Small Complex Metal Parts Metal Injection Molding

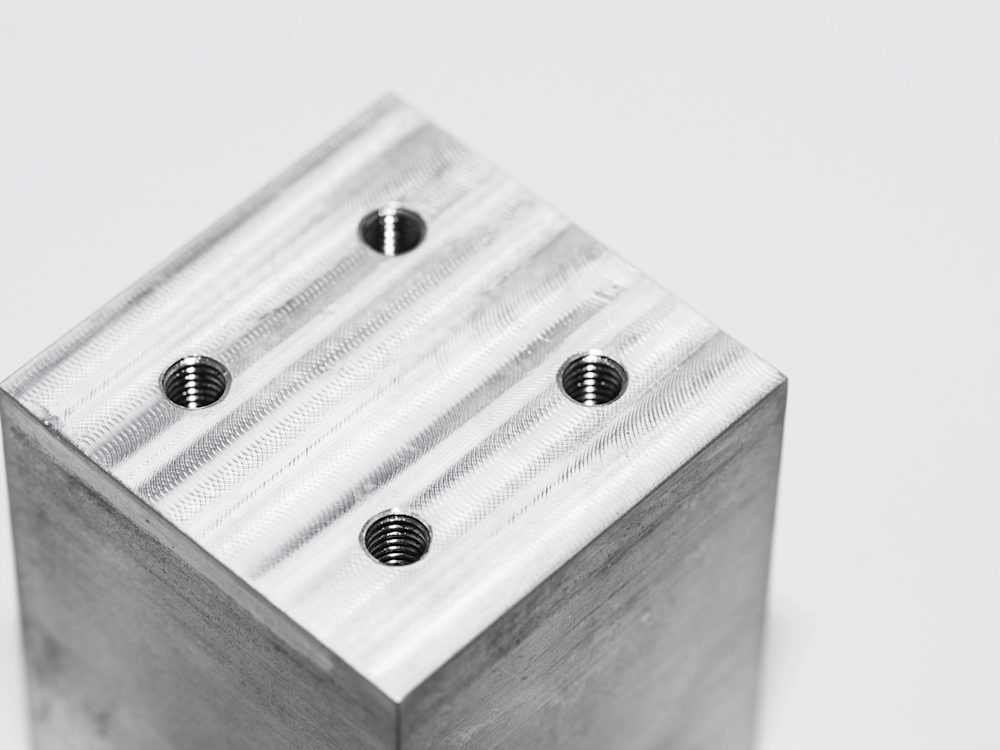

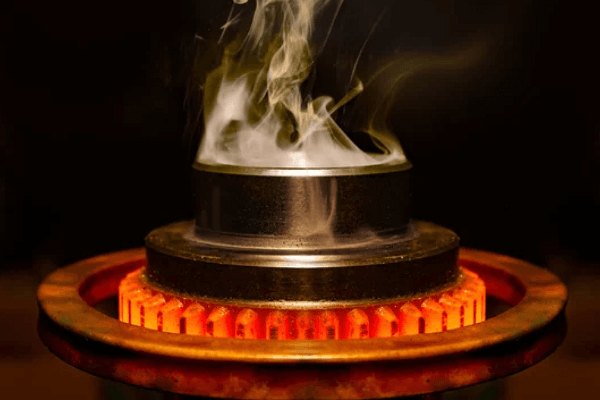

Metal injection molding combines powdered metal with a binder, injects it into molds, then heats it to remove the binder and sinter it into a durable part. Suitable for small, complex, high-precision metal parts manufacturing. The material selection range is wide, such as iron-based, nickel alloy, tungsten alloy, titanium alloy, superalloy alloy, etc.

Start Your MIM Parts Quote

All uploaded files are secure and confidential

What Is Metal Injection Molding Service

Our metal injection molding Service specializes in transforming metal powders into complex parts and components. We offer multi metal powder injection molding molding process. Such as iron base, tungsten, titanium, magnetic, and cobalt alloys injection molding. We produce high precision and strong custom MIM parts.

MIM Vs. PCM

Metal Injection Molding (MIM) and Powder Compression Molding (PCM) are distinct manufacturing processes. MIM uses fine metal powders for high-precision, complex parts, while PCM compresses powder into simpler shapes with lower precision. MIM is costlier and suited for medium to high volume production, whereas PCM is more economical for lower volumes.

Metal Injected Parts Applications

Our metal injection molding process produces high-quality parts with intricate details and superior strength. These metal injected parts find extensive use across various industries, offering precision and versatility for critical applications.

