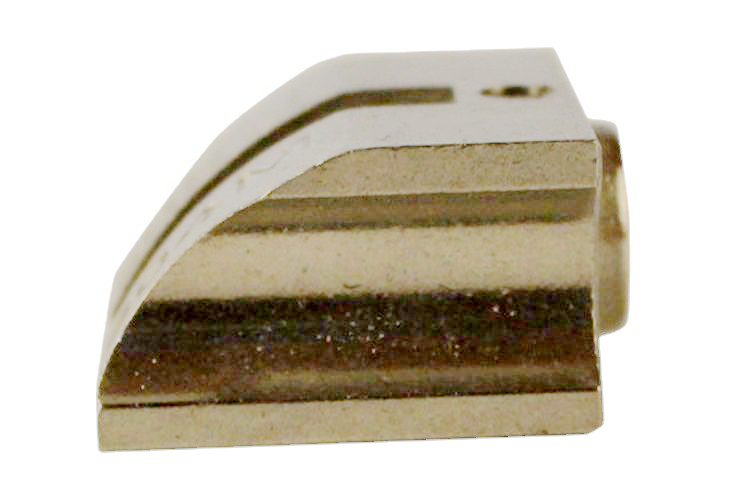

MIM-Stellite 6

MIM-Stellite 6 Injected Parts Manufacturer

Sintered Stellite 6 MIM Power Tool Parts

Sintered Stellite 6 MIM parts are components made from Stellite 6, a cobalt-based alloy known for its exceptional wear resistance, corrosion resistance, and high-temperature stability. These parts are manufactured using the Metal Injection Molding (MIM) process, allowing for intricate and precise designs.

Typical applications of sintered Stellite 6 MIM parts in power tools include:

Cutting Blades

Bearings

Tool Bits

Valve Seats

Wear Plates

Typical Properties of MIM-Stellite 6 Cobalt Alloy

MIM-Stellite 6 Chemical Composition

Cobalt (Co) | Chromium (Cr) | Tungsten (W) | Carbon (C) | Silicon (Si) | Iron (Fe) |

|---|---|---|---|---|---|

60% | 29% | 9% | 0.7% | 0.7% | 0.3% |

MIM-Stellite 6 Physics and Mechanical Properties

Status | Tensile Strength (MPa) | Yield Strength (MPa) | Impact Strength (J) | Hardness (HRC) | Young's Modulus (GPa) | Poisson's Ratio | Elongation (%) | Density (g/cm³) |

|---|---|---|---|---|---|---|---|---|

As Sintered | 800 | 600 | 25 | 30 | 220 | 0.3 | 5 | 8.4 |

MIM-Stellite 6 Injection Molded Applications

MIM-Stellite 6 injection-molded Cutting Blades

MIM-Stellite 6 injection-molded cutting blades offer various benefits indispensable in various industrial applications. Firstly, these cutting blades are renowned for their exceptional wear resistance, a critical attribute when dealing with abrasive materials and demanding cutting tasks. Stellite 6's ability to maintain sharp edges and resist wear even under heavy use ensures prolonged blade life, reducing downtime and the need for frequent replacements.

Secondly, Stellite 6 cutting blades provide superior corrosion resistance, making them suitable for applications in harsh and corrosive environments. Whether used in marine, chemical, or outdoor settings, these blades maintain their structural integrity and cutting efficiency, even when exposed to moisture and corrosive substances.

MIM-Stellite 6 Injection molding Bearings

MIM-Stellite 6 injection-molded bearings are indispensable components in various industrial and mechanical applications. These bearings are renowned for their exceptional wear resistance, a critical feature when considering their role in supporting rotating machinery. Stellite 6's ability to withstand friction and abrasion ensures that these bearings have a prolonged service life, reducing the need for frequent replacements and maintenance.

Secondly, Stellite 6 bearings provide superior corrosion resistance, making them suitable for use in challenging environments, including those exposed to moisture, chemicals, and temperature variations. Their corrosion resistance ensures that these bearings maintain their structural integrity and load-bearing capacity over time, reducing the risk of premature failure and costly downtime. Furthermore, the precision attainable through the injection molding process allows for the creation of intricately designed bearings, optimizing their performance and efficiency in various machinery and equipment.

MIM-Stellite 6 MIM sintering Valve Seats

MIM-Stellite 6 MIM sintered valve seats are essential components in industries where reliable and durable valve systems are critical. Firstly, these valve seats are renowned for their exceptional wear resistance, a crucial attribute when considering their role in controlling fluid flow in demanding environments. Stellite 6's ability to resist wear and maintain its dimensional stability even under high-temperature and high-pressure conditions ensures the longevity of valve systems.

Secondly, Stellite 6 valve seats offer outstanding corrosion resistance, making them ideal for use in environments exposed to corrosive fluids and chemicals. Their corrosion resistance ensures valve seats maintain their sealing properties and structural integrity over time, reducing the risk of leaks and system failures.

MIM-Stellite 6 MIM sintered Wear Plates

MIM-Stellite 6 MIM sintered wear plates are indispensable components for their exceptional wear resistance and versatility in various industrial applications. Firstly, these wear plates are renowned for their ability to withstand extreme wear and abrasion. Stellite 6's exceptional hardness and wear resistance make it an ideal material for wear plates, ensuring that they maintain their structural integrity and protect vital equipment surfaces even in high-stress conditions. Whether used in mining, construction, or manufacturing, these wear plates significantly extend the service life of machinery and reduce maintenance costs.

Secondly, Stellite 6 wear plates offer outstanding corrosion resistance, making them suitable for harsh and corrosive environments. Their corrosion resistance ensures that wear plates remain effective over time, reducing the risk of material degradation and equipment failure.

Brand Case Study

Neway has served many world-renowned companies, using its strong manufacturing capabilities and complete quality control system to provide further market competitiveness and quality assurance for major brands.