MIM-CoNiCrMo

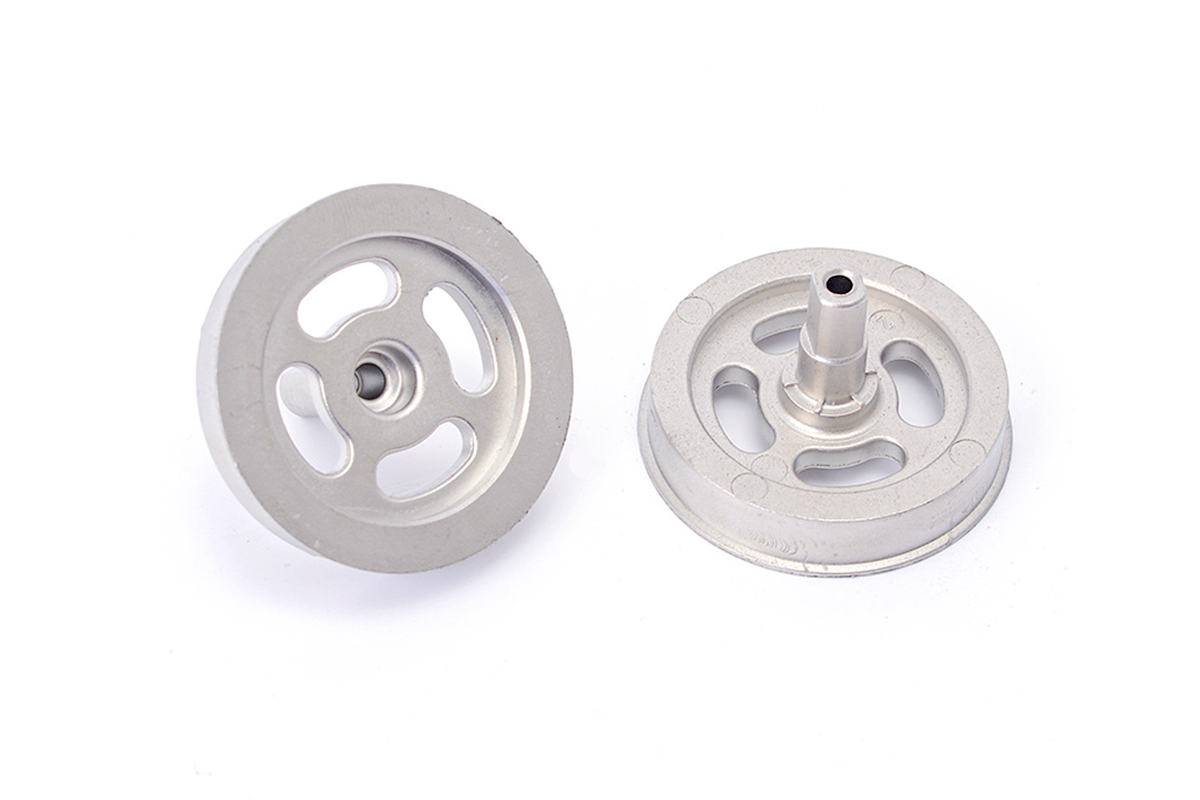

MIM-CoNiCrMo Injection Molded Parts Manufacturer

CoNiCrMo Injection Molding Parts In the Energy Industry

CoNiCrMo injection molding parts are components produced from an alloy primarily composed of cobalt (Co), nickel (Ni), chromium (Cr), and molybdenum (Mo). This alloy is known for its exceptional corrosion resistance, high-temperature stability, and mechanical strength, making it ideal for demanding applications in the energy industry.

Typical applications of CoNiCrMo injection molding parts in the energy industry include:

Turbine Components

Valve and Pump Components

Heat Exchanger Components

Nuclear Power Plant Components

Oil and Gas Exploration

Typical Properties of MIM-CoNiCrMo Cobalt Alloy

MIM-CoNiCrMo Chemical Composition

Cobalt (Co) | Nickel (Ni) | Chromium (Cr) | Molybdenum (Mo) | Iron (Fe) | Carbon (C) | Silicon (Si) | Phosphorus (P) | Sulfur (S) |

