MIM-CoCrMo (ASTM F75)

MIM-CoCrMo (ASTM F75) MIM Parts Manufacturer

CoCrMo (ASTM F75) Medical Injection Molded Parts

CoCrMo (ASTM F75) injection molded parts are components made from a cobalt-based alloy that conforms to the ASTM F75 standard. This alloy is renowned for its exceptional biocompatibility, corrosion resistance, and mechanical strength, making it a preferred choice for various medical device applications.

Typical applications of CoCrMo (ASTM F75) injection molded parts:

Orthopedic Implants

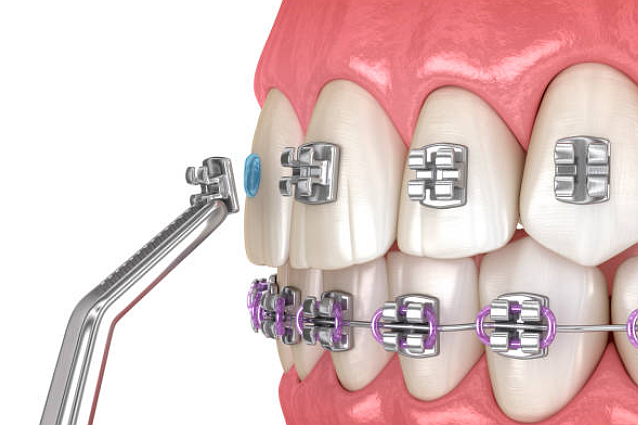

Dental Prosthetics

Surgical Instruments

Cardiovascular Devices

Spinal Implants

Typical Properties of MIM-CoCrMo (ASTM F75) Cobalt Alloy

MIM-CoCrMo (ASTM F75) Chemical Composition

Cobalt (Co) | Chromium (Cr) | Molybdenum (Mo) | Nickel (Ni) | Iron (Fe) | Manganese (Mn) | Silicon (Si) | Carbon (C) | Nitrogen (N) |

|---|---|---|---|---|---|---|---|---|

63.0% | 29.0% | 6.0% | 1.0% | 1.0% | 0.5% | 0.3% | 0.15% | 0.1% |

MIM-CoCrMo (ASTM F75) Physics and Mechanical Properties

Status | Tensile Strength (MPa) | Yield Strength (MPa) | Impact Strength (J) | Hardness (HRC) | Young's Modulus (GPa) | Poisson's Ratio | Elongation (%) | Density (g/cm³) |

|---|---|---|---|---|---|---|---|---|

As Sintered | 750 | 550 | 30 | 38 | 220 | 0.3 | 9 | 8.35 |

CoCrMo (ASTM F75) Injection Molded Applications

Injection-Molded Dental Prosthetics

CoCrMo (ASTM F75) injection-molded dental prosthetics offer many benefits, making them a preferred choice in restorative dentistry. First and foremost, these prosthetics are exceptionally biocompatible, ensuring they seamlessly integrate into the oral environment without triggering adverse reactions or allergies. This biocompatibility makes them suitable for a wide range of patients, providing a comfortable and safe solution for dental restoration.

Secondly, CoCrMo dental prosthetics exhibit remarkable durability and resistance to wear and corrosion. It is especially crucial in the demanding oral environment, where prosthetic components are subjected to mechanical stress and exposure to saliva and various substances. Their high strength and resistance to degradation ensure a prolonged lifespan for the prosthetics, reducing the need for frequent replacements.

Metal-Injected Orthopedic Implants

CoCrMo (ASTM F75) metal-injected orthopedic implants bring significant benefits to orthopedics. Firstly, these implants are renowned for their exceptional biocompatibility, making them a safe choice for implantation within the human body. This biocompatibility ensures minimal risk of adverse reactions or rejections, allowing patients to undergo orthopedic procedures confidently.

Secondly, the mechanical properties of CoCrMo (ASTM F75) are well-suited for orthopedic applications. These implants boast high tensile strength, enabling them to bear the mechanical stresses in various orthopedic procedures. Furthermore, they exhibit excellent fatigue resistance, meaning they can withstand repetitive loading without weakening or failing. Combining mechanical strength and durability makes CoCrMo implants a reliable choice for joint replacements, ensuring patients enjoy improved mobility and an enhanced quality of life.

MIM-Sintering Surgical Instruments

First and foremost, these instruments are known for their exceptional durability and corrosion resistance. In the rigorous and often corrosive environment of surgical procedures, instruments made from CoCrMo withstand repeated sterilization, exposure to bodily fluids, and mechanical stresses without degrading. This longevity reduces the need for frequent replacements, contributing to cost-effectiveness and ensuring that surgeons can rely on these instruments for critical procedures.

Secondly, CoCrMo surgical instruments provide superior precision due to their manufacturing process. Metal Injection Molding (MIM) allows for intricate and complex geometries, resulting in instruments with fine details and sharp edges. Surgeons can trust that CoCrMo MIM-sintered instruments will maintain their integrity, ensuring consistent and reliable performance throughout various medical procedures.

MIM-Sintered Cardiovascular Devices

CoCrMo (ASTM F75) MIM-sintered cardiovascular devices offer significant advantages in cardiology. First and foremost, these devices are exceptionally biocompatible, ensuring seamless integration into the cardiovascular system without causing adverse reactions or complications.

Secondly, CoCrMo cardiovascular devices demonstrate remarkable resistance to corrosion and outstanding durability, essential attributes for implantable devices in the demanding environment of the circulatory system. These devices must endure constant exposure to blood flow and mechanical stresses. CoCrMo's corrosion resistance ensures the implants' long-term performance and structural integrity, reducing the frequency of replacements and additional medical interventions. This durability enhances patient outcomes by minimizing the risk of device failure and complications, ultimately improving the quality of life for individuals with cardiovascular conditions.

What We Can Do In Metal Injection Molding?

We can provide a one-stop service from prototyping to mass production for your custom injection molded parts. this includes

4. On-Demand Manufacturing Service

5. Simple Assembly Service