When to Select Overmolding for Plastic Injection Molding Projects

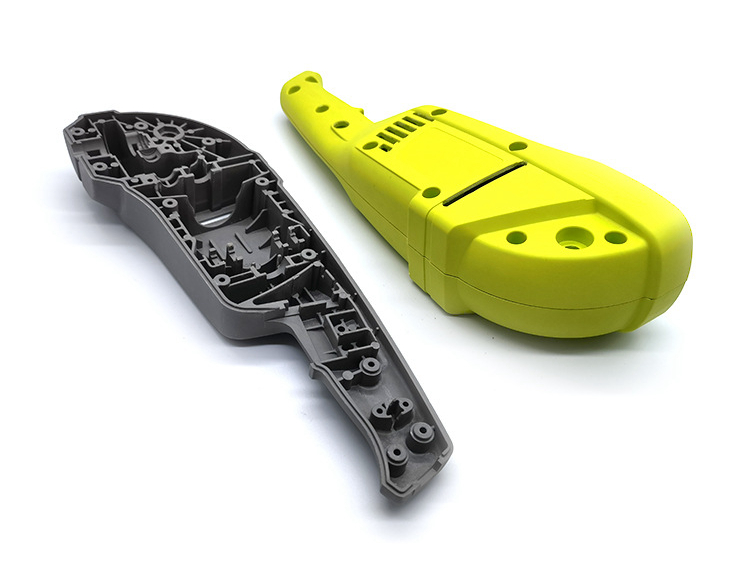

Overmolding is a two-step injection molding process that combines two different plastics into a single part. First, the primary material forms the core component. The core is then transferred to a second mold where the secondary material is injection molded over it.

Combining Material Properties

A key benefit of overmolding is integrating attributes of different plastics into one part. A rigid engineering thermoplastic can be used for the structural core, while a soft thermoplastic elastomer or rubber material provides friction, grip, or impact absorption. For example, tool handles have a rigid inner core over-molded with a soft outer grip. It provides comfort and torque transfer to the user.

Eliminating Assembly

Since the two materials are fusion bonded together during molding, no additional assembly is required post-molding. It reduces overall production costs and time. For components like power tools that utilize a hard plastic body with a rubber grip, overmolding eliminates the need to assemble the grip over the tool handle as a separate step.

Enhancing Aesthetics

Overmolding allows the combining plastic materials with different textures, colors, or finishes. A knurled metal-like finish can be achieved by overmolding a metallic-coated plastic over a colored core. Soft-touch TPE material for the secondary overmold can provide an appealing look and feel. This aesthetic enhancement is difficult to achieve with standard injection molding in a single shot.

Improving Bond Strength

The fusion bonding of the two materials under heat and pressure creates a solid mechanical interlock between them. Compared to gluing or welding plastic parts together post-production, it improves long-term bond strength. Robust bonding prevents delamination during service life for critical components like medical devices and automotive interiors.

Lowering Per-unit Costs

For low to medium production volumes, overmolding can lower overall manufacturing costs by reducing secondary operations, assembly, and finishing steps. The labor for manual assembly and post-molding processes is avoided. However, the additional molding step can increase costs for very high volumes compared to standard injection molding.

Simplifying Electrical Insulation

Sensitive electronic products often require plastic parts to be molded using insulation-safe thermoplastics. But these materials may need more desired aesthetics or wear properties. Both requirements can be met by overmolding insulation grade material internally and aesthetically pleasing polymers externally. It is a common technique for consumer electronics.

Customizing Feel and Grips

Overmolding provides extensive flexibility in customizing the feel, grip, comfort, and handling of products ranging from hand tools, appliances, consumer goods, medical devices, and automotive interiors. Materials like TPE can provide soft, tactile grips tailored to ergonomics and usage.

Improving Impact Resistance

For applications requiring protection from impacts and drops, a rigid yet flexible TPE or rubber material can be over-molded onto housings made of rigid engineering plastic—the soft overmold acts as a cushion by absorbing and dampening impact energy. The rigid substrate provides structural integrity. This approach is used in protective cases, sporting goods, and industrial equipment.

Masking Aesthetic Shortcomings

Sometimes base resins may have excellent strength, heat resistance, and electrical properties but lack visual appeal. By overmolding with a more aesthetically pleasing plastic can mask this shortcoming while retaining optimal internal properties. High-filler glass-reinforced plastics often benefit from this overmolding approach.

Simplifying Multi-material Molding

Some applications require combining multiple separate plastic components—for example, metalized plastics combined with clear see-through windows. Rather than molding and assembling them separately, they can be integrated through overmolding for reliability and cost benefits.

Improving Part-Dimensional Stability

Materials like glass-reinforced plastics (GRP) provide high strength but tend to warp and shrink after molding. It can be countered by overmolding a precise secondary resin layer to achieve more dimensionally stable components. Automotive lenses use this technique.

Overmolding provides technical and economic benefits over standard injection molding for specific applications. When requirements include combining dissimilar materials, enhancing aesthetics, improving impact strength, eliminating assembly, or lowering fabrication costs, overmolding presents an excellent production solution.

Customer Testimonial

"We've used other injection molding suppliers in the past, but no one compares to the quality and precision we get from Neway. Their expertise in everything from plastics to casting metal parts is awe-inspiring. And their rapid prototyping services are invaluable for testing new product designs quickly. We're so pleased with Neway's work that they've become our go-to source for all non-standard parts for over 5 years now." - Sarah M., Manufacturing Manager