Metal Injection Molding (MIM) Materials

View How Metal Injection Molding Works

Metal injection molding is a net shape process that combines the advantages of plastic injection molding and powder metallurgy to produce highly complex metal parts and heavy alloy parts, such as stainless steel, titanium alloy, tungsten alloy, etc.

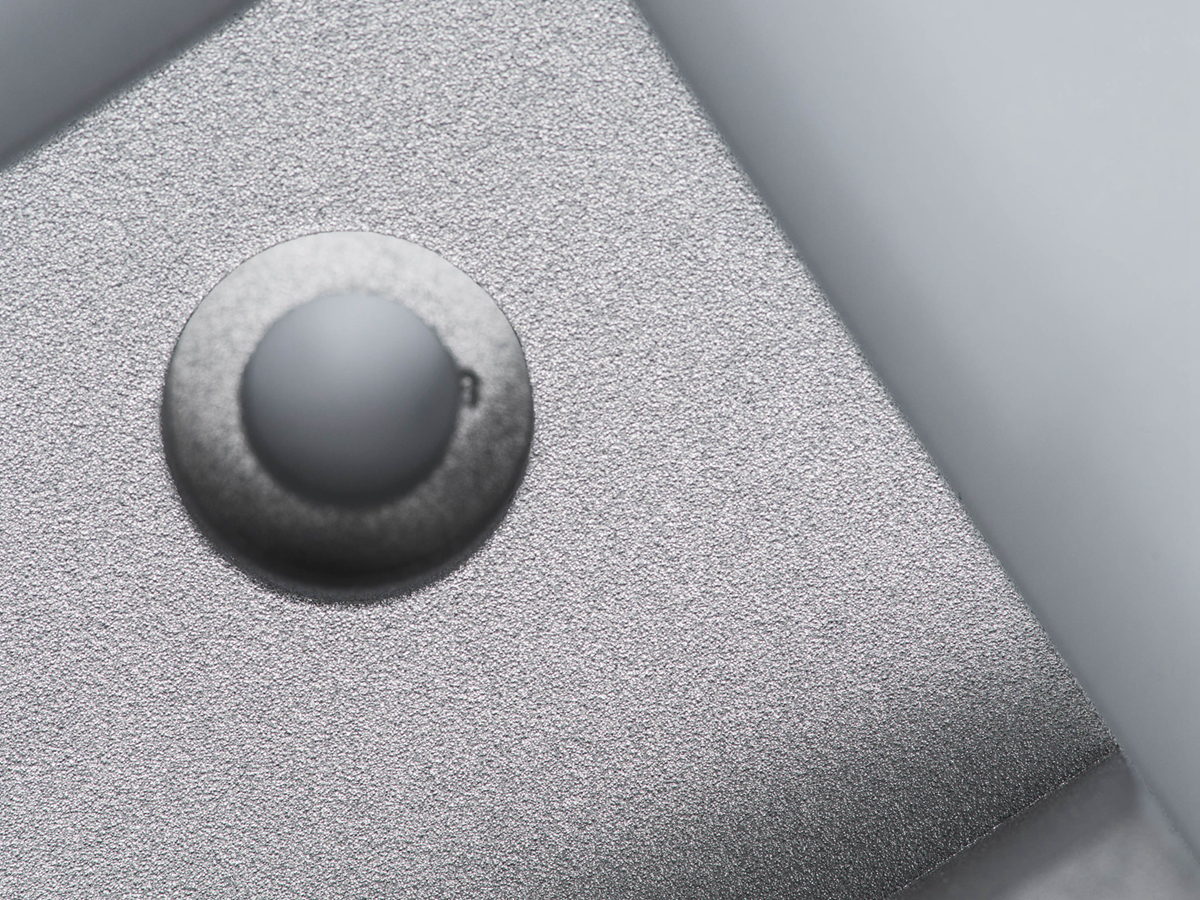

Custom Parts Surface Finishing Available

Our Surface Treatment Service offers specialized finishes for custom parts, enhancing durability, aesthetics, and performance. We provide a range of processes, including Electroplating, Anodizing, Powder Coating, and Thermal Barrier Coatings, tailored to improve corrosion resistance, wear properties, and visual appeal of metal and plastic components across industries.

learn more

As Machined

learn more

Painting

learn more

PVD

learn more

Sandblasting

learn more

Electroplating

learn more

Polishing

learn more

Anodizing

learn more

Powder Coating

learn more

Electropolishing

learn more

IMD

learn more

Brushed Finishes

learn more

Black Oxide

learn more

Heat Treatment

learn more

Tumbling

learn more

Alodine

learn more

Chrome Plating

learn more

Phosphating

learn more

Nitriding

learn more

Galvanizing

learn more

Lacquer Coating

learn more

Teflon Coating

learn more

Thermal Coatings

learn more

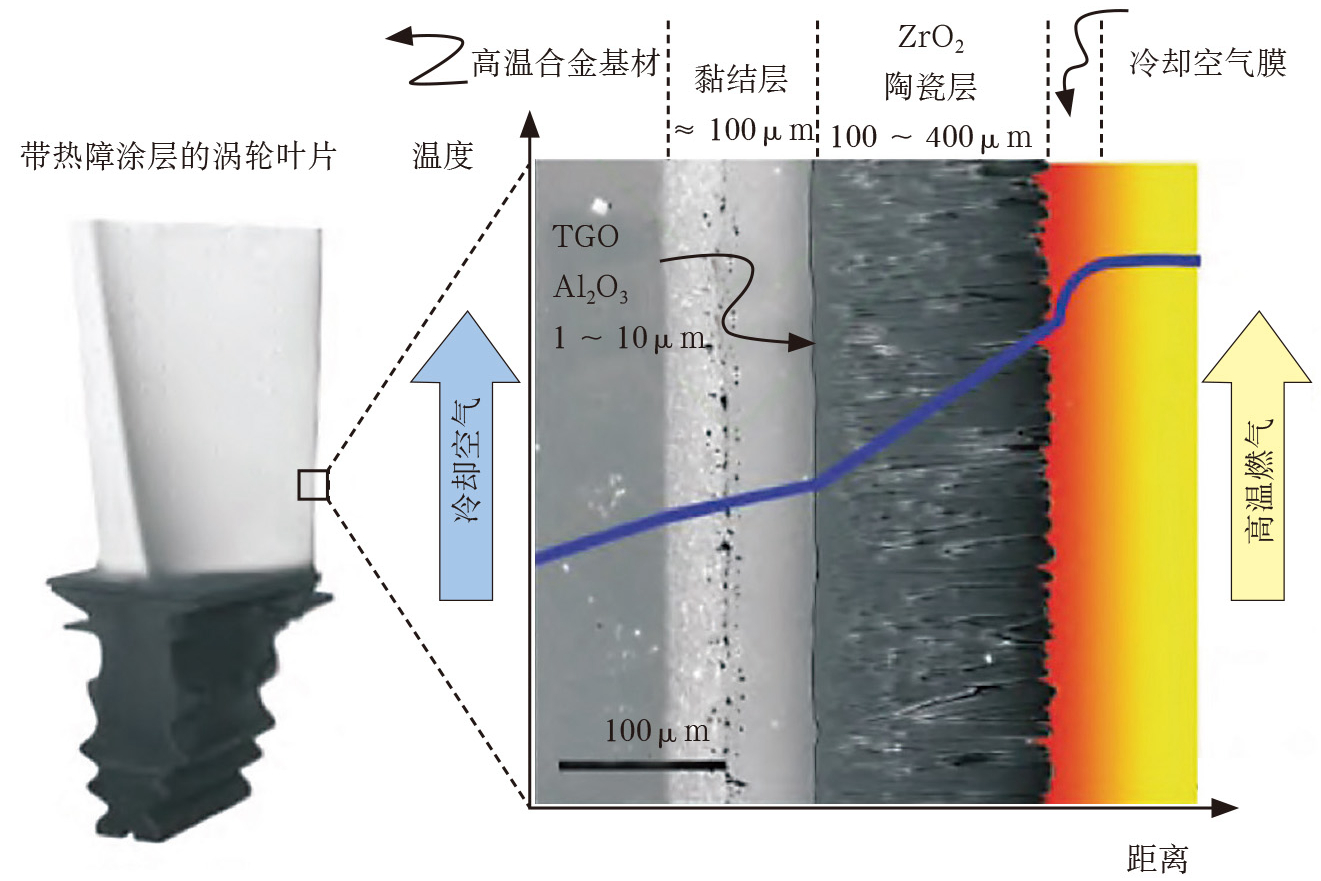

Thermal Barrier Coatings

learn more

Passivation

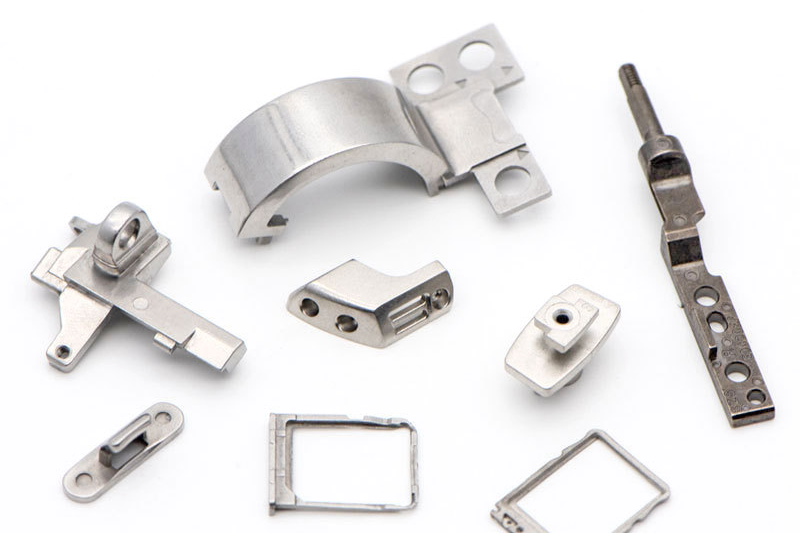

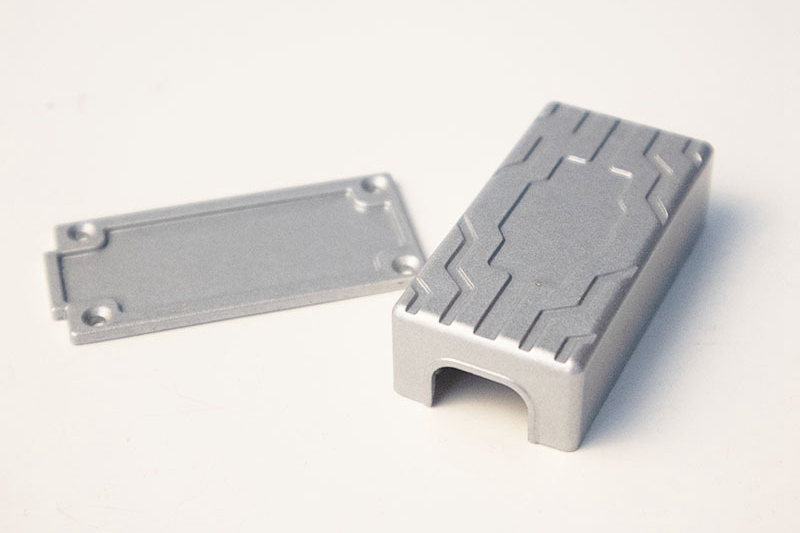

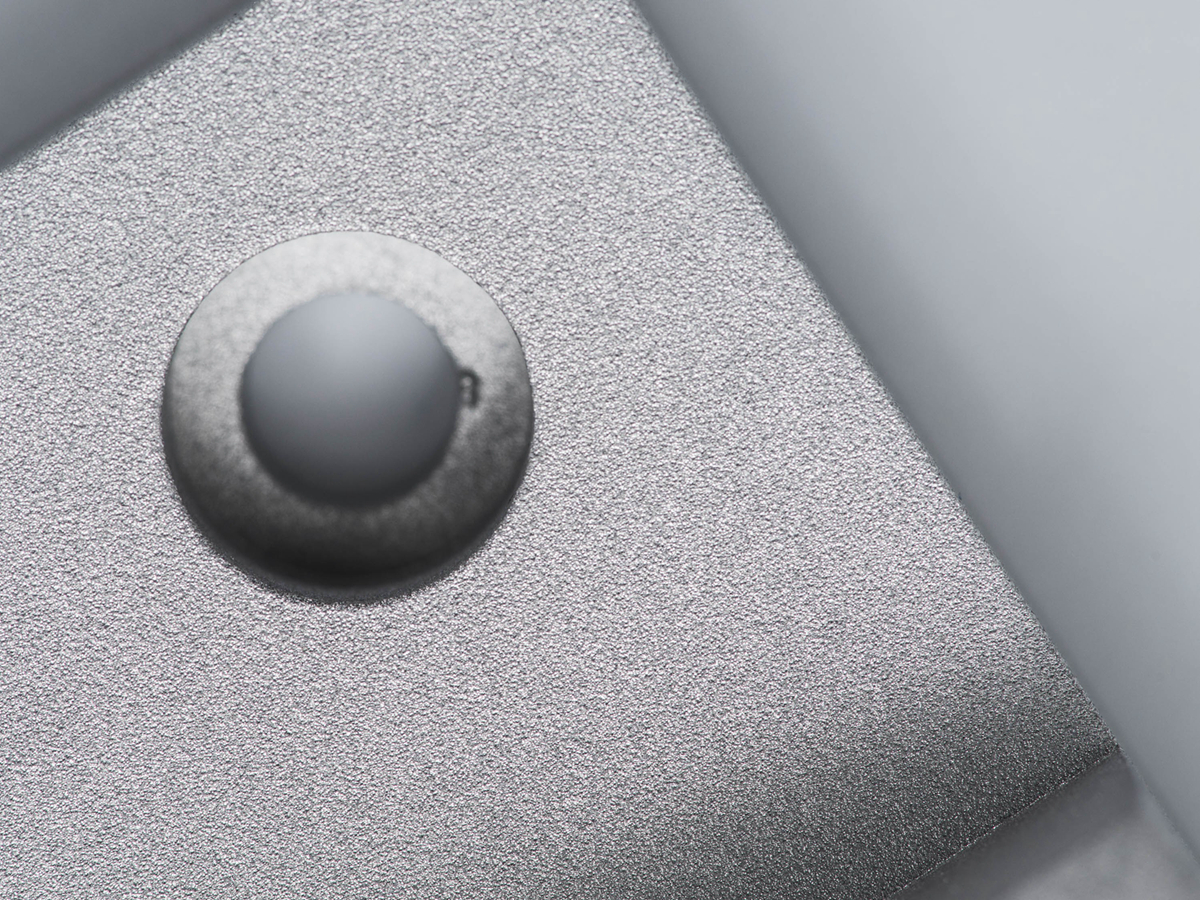

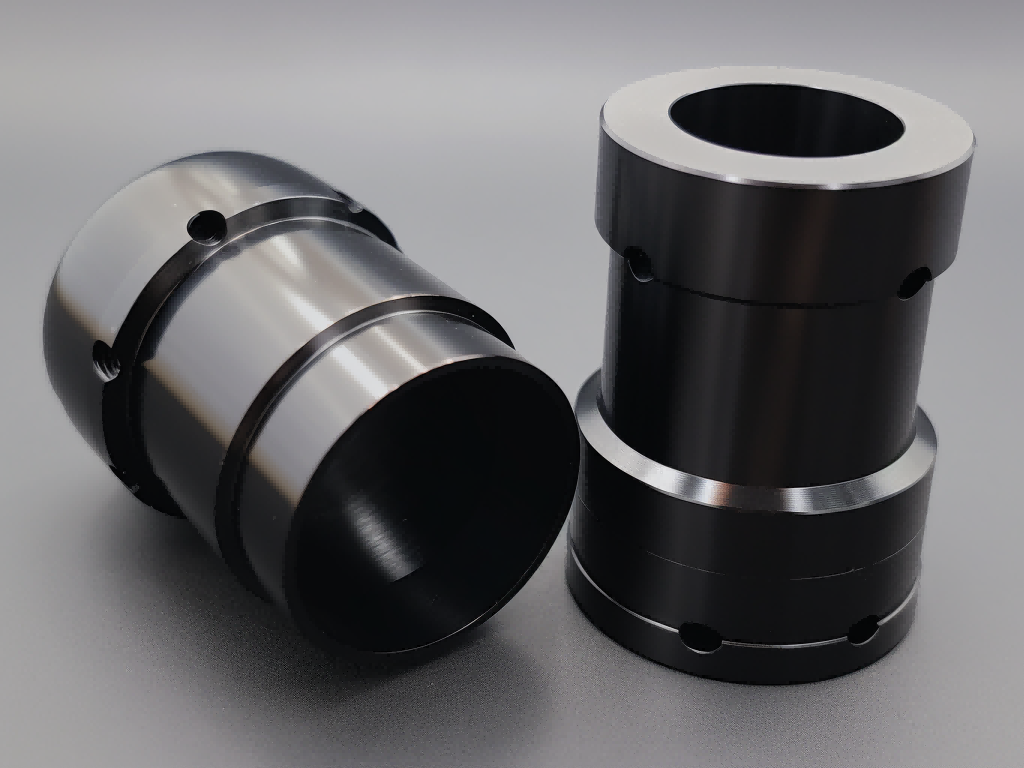

