Haynes 188

Basic description of Haynes 188 Powder

Haynes 188 powder is a cobalt-based alloy known for its excellent high-temperature strength and corrosion resistance. The alloy is composed of nickel, chromium, and tungsten, which contribute to its remarkable stability and durability under extreme thermal environments. Haynes 188 is specifically engineered for powder metallurgy and additive manufacturing processes, offering a fine powder size that ensures high packing density and uniformity in the sintered parts. This material is particularly valued for its ability to retain strength and resist oxidation at temperatures up to 1095°C (2000°F), making it an excellent choice for applications in aerospace, power generation, and industrial heating.

Haynes 188 Similar grades

China: GH5188

United States: R30188

Germany: W.Nr.2.4683

France: KCN22W

While Haynes 188 is unique in its composition and properties, there are other alloys with similar high-temperature capabilities used in demanding environments:

Haynes 230: Offers superior high-temperature strength, oxidation resistance, and long-term stability up to 1149°C (2100°F), making it suitable for furnace components and gas turbine applications.

Inconel 718: A nickel-chromium alloy known for its high strength, corrosion resistance, and flexibility at high temperatures, widely used in the aerospace and energy sectors.

Rene 41: A nickel-based superalloy with excellent strength and oxidation resistance at temperatures up to around 980°C (1800°F), commonly used in aircraft engines and turbine blades.

Waspaloy: A nickel-cobalt-chromium-molybdenum alloy with high strength and stability up to 870°C (1600°F), often employed in gas turbine parts and aerospace fasteners.

Each of these alloys serves specific industrial needs, with Haynes 188 being the preferred choice for applications requiring exceptional high-temperature strength and corrosion resistance, combined with the advantages of powder metallurgy and additive manufacturing techniques.

Applications

The unique properties of Haynes 188 powder, including its excellent high-temperature strength, corrosion resistance, and stability, make it highly suitable for various critical applications across different industries. Here's a closer look at specific applications where Haynes 188 powder is particularly beneficial:

1. Aerospace: Haynes 188 is extensively used in the aerospace industry for manufacturing components that must withstand extreme temperatures and corrosive environments. Applications include turbine engines, combustion chambers, and afterburner parts. The alloy's resistance to oxidation and thermal fatigue ensures the reliability and longevity of aerospace components.

2. Power Generation: In power plants, especially those involving gas turbines, Haynes 188 fabricates burner cans, transition ducts, and other high-temperature components. Its excellent high-temperature strength and resistance to sulfidation make it ideal for environments where fuel combustion generates corrosive by-products.

3. Industrial Heating: For industrial furnaces and kilns, Haynes 188 is chosen for burner nozzles, flame holders, and other components exposed to high temperatures and cyclic thermal stresses. The alloy's thermal stability contributes to enhanced furnace performance and efficiency.

4. Chemical Processing: The resistance of Haynes 188 to a wide range of chemical environments makes it suitable for reactor vessels, heat exchangers, and piping in chemical processing plants. Its corrosion resistance is precious in corrosive chemical processes at high temperatures.

5. Gas Turbine Components: Beyond power generation, Haynes 188 manufactures critical gas turbine components, including blades, vanes, and combustion liners. These applications benefit from the alloy's resistance to high-temperature corrosion and its ability to maintain mechanical properties at elevated temperatures.

6. Exhaust Systems: In automotive and aerospace applications, Haynes 188 is employed in exhaust systems and components that must resist thermal oxidation and degradation. Its ability to withstand fluctuating temperatures while maintaining structural integrity makes it an excellent choice for high-performance exhaust systems.

7. Weld Overlay and Cladding: For components requiring surface protection against wear and corrosion, Haynes 188 powder is used in weld overlay and cladding processes. This application uses the alloy's excellent weldability and compatibility with various substrates, providing enhanced surface properties without compromising the part's overall performance.

Haynes 188 Composition and Properties

Haynes 188, recognized for its exceptional performance in high-temperature environments, owes its capabilities to a carefully balanced chemical composition that imparts high-temperature strength, excellent oxidation resistance, and good corrosion resistance. Understanding the composition and resultant properties of Haynes 188 is crucial for engineers and manufacturers selecting materials for demanding applications.

Composition:

The primary constituents of Haynes 188 include:

Cobalt (Co): The base element provides excellent high-temperature strength and stability.

Chromium (Cr): Around 22% contributes significantly to oxidation resistance and helps form a protective oxide layer on the material's surface.

Nickel (Ni): Approximately 22% enhances the alloy's overall corrosion resistance and facilitates good weldability.

Tungsten (W): About 14% increases the alloy's strength and resistance to high-temperature creep.

Iron (Fe): Present in smaller amounts, typically less than 3%, to enhance the alloy's mechanical properties.

