Why is Overmolding Used?

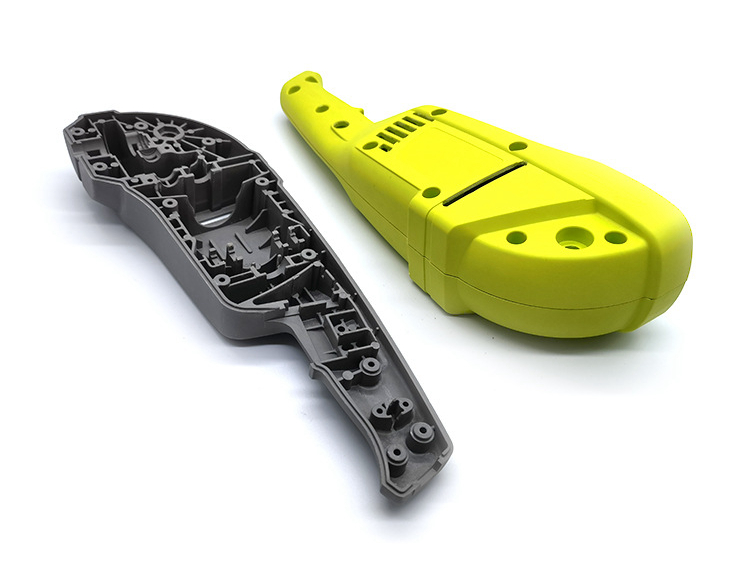

Overmolding refers to a plastic molding process where two or more components are molded over top of one another during sequential operations. It typically involves molding a rigid plastic substrate, then molding a second material like rubber, silicone, or thermoplastic elastomer (TPE) over the substrate in a secondary operation.

Benefits of Overmolding

Overmolding provides several significant benefits, making it a popular manufacturing process across many industries. Below are the key reasons overmolding is commonly utilized:

A significant advantage of overmolding is combining the unique material properties of different plastics or elastomers into a single part. For example, the base material can provide structural rigidity, while the overmold contributes shock absorption, friction, sealing, comfort, or other desired characteristics. It allows for engineering the optimal blend of material performance without manufacturing separate components and assembling them later.

The substrate material is typically an engineered thermoplastic like acrylonitrile butadiene styrene (ABS), polycarbonate (PC), nylon, or polybutylene terephthalate (PBT) chosen for its strength, temperature resistance, durability, and cost. The overmold material may be a thermoplastic elastomer (TPE), silicone, a rubber compound like polyurethane or neoprene, or other suitable elastomers that bond with the substrate. Additives can also enhance properties like conductivity, flame retardance, UV resistance, etc.

Part Consolidation and Assembly

Since overmolding combines multiple components into a single part, allowing considerable consolidation and simplification of parts that would otherwise need to be manufactured separately and assembled. It reduces the overall part count in an assembly and eliminates the need for secondary joining operations.

For example, a handle made of rigid plastic can be over-molded with a gripping silicone layer rather than manufactured separately and then glued on. Or a housing can have gaskets or sealing surfaces molded on rather than created as distinct components that require fastening. The ability to consolidate improves manufacturability, streamlines assembly, and reduces costs.

Design Flexibility

Overmolding provides extensive design flexibility compared to traditional single-shot injection molding. It allows designers only to use the more expensive material where its specific properties are critically needed while utilizing cheaper polymers for the rest of the part. Weight and material savings can be significant.

The location of the overmold area also provides flexibility. Soft touch surfaces for improved grip and ergonomics can be strategically placed right where they are most helpful. Or sealing surfaces can be designed only where sealing is functionally required. The possibilities for part optimization and performance are endless.

Eliminates Secondary Operations

Overmolding often eliminates secondary production steps like adhesive bonding, ultrasonic welding, mechanical fastening, or other joining processes between separate component parts. It improves production efficiency and lowers costs.

For example, multi-component housings can be created in a single overmolding step rather than molding the parts separately and assembling them with screws or ultrasonic welding. Or a soft touch handle can be over-molded rather than glued on as a distinct process. The ability to simplify manufacturing is a crucial benefit.

Enables Sealing, Isolation, and Protection

Since the two materials bond and seal together, overmolding enables effective environmental sealing for components that must be protected from water, moisture, dust, or other contamination. It also provides electrical isolation between conductive parts as needed.

Using a resilient protective cover, overmolding can protect critical substrate components from impact damage, abrasion, UV exposure, chemicals, and other hazards. It benefits electrical, optical, and mechanical components in demanding application environments.

Common Applications

Overmolding is utilized across many industries due to the various benefits outlined above. Some examples of common over-molded parts include:

- Power tools - Grip areas, trigger, power cords, and tool heads over-molded for ergonomics and impact protection.

- Appliances - Soft touch buttons and grips over-molded onto appliance housings and controls.

- Automotive - Interior buttons/knobs, sealings, gaskets, HVAC flaps, shaft bearings.

- Consumer electronics - External rubberized protective cases over-molded onto devices for shock absorption.

- Medical - Elastomer handles and non-slip grips on surgical tools—seals for devices and diagnostic equipment.

- Industrial - Rubber feet and bumpers over-molded onto equipment housings for damping and isolation over-molded gaskets and seals for industrial enclosures.

- Sporting goods - Soft rubber hand grips on tools like golf clubs and tennis rackets.

Overmolding continues to grow in popularity due to its ability to simplify designs, consolidate parts, provide ergonomic and protective features, and enable diverse material properties in a single component. The process is precious across virtually every manufactured product that contains plastic parts or housings. Continued evolution and innovation in overmolding technology and materials will enable even more significant benefits and applications in the future.