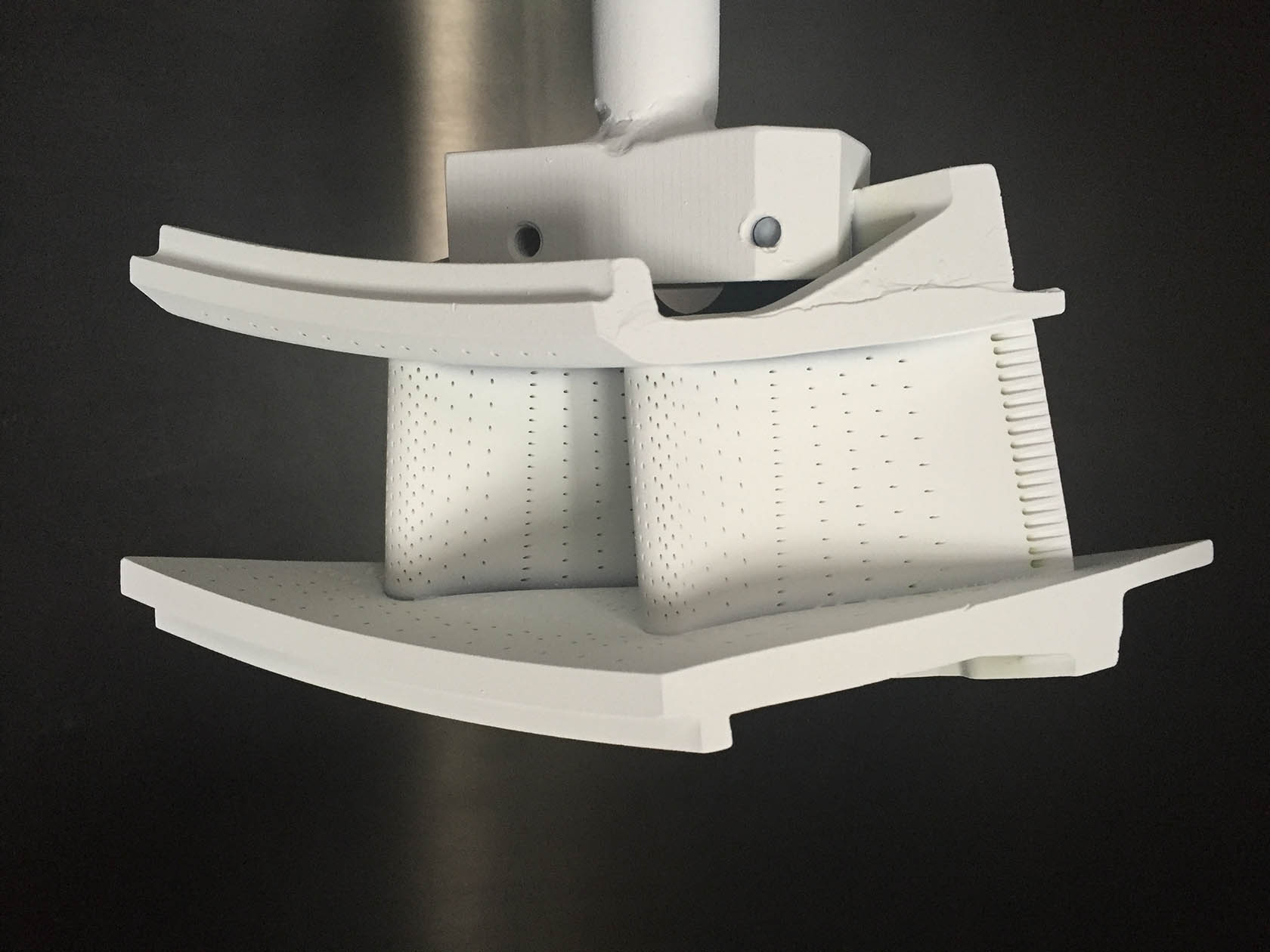

MIM Parts Gallery

At our MIM parts gallery, we understand that every project is unique. That's why we work closely with our customers to ensure that their custom parts are designed to meet their exact specifications. With our attention to detail and commitment to quality, you can trust that your custom parts will exceed your expectations.

Let's Start A New Project Today

MIM Parts Design Suggestion

Better understand the process limits of metal injection molding, such as limit size, tolerance, wall thickness, most efficient customization quantity, etc. Provide reference and save costs for your MIM part design.

Frequently Asked Questions

Explore Related Resources

Solutions

Copyright © 2025 Neway Precision Works Ltd.All Rights Reserved.