MIM-M2

MIM-M2 Tool Steel Injection Molding

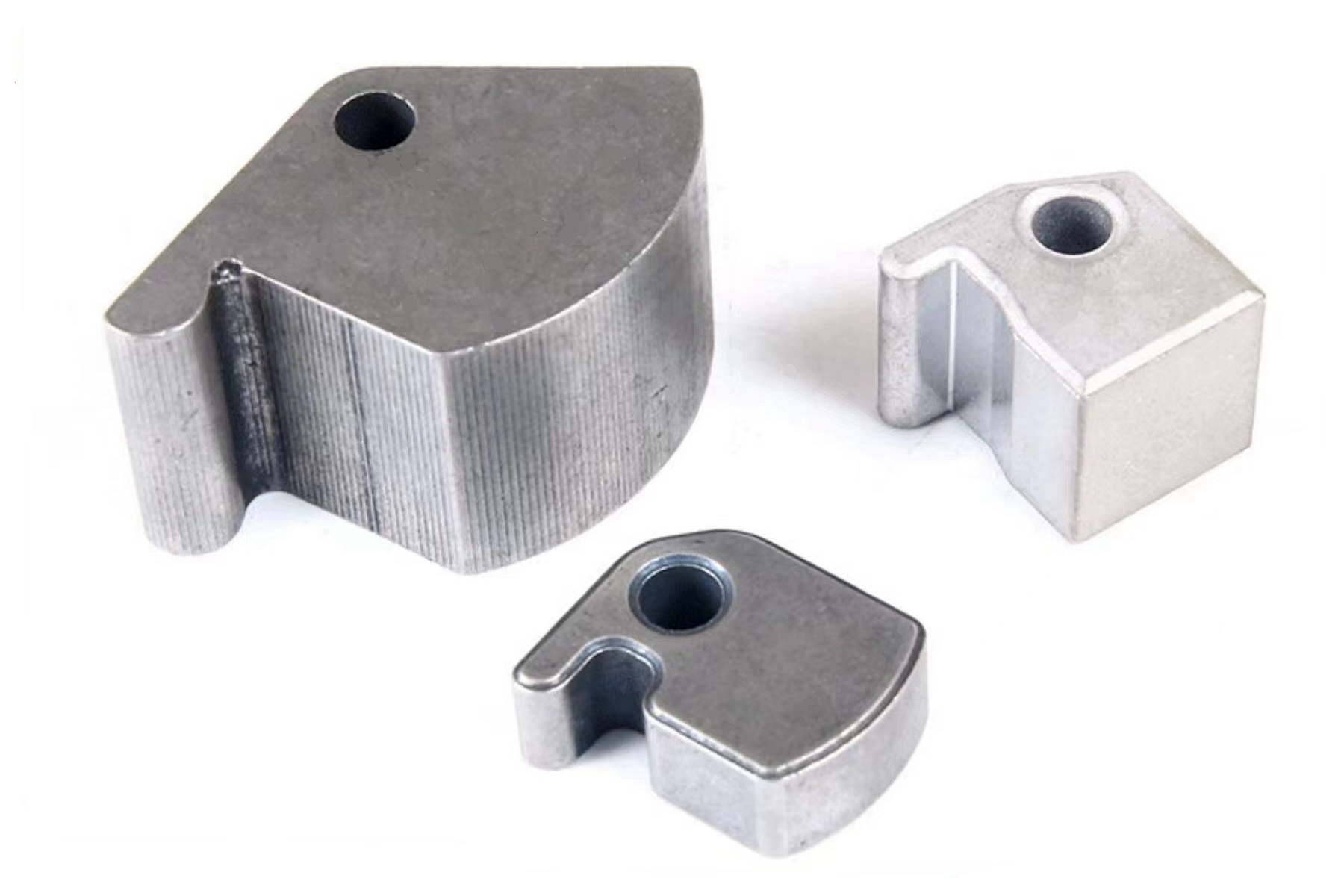

M2 Tool Steel Injection Moulding parts

M2 Tool Steel injection molding parts exhibit exceptional properties in various industries, including Consumer Electronics and Power Tools. M2 Tool Steel parts are capable of withstanding the rigorous demands of manufacturing processes. With a Rockwell hardness of up to 64 HRC, these components maintain their structural integrity even in high-stress applications, ensuring prolonged service life.

Furthermore, M2 Tool Steel's high-precision attributes make it ideal for Telecommunication and Lighting Solutions applications. Its fine-grained microstructure, with a grain size as small as 2 micrometers, guarantees precise dimensions and tolerances. This precision is especially critical in telecommunications, where even minor deviations can affect signal integrity. In Lighting Solutions, M2 Tool Steel's ability to retain its hardness at elevated temperatures ensures consistent performance over time.

Typical applications:

Antenna mounting hardware

Fiber optic cable connectors

RF and microwave components

Lamp sockets and connectors

Streetlight hardware

Typical Properties Of MIM-M2 Tool Steel

Chemical Composition Of MIM-M2 Tool Steel

Element | Carbon (C) | Chromium (Cr) | Vanadium (V) | Molybdenum (Mo) | Tungsten (W) | Silicon (Si) | Manganese (Mn) |

|---|---|---|---|---|---|---|---|

Composition (%) | 0.95 | 4.25 | 2.00 | 5.00 | 6.50 | 0.45 | 0.27 |

MIM-M2 Tool Steel Physics and Mechanical Properties

Property | Status | Tensile Strength (MPa) | Yield Strength (MPa) | Impact Strength (J) | Hardness (HRC) | Young's Modulus (GPa) | Poisson's Ratio | Elongation (%) | Density (g/cm³) |

|---|---|---|---|---|---|---|---|---|---|

MIM-M2 Tool Steel | As Sintered | 850 | 760 | 20 | 63.5 | 209 | 0.29 | 6.5 | 7.80 |

Applications of M2 Tool Steel Injection Moulding parts

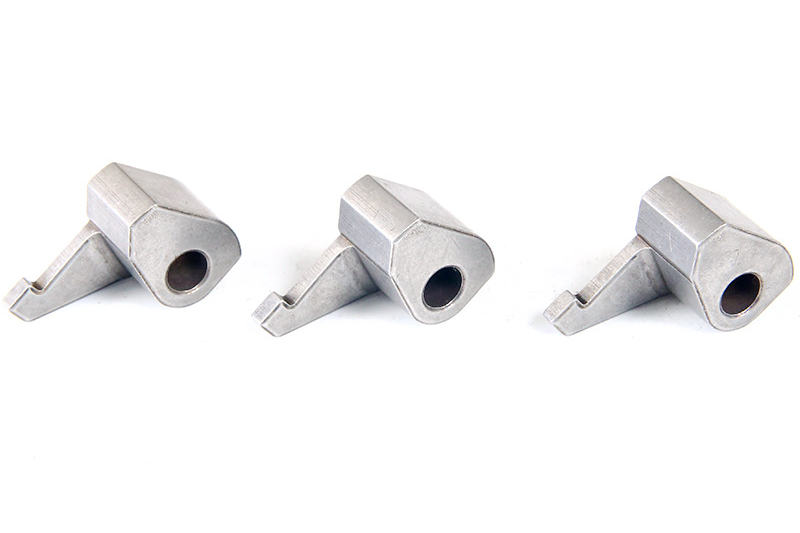

M2 Tool Steel Injection Moulding Antenna Mounting Hardware

M2 Tool Steel injection moulding parts are an excellent choice for antenna mounting hardware in the Telecommunication industry due to their exceptional properties. The high tensile strength of M2 Tool Steel, typically exceeding 850 MPa, ensures antenna mounts' structural integrity and stability, even in challenging outdoor conditions.

Moreover, M2 Tool Steel's outstanding hardness of around 63.5 HRC and precise dimensions contribute to the longevity and durability of antenna mounting hardware. It ensures that these components can withstand environmental stressors, such as exposure to harsh weather conditions or mechanical vibrations, while maintaining their form and function.

M2 Tool Steel Injection Moulding Fiber Optic Cable Connectors

M2 Tool Steel injection moulding parts are highly suitable for fiber optic cable connectors, especially in the telecommunication industry. These connectors demand precision and durability to maintain the integrity of optical signals. M2 Tool Steel's exceptional hardness, typically around 63.5 HRC, ensures that the connectors maintain their precise dimensions over time, critical for accurate signal transmission. Its low susceptibility to wear and abrasion guarantees a prolonged lifespan in the demanding field of fiber optics.

Additionally, M2 Tool Steel's high tensile strength, often exceeding 850 MPa, provides the necessary structural support for fiber optic cable connectors. This strength ensures the connectors can withstand mechanical stresses and environmental conditions while securely holding fiber optic cables.

M2 Tool Steel Injection Moulding Lamp Sockets

M2 Tool Steel injection moulding parts find a valuable application in lamp sockets and connectors within the Lighting Solutions industry due to their remarkable properties. Lamp sockets and connectors require materials that can endure high temperatures and mechanical stress, ensuring the safety and reliability of lighting fixtures.

Furthermore, the high precision and dimensional stability of M2 Tool Steel parts, attributed to their fine-grained microstructure and specific composition, guarantee a secure and consistent fit for bulbs and connectors. This precision is crucial in the Lighting Solutions sector, where even minor deviations can affect the alignment of lighting fixtures. M2 Tool Steel injection molding parts, with their combination of hardness, heat resistance, and precision, contribute significantly to the reliability and longevity of lamp sockets and connectors, ensuring efficient lighting systems for various applications.

M2 Tool Steel Injection Moulding Streetlight Hardware

M2 Tool Steel injection moulding streetlight hardware must withstand various environmental challenges, including exposure to harsh weather conditions and potential vandalism. M2 Tool Steel, known for its exceptional hardness, typically around 63.5 HRC, ensures that these components maintain their structural integrity even in demanding outdoor settings. This hardness provides the necessary durability to withstand impacts and resist wear over time, enhancing the longevity of streetlight hardware.

Additionally, M2 Tool Steel's high tensile strength, typically exceeding 850 MPa, contributes to the robustness of streetlight hardware, enabling it to securely support the weight of lighting fixtures and withstand mechanical stresses. Its corrosion resistance is also advantageous in outdoor environments, where exposure to moisture and other elements is expected.

Neway Custom Manufacturing Capability

Neway has gradually improved the production system of basic hardware, plastic, and ceramic non-standard parts after 30 years of growth from the original CNC workshop. As well as polishing, PVD, and simple assembly lines. Provide one-stop, non-standard manufacturing services to our customers.