MIM-4340

MIM 4340 Metal Injection Molding service

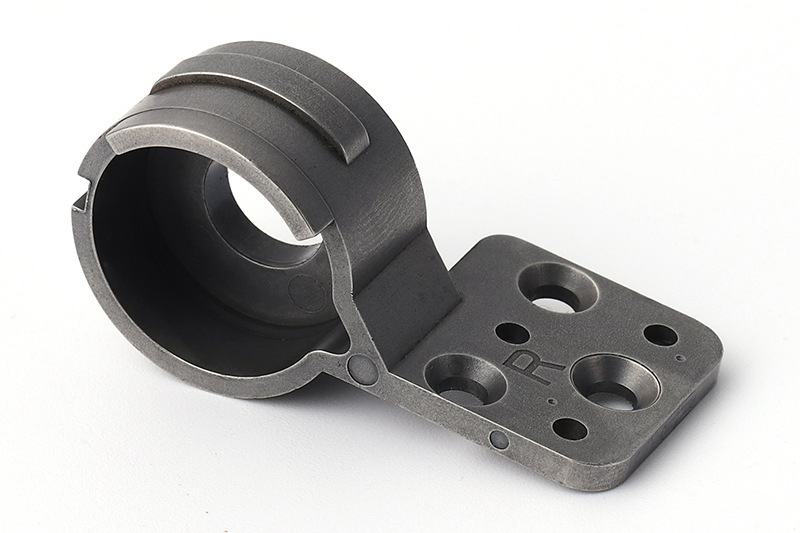

MIM 4340 Metal Injection Molded Parts

MIM-4340 is a low-alloy steel contains significant amounts of carbon, chromium, and molybdenum, contributing to its strength, hardness, and wear resistance. With a tensile strength exceeding 1100 MPa and a hardness level typically surpassing HRC 50, MIM-4340 offers robust mechanical performance, making it suitable for various demanding applications.

The versatility of MIM-4340 extends to its excellent machinability and weldability, allowing for intricate component designs and easy assembly.

4340 MIM parts find extensive use in automotive, aerospace, oil and gas, and tooling industries, where components require exceptional strength, toughness, and wear resistance. Whether in high-performance gears, critical aerospace components, or precision tooling, MIM-4340 low alloy steel is a reliable choice for challenging engineering applications.

Key Features and Applications of MIM 4340

Key Features | Applications |

|---|---|

Exceptional Strength and Hardness | Aerospace Components |

High Wear Resistance | Automotive Gears |

Excellent Toughness | Oil and Gas Equipment |

Good Machinability | Tooling and Dies |

Weldability | Industrial Machinery |

Versatility | Medical Instruments |

Corrosion Resistance | Firearm Components |

Precision Manufacturing | Consumer Electronics |

MIM 4340 Low Alloy Steel Typical Properties

MIM 4340 Chemical Composition

Element | Carbon (C) | Manganese (Mn) | Phosphorus (P) | Sulfur (S) | Silicon (Si) | Nickel (Ni) | Chromium (Cr) | Molybdenum (Mo) | Iron (Fe) |

|---|---|---|---|---|---|---|---|---|---|

Weight % | 0.38 | 0.70 | 0.02 | 0.02 | 0.25 | 1.80 | 0.80 | 0.25 | Balance |

MIM 4340 Physics and Mechanical Properties

Property | Status | Tensile Strength (MPa) | Yield Strength (MPa) | Impact Strength (J) | Hardness (HRC) | Young's Modulus (GPa) | Poisson's Ratio | Elongation (%) | Density (g/cm³) |

|---|---|---|---|---|---|---|---|---|---|

Value | Annealed | 800 | 700 | 40 | 45 | 180 | 0.28 | 10 | 7.7 |

Other Excellent Properties of MIM 4340

Machinability

MIM 4340 low alloy steel exhibits good machinability, especially in its annealed state. Combining a lower carbon content and alloying elements like chromium and molybdenum improves the machinability compared to other alloy steels. During machining processes such as turning, milling, or drilling, the material forms small, continuous chips, reducing the likelihood of tool wear and prolonging tool life.

The machinability of MIM 4340 steel is particularly advantageous in applications where post-processing or customization is essential. Examples include aerospace components, where intricate designs often necessitate additional machining for precision, and automotive parts, such as gears or shafts, that may require fine-tuning to meet specific requirements.

Weldability

MIM 4340 low alloy steel offers good weldability, particularly in the annealed or normalized condition. This attribute stems from its lower carbon content and the alloying elements that promote ease of welding. The steel can be readily welded using conventional techniques such as arc welding, MIG (Metal Inert Gas) welding, or TIG (Tungsten Inert Gas) welding.

In automotive manufacturing, components like suspension parts or shafts may need welding to assemble complex systems. Similarly, in aerospace, where precision and strength are crucial, the ability to weld MIM 4340 parts ensures the integrity of structures like landing gear or engine components, allowing for maintenance and repair of critical elements while preserving overall safety and performance.

Heat Treatment

MIM 4340 low alloy steel benefits significantly from heat treatment processes to enhance its mechanical properties. The most common heat treatments applied to MIM 4340 include annealing, normalizing, quenching, and tempering. During quenching, the part is rapidly cooled to achieve a hardened structure, followed by tempering to reduce brittleness and achieve the desired balance of hardness and toughness.

Applications necessitating heat-treated MIM 4340 parts are widespread, especially in industries demanding high-performance components. Automotive manufacturing utilizes heat-treated MIM 4340 for transmission components, axles, and crankshafts. In the oil and gas industry, heat-treated MIM 4340 parts, such as gears and shafts, are used in drilling equipment.

Dimensional Stability

MIM 4340 exhibits excellent dimensional stability due to its controlled microstructure and minimal residual stress levels. This stability ensures that the part retains its intended shape and size, even after undergoing the complex metal injection molding and subsequent heat treatments. The absence of significant distortion, warping, or shape alterations makes MIM 4340 suitable for applications demanding precise and consistent dimensions.

MIM 4340's dimensional stability in the automotive industry is crucial for parts like transmission gears, ensuring smooth and efficient power transmission. Additionally, the electronics industry utilizes this property for connectors and housings to guarantee consistent, reliable connections in various electronic devices.

What We Can Do In Metal Injection Molding?

We can provide a one-stop service from prototyping to mass production for your custom injection molded parts. this includes

4. On-Demand Manufacturing Service

5. Simple Assembly Service

More MIM Materials Optional

Neway has a comprehensive selection of metal injection molding materials. We have a mature metal powder supply chain. At the same time, we can configure the powders according to specific MIM part requirements.

Common MIM Materials We Use: