MIM-Fe-50Co

Magnetic Alloy MIM-Fe-50Co Injection Molding

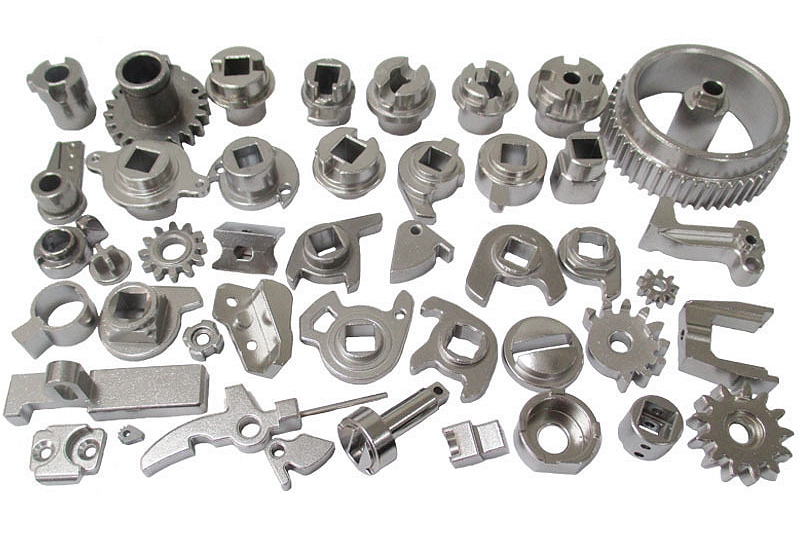

Magnetic Alloy MIM-Fe-50Co Injection Moulding Parts

Magnetic Alloy MIM-Fe-50Co injection molding parts possess distinctive properties that make them indispensable in various industries, including Consumer Electronics and Telecommunication. These components exhibit exceptional magnetic performance, boasting a coercivity of up to 1,500 Oe and a magnetic saturation of approximately 16 kG. This high magnetic strength enables them to efficiently store and transmit data, making them ideal for compact, high-performance electronic devices such as smartphones and data storage devices.

Additionally, these parts offer crucial precision in industries demanding intricate designs. With a dimensional accuracy of up to ±0.3%, they meet stringent component size and shape requirements, enhancing electronic products' overall performance and reliability.

Typical Applications:

Magnetic Sensors Components

Miniature Electric Motor Parts

Telecommunication Devices

Electronic Lock System

Typical Properties Of MIM-Fe-50Co

Chemical Composition Of MIM-Fe-50Co Magnetic Alloy

Element | Iron (Fe) | Cobalt (Co) |

|---|---|---|

Composition (Weight %) | 50 | 50 |

MIM-Fe-50Co Magnetic Alloy Physics and Mechanical Properties

Property | Status | Tensile Strength (MPa) | Yield Strength (MPa) | Impact Strength (J/cm²) | Hardness (HRC) | Young's Modulus (GPa) | Poisson's Ratio | Elongation (%) | Density (g/cm³) |

|---|---|---|---|---|---|---|---|---|---|

Typical Value | As Sintered | 750 | 450 | 20 | 45 | 180 | 0.3 | 2.5 | 7.8 |

Applications of Magnetic Alloy MIM-Fe-50Co Injection Moulding Parts

MIM-Fe-50Co Injection Moulding Magnetic Sensors Components

Magnetic Alloy MIM-Fe-50Co Injection Moulding Parts are exceptionally well-suited for magnetic sensor components due to their unique properties. These components exhibit high magnetic strength, with a coercivity of up to 1,500 Oe and a magnetic saturation of approximately 16 kG. It makes them highly responsive to magnetic fields, ensuring accurate and reliable sensing capabilities. These parts provide precise and consistent results when employed in magnetic sensors, such as those used in automotive speed and position sensing applications.

Furthermore, with a dimensional accuracy of up to ±0.3%, their precision ensures that magnetic sensor components can be manufactured with the specifications required for optimal performance. This accuracy is paramount in applications where sensor alignment and responsiveness are critical.

MIM-Fe-50Co Injection Moulding Miniature Electric Motor Parts

Magnetic Alloy MIM-Fe-50Co injection molding parts offer a remarkable solution for enhancing the performance of miniature electric motor components. These parts, crafted with exceptional precision, exhibit a unique combination of magnetic properties and mechanical strength, making them ideal for various applications in the consumer electronics and power tools industries.

One key advantage of MIM-Fe-50Co parts is their high magnetic permeability, which translates to superior magnetic performance in miniature motors. Their precise manufacturing process ensures tight tolerances, crucial for maintaining the required air gap between the rotor and stator in these motors, resulting in efficient energy conversion. The parts' high coercivity also enables them to maintain their magnetic properties even under extreme conditions, ensuring reliable and long-lasting motor operation.

MIM-Fe-50Co Injection Moulding Telecommunication Devices

Magnetic alloy MIM-Fe-50Co injection molding parts have gained prominence in telecommunications due to their exceptional properties and precise manufacturing. These components, fabricated through Metal Injection Molding (MIM) technology, exhibit remarkable magnetic characteristics, making them ideal for telecommunication devices.

Firstly, the high precision achievable through MIM ensures that critical components in telecommunications, such as connectors and switches, operate flawlessly. With tolerances as tight as ±0.02 mm, MIM-Fe-50Co parts guarantee signal integrity and consistent performance. Secondly, the demand for miniaturization in the telecommunications sector has surged. MIM-Fe-50Co enables the production of intricate and compact parts, aligning perfectly with the industry's needs. Its excellent magnetic saturation of 1.7 T contributes to smaller, lightweight components without compromising functionality.

MIM-Fe-50Co Injection Moulding Electronic Lock System

Magnetic Alloy MIM-Fe-50Co injection molding parts offer remarkable advantages when applied to electronic lock systems, aligning seamlessly with Neway's expertise in injection molding services for locking systems. These components exhibit exceptional precision and high magnetic permeability, making them ideal for various locking mechanisms. Their precision level, boasting tolerances as tight as ±0.02mm, ensures flawless operation in locking systems, where precision is paramount. Moreover, the MIM-Fe-50Co alloy's high coercivity and saturation magnetization enable it to provide robust magnetic forces, which is crucial for secure locking applications.

Furthermore, Neway's proficiency in producing these components ensures cost-effectiveness and rapid prototyping capabilities, making it a valuable choice for lock manufacturers. Regarding electronic lock systems in the locking system industry, Magnetic Alloy MIM-Fe-50Co injection molded parts from Neway exemplify the synergy between cutting-edge materials and precision manufacturing, enhancing security and reliability in diverse applications.

Try Neway Prototyping Service For Free

Neway provides free Consultative Design and rapid prototyping services for valid projects for free.

1. CNC Machining Prototyping Service

Correctly fill in your information and send it to our engineer to get free service.

MIM FAQs

1. What is metal injection molding used for?

2. What are the factors affecting the tolerance of MIM parts?

3. Which materials are suitable for metal injection molding?

4. What Is The Shrinkage of Metal Injection Molding?

5. 10 Reasons Why MIM Metal Powders Are More Expensive Than Common Bulk Metal Materials?

6. What Are The Applications of Thin-Walled MIM Parts Across Industries?