Carbon (C): A controlled amount of 0.05-0.15% helps form carbides, strengthening the alloy at high temperatures.

Other elements: Small quantities of lanthanum (La) and a few other elements may be added to refine the alloy's properties, improving its performance in specific applications.

Cr

Mn

Ni

V

Fe

C

P

Si

S

B

Mo

La

Co

≤24.00

≤1.25

≤58

13.0-16.0

≤3.00

≤0.1

≤0.02

≤0.5

≤0.015

≤0.015

≤6.5

0.02-0.15

Bal.

Properties:

This unique composition endows Haynes 188 with a set of properties tailored for extreme conditions:

High-Temperature Strength: Haynes 188 maintains its strength and stability at temperatures up to 1095°C (2000°F), making it ideal for high thermal loads applications.

Oxidation Resistance: The chromium content provides excellent resistance to oxidation, which is crucial for components exposed to air or other oxidizing environments at high temperatures.

Corrosion Resistance: With nickel and chromium as significant components, the alloy exhibits good resistance to corrosive environments, including those encountered in chemical processing and aerospace applications.

Creep Resistance: Adding tungsten significantly enhances the alloy's resistance to creep, ensuring the material's integrity under sustained high-temperature stress.

Weldability: Despite its high strength, Haynes 188 can be welded with conventional welding techniques, offering flexibility in manufacturing complex components.

Applications Stemming from Composition and Properties:

The balanced composition of Haynes 188, resulting in its exceptional high-temperature strength, oxidation, and corrosion resistance, makes it suitable for various demanding applications. These include turbine engine parts, combustion chambers, and heat-treating equipment, where durability and performance at elevated temperatures are critical. The alloy's properties also make it a preferred choice for fabricating components in chemical processing environments requiring resistance to corrosive substances. By leveraging these attributes, Haynes 188 enables the development of components that perform reliably in some of the most challenging industrial conditions.

Haynes 188 Powder Characteristics

The powder form of Haynes 188 is engineered to support advanced manufacturing techniques, notably additive manufacturing (3D printing), Metal Injection Molding (MIM), and Powder Compression Molding (PCM). Understanding the specific characteristics of Haynes 188 powder is essential for optimizing manufacturing processes and achieving high-quality parts with desired mechanical properties.

Yield Strength:

Yield strength is a critical mechanical property that signifies the stress at which a material begins to deform plastically. Haynes 188 parts, processed under optimal conditions, can exhibit yield strengths in the 45,000 to 65,000 psi range. This high yield strength underlines the material's suitability for applications where components are subjected to high stress and temperatures.

Tensile Strength:

Tensile strength represents the maximum stress a material can withstand while being stretched or pulled before failing. Haynes 188 manufactured parts can achieve tensile strengths of approximately 140,000 psi. This property is significant for aerospace and power generation applications, where materials must endure extreme operational conditions without compromising their structural integrity.

Elongation:

Elongation measures the flexibility of a material or how much it can stretch before it breaks. Manufactured parts from Haynes 188 typically show an elongation range of 40% to 50%, indicating good elasticity. This allows for some degree of flexibility and deformation under stress without leading to part failure, ensuring reliability and safety in its applications.

Physical Properties

The physical properties of Haynes 188 powder are fundamental to its application in manufacturing, especially when employing advanced techniques like additive manufacturing (3D printing), Metal Injection Molding (MIM), and Powder Compression Molding (PCM). These properties influence the behavior of the powder during processing and the performance of the final part in its operational environment.

Density:

The density of Haynes 188 is approximately 8.22 g/cm³. This high density indicates the material's compact atomic structure, contributing to the overall strength and durability of manufactured parts. Achieving near-full density in parts is critical for applications requiring high mechanical integrity and resistance to high-temperature creep.

Hardness:

Manufactured parts from Haynes 188 can achieve hardness levels up to 30 HRC (Rockwell Hardness). This hardness level balances strength and ductility, making it suitable for components exposed to wear and high-stress conditions, such as aerospace turbine blades and industrial furnace parts.

Specific Surface Area:

A higher specific surface area in the powder improves the sinterability, which is crucial for processes like MIM and additive manufacturing. The specific surface area of Haynes 188 powder is tailored to enhance the binding and sintering processes, resulting in parts with high mechanical properties and minimal porosity.

Sphericity:

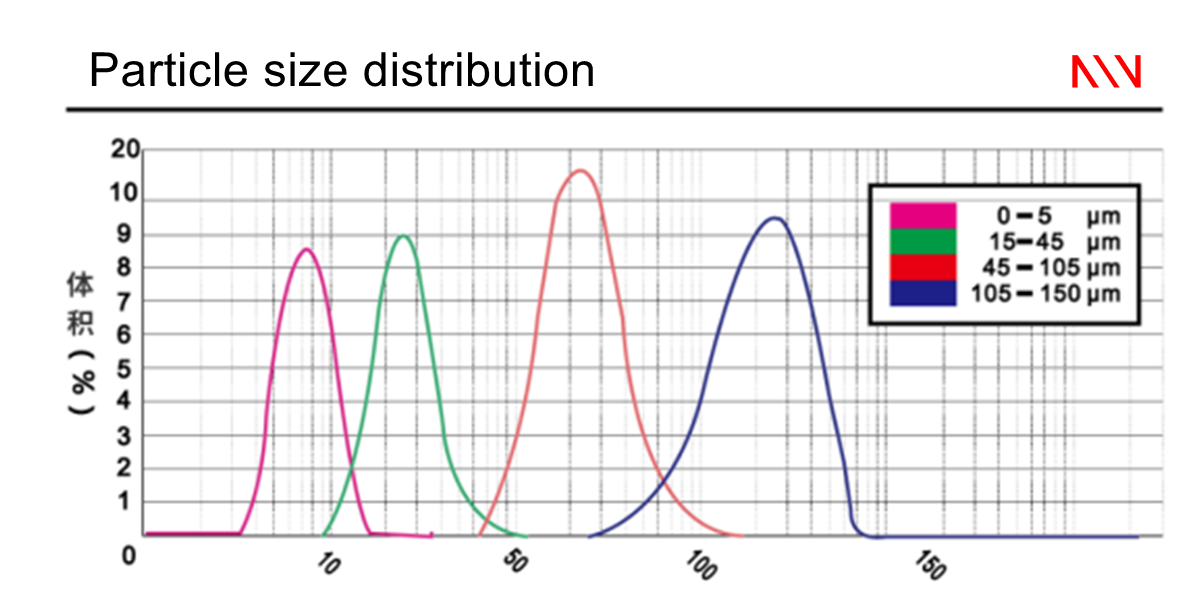

The sphericity of Haynes 188 powder impacts its flowability and packing density, essential factors for manufacturing accuracy and repeatability. High sphericity ensures uniform flow and layering in additive manufacturing processes, contributing to the final parts' dimensional accuracy and surface finish.

Bulk Density:

The bulk density of the powder influences the efficiency of powder handling and the quality of the final part. Haynes 188 powder features an optimized bulk density that facilitates easy handling and efficient compaction, essential for achieving uniform part density and strength.

Hall Flow Rate:

This property measures the powder's ability to flow through an orifice, affecting the precision of powder-based manufacturing processes. Haynes 188 powder exhibits excellent flow characteristics, enabling accurate and consistent part fabrication.

Melting Point:

Haynes 188 has a melting point suitable for the specific manufacturing processes it undergoes, typically around 1300°C to 1330°C (2372°F to 2426°F). This melting point ensures the alloy's stability and integrity during high-temperature applications.

Relative Density:

After processing, the relative density of parts can reach near theoretical density, which is crucial for achieving optimal mechanical strength and minimizing porosity, enhancing the component's performance in demanding environments.

Recommended Layer Thickness:

For additive manufacturing processes, the recommended layer thickness for Haynes 188 powder ranges to balance resolution with build time efficiently. It ensures parts with fine detail without compromising structural integrity.

Thermal Expansion Coefficient:

The alloy exhibits a thermal expansion coefficient that ensures compatibility with other materials in composite structures, maintaining dimensional stability across a wide temperature range.

Thermal Conductivity:

Its thermal conductivity allows for efficient heat dissipation, essential for components that experience high thermal loads during operation.

Technical Standard:

LZQB "Technical Specifications for Haynes 188 Alloy Powder Special for 3D Printing"

Haynes 188 powder and parts manufactured from it adhere to rigorous technical standards, ensuring reliability, quality, and compatibility with international manufacturing requirements.

Manufacturing Techniques

The distinctive properties of Haynes 188 powder make it particularly suitable for various advanced manufacturing techniques. Each process offers distinct benefits and is chosen based on the application's requirements. This section explores the most compatible manufacturing processes for Haynes 188, compares the outcomes of these processes, and discusses common issues and solutions.

1. Which manufacturing processes is Haynes 188 suitable for?

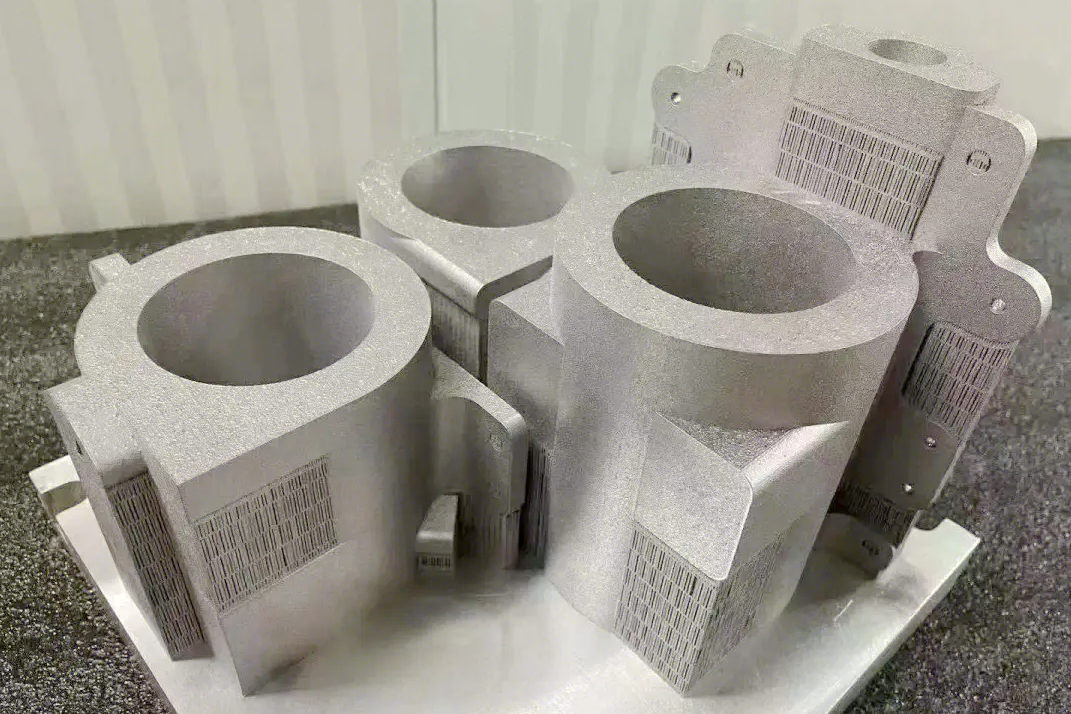

Additive Manufacturing (3D Printing): Haynes 188 powder is highly suited for laser powder bed fusion (LPBF) and direct metal laser sintering (DMLS) techniques. These processes enable the production of complex geometries and components with reduced waste, ideal for aerospace and power generation applications.

Metal Injection Molding (MIM): This process is advantageous for producing small to medium-sized complex shapes with high precision and excellent surface finish. MIM is cost-effective for high-volume production, particularly for parts requiring the unique high-temperature properties of Haynes 188.

Powder Metallurgy (PM): Traditional press and sinter techniques can be used with Haynes 188 powder to create dense, high-strength components. This method suits applications with critical uniform material properties and structural integrity.

Hot Isostatic Pressing (HIP): HIP can densify parts made from Haynes 188 powder, enhancing their mechanical properties by eliminating porosity. This process is often used in post-additive manufacturing or PM to improve the density and uniformity of parts.

2. Comparison of parts produced by these manufacturing processes:

Surface Finish and Detail Resolution: Additive manufacturing offers the ability to produce parts with complex geometries that are not possible with traditional methods but often require post-processing to achieve a smooth surface finish. MIM parts typically have an excellent surface finish and high dimensional accuracy straight out of the mold.

Mechanical Properties: Parts produced through HIP and PM can exhibit superior mechanical properties due to the homogeneous material structure and reduced porosity achieved. Additive manufacturing parts may require post-process treatments like HIP to match these levels of mechanical properties.

Cost-Effectiveness and Efficiency: MIM is particularly cost-effective for producing large quantities of complex parts, whereas additive manufacturing is more suited for low-volume, high-complexity components where traditional tooling costs are prohibitive.

3. Normal issues and solutions in these manufacturing processes:

Porosity in Additive Manufacturing: Parts produced through LPBF or DMLS may exhibit porosity, affecting mechanical properties. Solution: Optimizing process parameters (e.g., laser power, scan speed) and employing post-process treatments like HIP can significantly reduce porosity and improve part density.

Dimensional Accuracy in MIM: Shrinkage during the sintering phase can impact the dimensional accuracy of MIM parts. Solution: Design adjustments and tooling modifications can be made to compensate for shrinkage, and process optimization can help achieve the desired dimensions.

Surface Roughness in AM: Parts produced by additive manufacturing may require post-processing to achieve the desired surface quality. Solution: Techniques such as machining, polishing, or chemical etching can improve surface finish.

Manufacturing With Superalloys

Main manufacturing processes:

Nickel-based high-temperature alloys are usually used for corrosion resistance, high-temperature resistance, and other extreme working conditions, such as impellers, pump valves, auto parts, etc. Neway has a variety of processing techniques for manufacturing nickel-based high-temperature alloy parts and solving their problems, such as deformation, cracking, and porosity.

Powder compression molding (PCM)

Get A FREE PROTOTYPING SERVICE NOW!: Consultative Design Service at Neway