MIM-D2

MIM-D2 Tool Steel Injection Molding

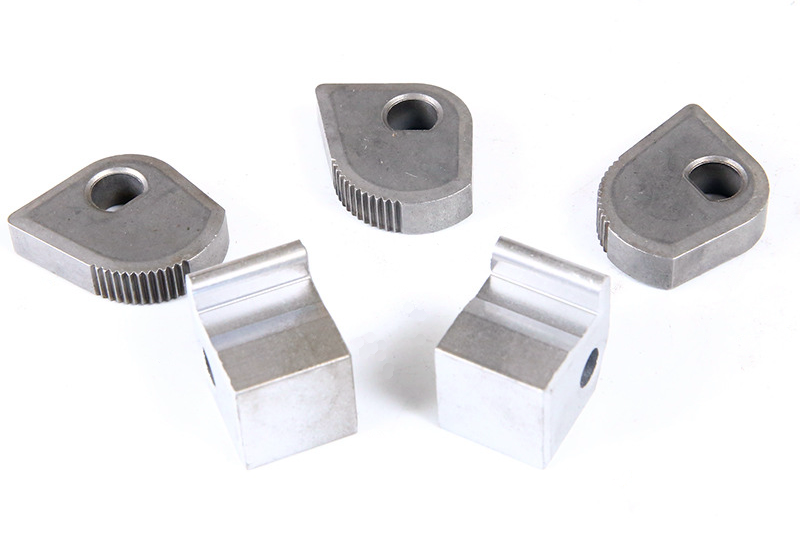

D2 Tool Steel Injection Molded Parts

D2 Tool Steel Injection Molded Parts possess unique properties. Firstly, their exceptional hardness, with a Rockwell C hardness of 58-62, ensures superior wear resistance and long-term performance, making them ideal for applications requiring durability and precision.

Secondly, D2 Tool Steel parts exhibit outstanding machinability and ease of heat treatment. This versatility enables intricate geometries and customizations, enhancing their adaptability to different production requirements. Additionally, their resistance to deformation under high temperatures makes them suitable for consumer electronics and power tools applications.

Typical applications like:

Electric vehicle charging connectors

Electronic and smart lock components

Charging station components

Impact wrench and driver components

High-precision reflectors and reflector holders

Typical Properties Of MIM-D2 Tool Steel

Chemical Composition Of MIM-D2 Tool Steel

Element | Carbon (C) | Chromium (Cr) | Manganese (Mn) | Silicon (Si) | Vanadium (V) |

|---|---|---|---|---|---|

Composition (%) | 1.45 | 11.50 | 0.40 | 0.35 | 0.90 |

MIM-D2 Tool Steel Physics and Mechanical Properties

Property | Status | Tensile Strength (MPa) | Yield Strength (MPa) | Impact Strength (J) | Hardness (HRC) | Young's Modulus (GPa) | Poisson's Ratio | Elongation (%) | Density (g/cm³) |

|---|---|---|---|---|---|---|---|---|---|

MIM-D2 Tool Steel | Heat Treated | 780 | 680 | 14 | 58 | 210 | 0.28 | 15 | 7.8 |

Applications of D2 Tool Steel Injection Molded Parts

D2 Tool Steel Injection Molded Charging Connectors

D2 Tool Steel Injection Molded Electric Vehicle (EV) charging connectors offer a range of significant benefits that contribute to the efficiency and durability of EV charging systems. D2 Tool Steel's exceptional hardness and wear resistance ensures a prolonged connector lifespan even under rigorous usage.

Secondly, the precise dimensional stability of D2 Tool Steel enhances the accuracy and consistency of these connectors. It is especially vital in EV charging, where precise alignment is crucial for efficient charging and minimizing energy loss. Additionally, its resistance to deformation under high temperatures and mechanical stress ensures long-lasting performance, meeting the demanding requirements of electric vehicle charging systems. In summary, D2 Tool Steel Injection Molded Electric Vehicle charging connectors stand out for their durability, precision, and reliability, making them a preferred choice to support the expanding electric mobility ecosystem.

D2 Tool Steel Injection Molded Lock Components

D2 Tool Steel Injection Molded Lock Components offer an array of advantages that enhance the security and longevity of locking systems. Firstly, their exceptional hardness and wear resistance make them ideal for manufacturing lock components, ensuring extended durability and resistance to wear and tear. It is vital in the locking system industry, where components must withstand frequent usage and potential tampering.

Secondly, the precision achievable with D2 Tool Steel molding results in intricate and finely detailed lock components. This precision is crucial for creating complex locking mechanisms that provide high-security levels. D2 Tool Steel's dimensional stability guarantees consistent and reliable lock performance over time, contributing to users' overall security and peace of mind. In conclusion, D2 Tool Steel Injection Molded Lock Components are renowned for their durability, precision, and reliability, making them a preferred choice for crafting secure and long-lasting locking systems.

D2 Tool Steel Injection Molded Charging Station Components

D2 Tool Steel Injection Molded Charging Station Components offer a range of compelling benefits that significantly contribute to the efficiency and durability of electric vehicle (EV) charging infrastructure. D2 Tool Steel's exceptional hardness and wear resistance make it an ideal choice for these components. They can withstand the rigorous demands of EV charging stations, ensuring long-term reliability and reduced maintenance costs.

Secondly, the precision and dimensional stability of D2 Tool Steel contribute to the accurate and consistent performance of charging station components. This precision is critical in maintaining seamless connections between the charger and the EV, minimizing energy loss and ensuring efficient charging. Moreover, D2 Tool Steel's resistance to deformation under high temperatures and mechanical stress ensures that these components can endure the demands of continuous use. In summary, D2 Tool Steel Injection Molded Charging Station Components offer durability, precision, and reliability, making them a key component in supporting the growth of the electric vehicle charging infrastructure.

D2 Tool Steel Injection Molded Impact Wrench Components

D2 Tool Steel Injection, Molded Impact Wrench Components provide several key advantages that enhance the performance and longevity of impact wrenches in various industries. Firstly, D2 Tool Steel's exceptional hardness and wear resistance make it an excellent choice for manufacturing these components. They can withstand the high torque and mechanical stresses from impact wrenches, ensuring extended durability and reduced wear.

Secondly, the precision achievable through D2 Tool Steel molding results in finely detailed and accurately manufactured components. This precision is crucial for maintaining the efficiency and reliability of impact wrenches, which are commonly used in automotive and industrial settings. Additionally, D2 Tool Steel's dimensional stability guarantees consistent performance, allowing impact wrenches to deliver reliable and precise results with every use. In summary, D2 Tool Steel Injection Molded Impact Wrench Components offer durability, precision, and reliability, making them essential for high-performance impact wrenches across various industries.

Industries We Cover In Metal Injection Molding

As an experienced metal injection molding manufacturer, Neway is involved in many industries and trusted by big brand companies.

The industries we cover include:

Case Study: