MIM Ti-5Al-2.5Fe (Grade 38)

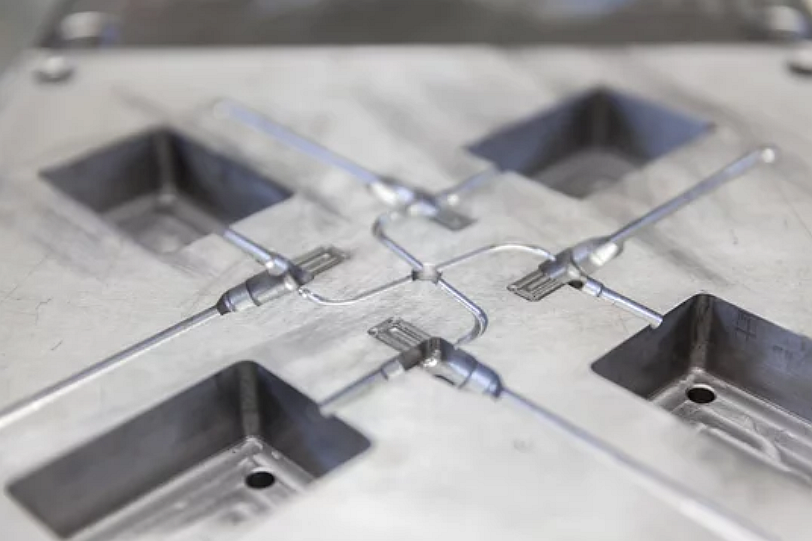

Ti-5Al-2.5Fe (Grade 38) Titanium Injection Molding

Ti-5Al-2.5Fe (Grade 38) Injection Moulding parts

Ti-5Al-2.5Fe (Grade 38) materials exhibit distinct properties when used in metal injection molding (MIM). This alloy is renowned for its exceptional corrosion resistance, making it an excellent choice for applications where exposure to harsh environments is a concern. It retains its integrity even when subjected to aggressive chemicals and outdoor conditions, making it suitable for components in chemical processing equipment and outdoor structures.

Additionally, Ti-5Al-2.5Fe (Grade 38) offers impressive mechanical properties. It combines good tensile strength and yield strength with a notable impact resistance, making it versatile for various applications. Its hardness and formability enhance its usability in MIM processes.

MIM / PCM Titanium Alloys Neway Use:

Typical Properties Of MIM Ti-5Al-2.5Fe (Grade 38)

Chemical Composition Of MIM Ti-5Al-2.5Fe (Grade 38)

Element | Titanium (Ti) | Aluminum (Al) | Iron (Fe) |

|---|---|---|---|

Composition (%) | 90.0% | 5.0% | 5.0% |

MIM Ti-5Al-2.5Fe (Grade 38) Physics and Mechanical Properties

Property | Status | Tensile Strength (MPa) | Yield Strength (MPa) | Impact Strength (J) | Hardness (HRC) | Young's Modulus (GPa) | Poisson's Ratio | Elongation (%) | Density (g/cm³) |

|---|---|---|---|---|---|---|---|---|---|

Values | As Sintered | 690 | 620 | 30 | 28 | 115 | 0.34 | 12 | 4.50 |

Applications and Benefits of Ti-5Al-2.5Fe (Grade 38) Injection Moulding Parts

Ti-5Al-2.5Fe (Grade 38) Injection Moulding Marine Equipment

Ti-5Al-2.5Fe (Grade 38) injection molding parts find significant applications in the marine equipment industry, contributing to the durability and performance of various components in a marine environment. One primary use is in the manufacturing of marine fasteners and fittings. The exceptional corrosion resistance of this alloy ensures that these parts can withstand the harsh conditions of saltwater exposure without rusting or degrading over time.

Furthermore, Ti-5Al-2.5Fe (Grade 38) produces marine exhaust systems and components. These parts are subjected to high temperatures and corrosive gases from engine exhausts. The alloy's resistance to both heat and corrosion makes it an ideal choice for these critical components, ensuring they can endure the demanding conditions of marine propulsion systems.

Ti-5Al-2.5Fe (Grade 38) Injection Moulding Chemical Processing Equipment Parts

Ti-5Al-2.5Fe (Grade 38) injection molding parts are precious in chemical processing equipment due to their exceptional corrosion resistance and mechanical properties. One prominent application is in the manufacturing of chemical valves and fittings. These components must withstand the corrosive effects of various chemicals, acids, and bases. Ti-5Al-2.5Fe's resistance to corrosion ensures that these parts remain durable and reliable over time, even when exposed to aggressive chemical environments.

Additionally, Ti-5Al-2.5Fe is used to produce heat exchangers and reaction vessels within the chemical industry. These components often operate under elevated temperatures and pressure, making the alloy's heat resistance and strength valuable attributes. Its ability to maintain structural integrity in such conditions contributes to the efficiency and safety of chemical processes.

Ti-5Al-2.5Fe (Grade 38) Injection Moulding Automotive Components

Ti-5Al-2.5Fe (Grade 38) injection molding parts have found valuable applications in the automotive industry, particularly in manufacturing critical components that benefit from their unique properties. One primary application is in the production of exhaust systems. These parts are subjected to high temperatures and corrosive gases from engine exhausts. Ti-5Al-2.5Fe's exceptional heat and corrosion resistance make it an ideal choice for manufacturing exhaust components.

Furthermore, Ti-5Al-2.5Fe (Grade 38) creates lightweight yet durable engine components. This alloy's excellent strength and low-density combination make it suitable for parts such as valves and connecting rods. These components reduce the engine's weight and enhance its efficiency and power output.

Ti-5Al-2.5Fe (Grade 38) Injection Moulding Sports Equipment Parts

Ti-5Al-2.5Fe (Grade 38) injection molding parts have carved a niche in the sports equipment industry, contributing to developing high-performance gear. One prominent application lies in bicycle components. The alloy's lightweight properties make it ideal for manufacturing bicycle frames and components. Cyclists benefit from the reduced weight, enhancing agility and speed and improving their performance.

Moreover, Ti-5Al-2.5Fe (Grade 38) produces golf club heads. These parts require materials that combine strength and lightweight characteristics to optimize golfers' swings. The alloy's durability and resistance to corrosion ensure that golf clubs maintain their performance and appearance over time.

Try Neway Prototyping Service For Free

Neway provides free Consultative Design and rapid prototyping services for valid projects for free.

1. CNC Machining Prototyping Service

Correctly fill in your information and send it to our engineer to get free service.

MIM FAQs

1. What is metal injection molding used for?

2. What are the factors affecting the tolerance of MIM parts?

3. Which materials are suitable for metal injection molding?

4. What Is The Shrinkage of Metal Injection Molding?

5. 10 Reasons Why MIM Metal Powders Are More Expensive Than Common Bulk Metal Materials?

6. What Are The Applications of Thin-Walled MIM Parts Across Industries?