MIM-2200

MIM-2200 Metal Injection Molding service

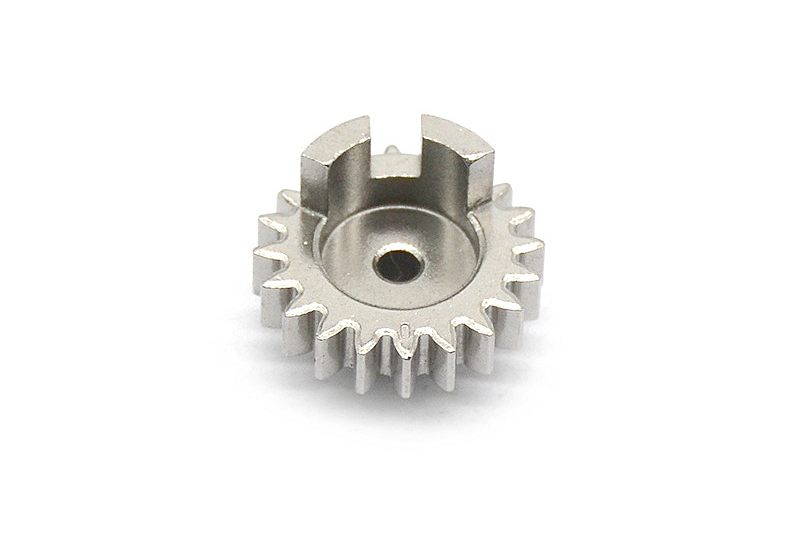

MIM-2200 is a low alloy steel designed explicitly for Metal Injection Molding (MIM) processes. This versatile material is known for its excellent mechanical properties and corrosion resistance combination. Composed primarily of iron (Fe) with alloying elements such as chromium (Cr), nickel (Ni), and molybdenum (Mo), MIM-2200 offers a balance of strength and toughness.

With a typical composition of around 1.5% nickel, 0.8% chromium, and 0.2% molybdenum, MIM-2200 exhibits good corrosion resistance, making it suitable for various environments, including mildly corrosive ones. Its low carbon content contributes to weldability and machinability.

The MIM process allows for intricate and complex shapes, making MIM-2200 a preferred choice for components where a combination of mechanical performance and intricate designs is essential. Applications for MIM-2200 range from automotive parts to firearms components, providing durability and precision in various industries.

Low Alloy Steel Neway Use:

Key Features and Applications of MIM-2200

Key Features of MIM-2200 | Applications in Various Industries |

|---|---|

High Density (7.8 g/cm³) | Consumer Electronics |

Excellent Corrosion Resistance | E-Mobility |

Precise Dimensional Control | Energy |

Complex Geometries | Medical Devices |

Fine Surface Finish | Telecommunication |

Outstanding Strength | Lighting Solutions |

Tight Tolerances | Power Tools |

Cost-Effective Production | Locking Systems |

MIM-2200 Low Alloy Steel Typical Properties

MIM-2200 Chemical Composition

Alloying Element | Iron (Fe) | Nickel (Ni) | Molybdenum (Mo) | Copper (Cu) | Carbon (C) | Other Elements |

|---|---|---|---|---|---|---|

Percentage | 74.5% | 22.0% | 2.0% | 0.5% | 0.1% | 0.9% |

MIM-2200 Physics and Mechanical Properties

Property | Status | Tensile Strength (MPa) | Yield Strength (MPa) | Impact Strength (J) | Hardness (HRC) | Young's Modulus (GPa) | Poisson's Ratio | Elongation (%) | Density (g/cm³) |

|---|---|---|---|---|---|---|---|---|---|

Typical Values | Heat Treated | 600 | 400 | 15 | 50 | 200 | 0.29 | 10 | 7.8 |

Other Excellent Properties of MIM-2200

Weldability

MIM-2200 parts exhibit good weldability, making them suitable for applications where component assembly, repair, or modification through welding processes is necessary. This material can be welded using standard techniques like TIG (Tungsten Inert Gas) welding and laser welding, ensuring robust and reliable joints.

The excellent weldability of MIM-2200 extends its utility to industries such as automotive, aerospace, and manufacturing, where components often require welding to assemble intricate systems or to address maintenance and repair needs.

Manufacturing equipment and machinery often utilize MIM-2200 parts that can be readily welded during assembly or for repairs, enhancing the longevity and flexibility of these systems.

Magnetic Properties

MIM-2200 parts can exhibit magnetic properties depending on the specific alloy composition. These magnetic properties can vary from ferromagnetic (exhibiting permanent magnetism) to paramagnetic (exhibiting temporary magnetism when exposed to an external magnetic field).

Depending on the alloy formulation, MIM-2200 components can be used in sensors, actuators, magnetic assemblies, and other applications where magnetism is a critical functional requirement.

Applications that require magnetic properties in MIM-2200 parts include sensor systems, where precise and controlled magnetic responses are needed for accurate measurements. Magnetic assemblies in industries like telecommunications and electronics also benefit from MIM-2200's magnetic characteristics.

Electrical Conductivity

MIM-2200 parts can exhibit good electrical conductivity depending on their specific alloy composition. This electrical conductivity can be advantageous in applications where the efficient flow of electrical current is required.

MIM-2200's electrical properties make it suitable for applications in electronics, power transmission, and electrical connectors, ensuring reliable conductivity and minimizing energy loss.

Applications requiring electrical conductivity in MIM-2200 parts include electrical connectors and contact components in telecommunications and consumer electronics. In power distribution and transmission systems, MIM-2200 can be utilized for various electrical contacts and components, ensuring efficient energy transfer.

Heat Resistance

MIM-2200 parts exhibit commendable heat resistance, allowing them to maintain structural integrity and performance even when exposed to elevated temperatures. Depending on specific processing and heat treatment, MIM-2200 can withstand temperatures well above 300°C (572°F).

Applications necessitating heat resistance in MIM-2200 parts include automotive exhaust system components, which must endure high temperatures without deformation or degradation.

In aerospace, MIM-2200 can be used for components within engines and propulsion systems that encounter extreme heat during operation.

MIM FAQs

1. What is metal injection molding used for?

2. What are the factors affecting the tolerance of MIM parts?

3. Which materials are suitable for metal injection molding?

4. What Is The Shrinkage of Metal Injection Molding?

Case Study: