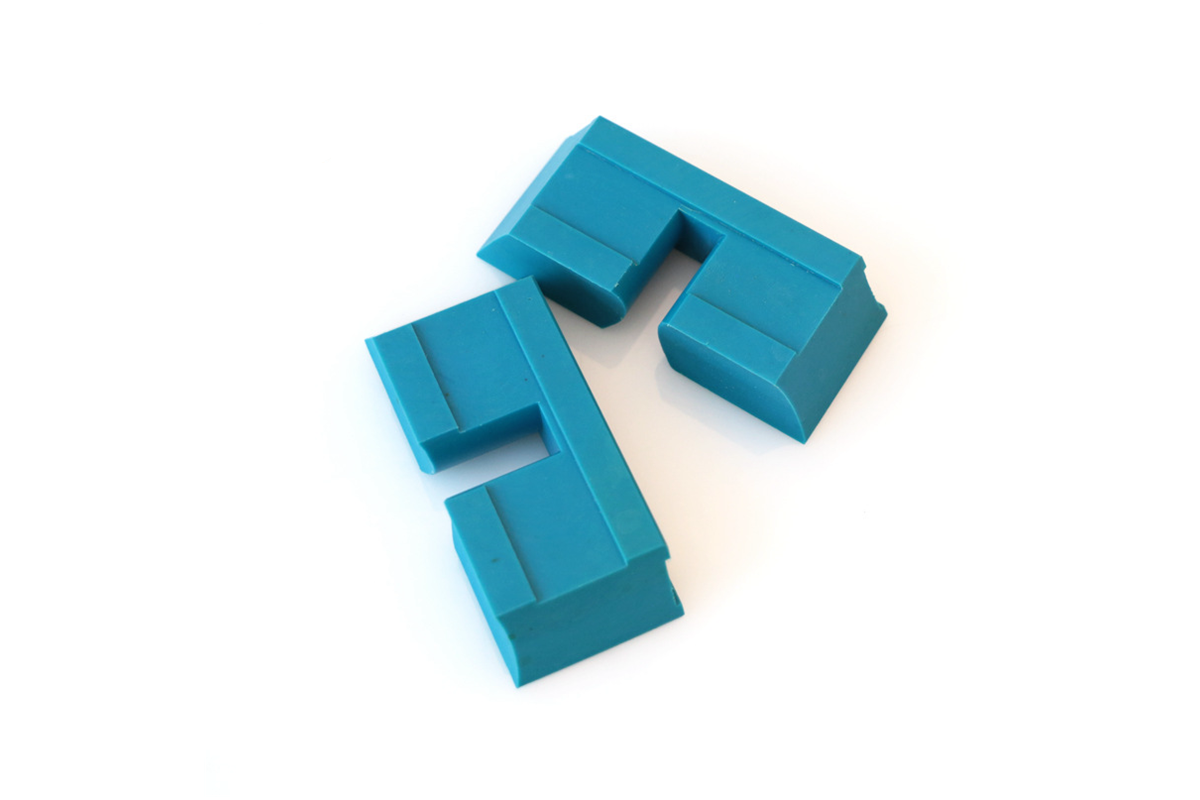

High-impact PPE-PS is recognized for its excellent impact strength and toughness. It has a density of approximately 1.03 g/cm³ and a tensile strength of 60 MPa.

With exceptional dimensional stability, this grade is well-suited for applications subjected to impact loads. Typical uses include automotive bumpers, medical devices, and consumer goods where durability and impact resistance are essential.

Heat-Resistant PPE-PS

Heat-resistant PPE-PS offers exceptional resistance to elevated temperatures. It typically has a density of 1.05 g/cm³ and a tensile strength of 45 MPa. Fundamental properties include low thermal expansion and dimensional stability.

This grade is preferred for applications demanding resistance to heat, such as electrical insulators, cookware, and automotive parts operating in high-temperature environments.

Electrical Insulation PPE-PS

PPE-PS is prized for its excellent electrical insulating properties and high dielectric strength. It has a density of around 1.06 g/cm³ and a tensile strength of 45 MPa. In addition to its electrical characteristics, it exhibits dimensional stability.

This grade is commonly used in electrical and electronic components, switchgear, and applications where electrical insulation is critical to prevent short circuits and ensure safe operation.

Try Design, Quotation, and Prototyping Works For Free

Neway provides free Consultative Design and rapid prototyping services for valid projects for free.

1. CNC Machining Prototyping Service

Correctly fill in your information and send it to our engineer to get free service.

Thermoplastics | Thermosets | |||

Medical-Grade silicone rubber | ||||

Optical silicone rubber | ||||