|---|---|---|---|---|---|---|---|---|

30.0% | 30.0% | 20.0% | 10.0% | 5.0% | 0.15% | 0.10% | 0.015% | 0.010% |

MIM-CoNiCrMo Physics and Mechanical Properties

Status | Tensile Strength (MPa) | Yield Strength (MPa) | Impact Strength (J) | Hardness (HRC) | Young's Modulus (GPa) | Poisson's Ratio | Elongation (%) | Density (g/cm³) |

|---|---|---|---|---|---|---|---|---|

As Sintered | 800 | 700 | 20 | 45 | 220 | 0.3 | 10 | 8.5 |

MIM-CoNiCrMo Injection Molded Applications

MIM-CoNiCrMo injection-molded Turbine Components

MIM-CoNiCrMo injection-molded turbine components exhibit exceptional high-temperature resistance, making them ideal for gas and steam turbines. They can withstand the heat generated during power generation, maintaining their structural integrity and mechanical properties.

CoNiCrMo turbine components possess outstanding corrosion resistance, a vital attribute in the harsh operating conditions of turbines. Whether in power generation or aerospace applications, these components endure exposure to moisture and aggressive gases. Their corrosion resistance ensures the integrity of critical turbine parts, preventing degradation and enhancing these systems' overall safety and reliability.

MIM-CoNiCrMo Injection molding Valve and Pump Components

MIM-CoNiCrMo injection-molded valve and pump components provide many benefits. These components exhibit exceptional resistance to corrosion and wear. CoNiCrMo components maintain their structural integrity, ensuring long-term reliability and reduced maintenance costs in industries where aggressive fluids, abrasive particles, or corrosive chemicals are commonplace.

The precision achievable through the injection molding allows for intricate and complex geometries in the CoNiCrMo valve and pump components. This precision ensures a tight and consistent fit within the valve and pump assemblies, minimizing the risk of leaks and optimizing flow control. Moreover, CoNiCrMo's mechanical strength enables the creation of robust and durable components that can withstand the demanding conditions often encountered in industrial fluid handling applications.

MIM-CoNiCrMo MIM sintering Heat Exchanger Components

MIM-CoNiCrMo MIM sintering heat exchanger components offer a range of benefits that significantly enhance their performance in various heat exchange applications. Firstly, these components' corrosion resistance is ideal for heat exchanger systems where exposure to aggressive chemicals and elevated temperatures is expected. CoNiCrMo components resist corrosion effectively, ensuring the long-term integrity of the heat exchanger, reducing maintenance costs, and extending its operational life.

Secondly, CoNiCrMo heat exchanger components are known for their exceptional heat transfer efficiency. The precise manufacturing capabilities of the MIM process allow for intricate and finely detailed geometries, optimizing heat transfer within the exchanger. This efficiency contributes to energy savings and improved overall system performance. Additionally, CoNiCrMo's mechanical strength ensures the durability of these components, even in high-temperature environments.

MIM-CoNiCrMo Metal Injected Oil and Gas Exploration Components

MIM-CoNiCrMo metal-injected components for oil and gas exploration applications offer a range of crucial benefits that enhance their performance and durability in demanding environments. Firstly, these components exhibit exceptional corrosion resistance, a vital attribute when dealing with corrosive substances in oil and gas exploration. CoNiCrMo components withstand exposure to harsh chemicals and high-pressure conditions while maintaining their structural integrity, whether used in drilling tools or downhole equipment.

Secondly, CoNiCrMo components provide superior mechanical strength and wear resistance. In the rigorous conditions of drilling and exploration, these components endure high stress, abrasive environments, and extreme temperatures. Their wear resilience ensures critical equipment's longevity, reducing the need for frequent replacements and enhancing operational efficiency.

Consultative Design Services

Neway Custom Metal Injection Molding Service provides free Consultative Design Services throughout the process. It includes all processes from your design stage to mass-produced finished products.

1. Material selection Consult

2. Structural design service

3. Mold design service

Contact us now if you are interested.

Industry Solution Case Study

Custom parts manufacturing is crucial across diverse industries, and Neway excels in meeting their unique demands. Neway mainly provides customized parts in Aerospace, Medical Devices, Automotive, Telecommunication, Consumer Electronics, Lighting, E-Mobility, Power Tools, Energy, and Locking System Parts Manufacturing. Neway's precision and versatility make it a top choice for custom parts manufacturing across these industries, aligning seamlessly with their specific needs.

MIIM FAQs

1. What is metal injection molding used for?

2. What are the factors affecting the tolerance of MIM parts?

3. Which materials are suitable for metal injection molding?