MIM-52100

MIM-52100 Low Alloy Steel Metal Injection Molding service

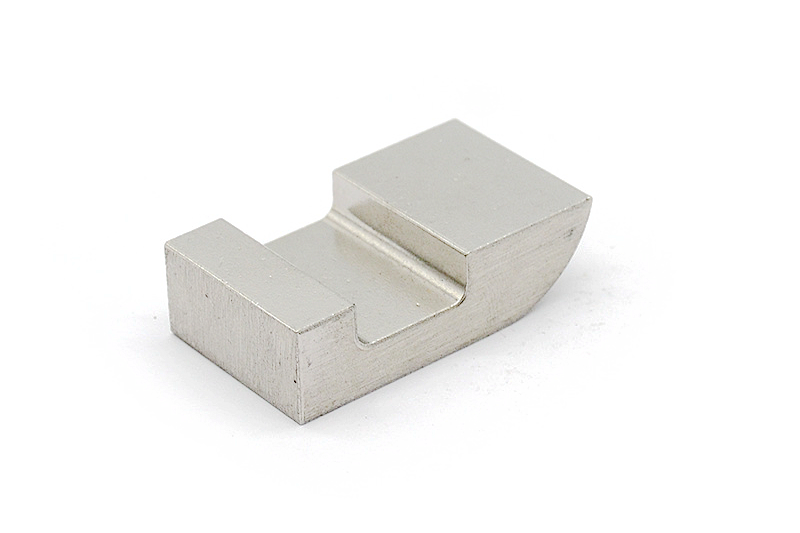

MIM-52100 is a low alloy steel commonly utilized in metal injection molding (MIM) processes. This material is renowned for its exceptional combination of properties, making it highly sought after in various industries.

MIM-52100 exhibits outstanding strength, hardness, and wear resistance, making it suitable for critical durability and longevity applications. Its fine-grained microstructure, achieved through the MIM process, contributes to precise dimensional control and enhanced mechanical properties.

This low alloy steel finds applications in sectors such as automotive, aerospace, and industrial manufacturing, where its remarkable properties benefit from components like gears, bearings, and precision parts. MIM-52100 is prized for its ability to meet demanding requirements while maintaining cost-efficiency in production, making it a preferred choice for intricate and high-performance components across various industries.

Key Features and Applications of MIM-52100

Key Features of MIM-52100 | Applications in Various Industries |

|---|---|

Exceptional Strength | Automotive |

High Hardness (HRC) | Aerospace |

Outstanding Wear Resistance | Industrial Manufacturing |

Precise Dimensional Control | Gears and Bearings |

Fine-Grained Microstructure | Precision Components |

Excellent Machinability | Tooling |

MIM-52100 Low Alloy Steel Typical Properties

MIM-52100 Chemical Composition

Alloying Element | Iron (Fe) | Chromium (Cr) | Manganese (Mn) | Carbon (C) | Silicon (Si) | Phosphorus (P) | Sulfur (S) |

|---|---|---|---|---|---|---|---|

Percentage | 97.0% | 1.4% | 0.4% | 0.1% | 0.1% | 0.02% | 0.02% |

MIM-52100 Physics and Mechanical Properties

Property | Status | Tensile Strength (MPa) | Yield Strength (MPa) | Impact Strength (J) | Hardness (HRC) | Young's Modulus (GPa) | Poisson's Ratio | Elongation (%) | Density (g/cm³) |

|---|---|---|---|---|---|---|---|---|---|

Typical Values | As-Sintered | 700 | 500 | 20 | 58 | 205 | 0.29 | 8 | 7.8 |

Other Excellent Properties of MIM-52100

Fatigue Strength

MIM-52100 parts demonstrate excellent fatigue strength, and the material can withstand cyclic loading without failure. MIM-52100's high fatigue strength ensures that parts like bearings, shafts, and gears can endure extended periods of continuous use without experiencing premature fatigue-related failures, contributing to the overall reliability and longevity of the systems in which they are employed.

Applications that demand strong fatigue resistance in MIM-52100 parts include automotive drivetrain components like wheel bearings, transmission gears, crankshafts, and aerospace components such as landing gear assemblies and turbine engines.

Magnetic Properties

MIM-52100 parts can exhibit magnetic properties depending on their specific alloy composition and processing. These properties can range from ferromagnetic (having permanent magnetism) to paramagnetic (exhibiting temporary magnetism when exposed to an external magnetic field).

Applications requiring magnetic properties in MIM-52100 parts include sensors used in automotive and industrial settings, magnetic actuators in control systems, and components in magnetic assemblies.

Corrosion Resistance

While 52100 steel is not inherently corrosion-resistant like stainless steel, it can still provide reasonable protection against corrosion when adequately maintained and shielded from corrosive environments.

Applications requiring corrosion resistance in MIM-52100 parts include automotive components like bearings and specific industrial equipment components. These parts are often exposed to moisture and varying environmental conditions, necessitating a balance between wear resistance and corrosion protection to ensure long-term functionality and reliability.

Wear Resistance

The wear resistance of MIM 52100 is primarily attributed to the steel's composition and microstructure. The fine-grained microstructure achieved through the MIM process contributes to superior hardness, making MIM-52100 highly resistant to surface wear and abrasion.

Applications that demand high wear resistance in MIM-52100 parts include automotive and aerospace components, such as engine bearings and transmission gears, and industrial machinery components like rollers and cutting tools. In these applications, MIM-52100's wear-resistant properties help extend the operational lifespan of critical components, reduce maintenance requirements, and enhance overall system efficiency.

Consultative Design Services

Neway Custom Metal Injection Molding Service provides free Consultative Design Services throughout the process. It includes all processes from your design stage to mass-produced finished products.

1. Material selection Consult

2. Structural design service

3. Mold design service

Contact us now if you are interested.

More MIM Materials Optional

Neway has a comprehensive selection of metal injection molding materials. We have a mature metal powder supply chain. At the same time, we can configure the powders according to specific MIM part requirements.

Common MIM Materials We Use: