Custom Online Precision Investment Casting Service

Precision investment cast solutions tailored to your needs. Experience exceptional quality, diverse material options, and reliable expertise for all your casting requirements.

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

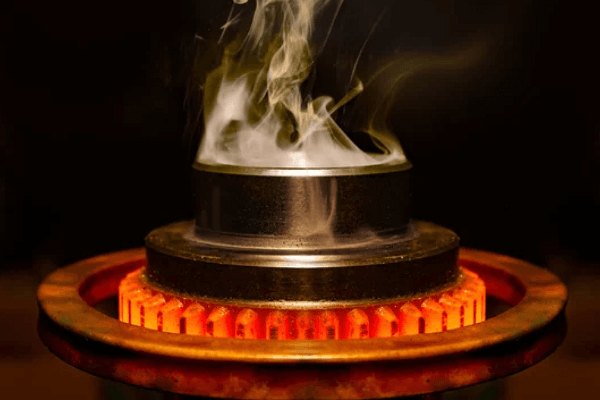

What Is Investment Casting Service

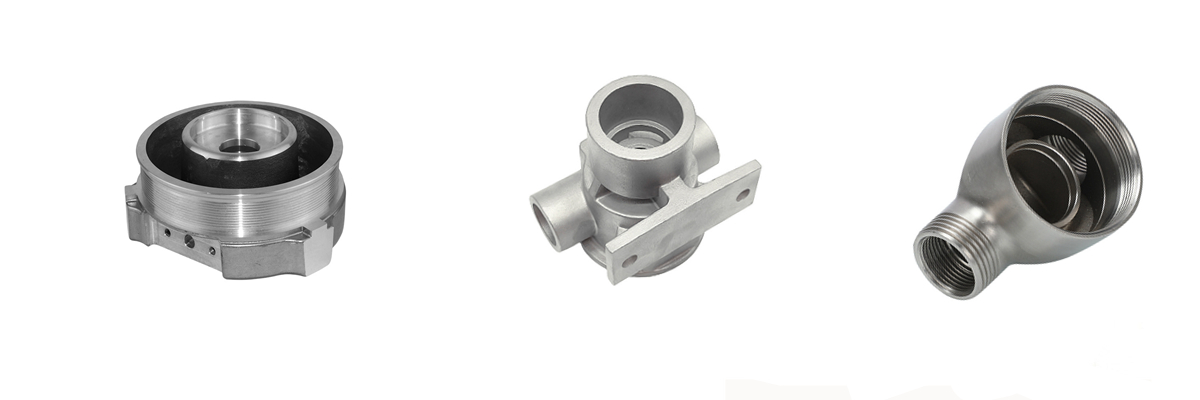

Our Investment Casting Service delivers high-quality, cost-effective metal components through a precision process that produces parts with excellent dimensional accuracy and superior surface finish. Ideal for aerospace, automotive, and industrial applications, our process ensures consistent, high-performance results.

Applications of Investment Castings

Investment castings offer unparalleled precision and intricate detail in manufacturing, delivering complex components for high-performance applications across diverse industries. Explore our range of high-quality investment casted parts.

Investment Casting Materials

Neway Custom Investment Casting Service Capabilities

Neway specialized in custom investment casting services for over 30 years. Typically Neway offers a range of capabilities to meet the needs of different industries and applications. Some of the most common capabilities include:Material Selection, Size and Complexity, Surface Finish

Custom Parts Surface Finishing Available

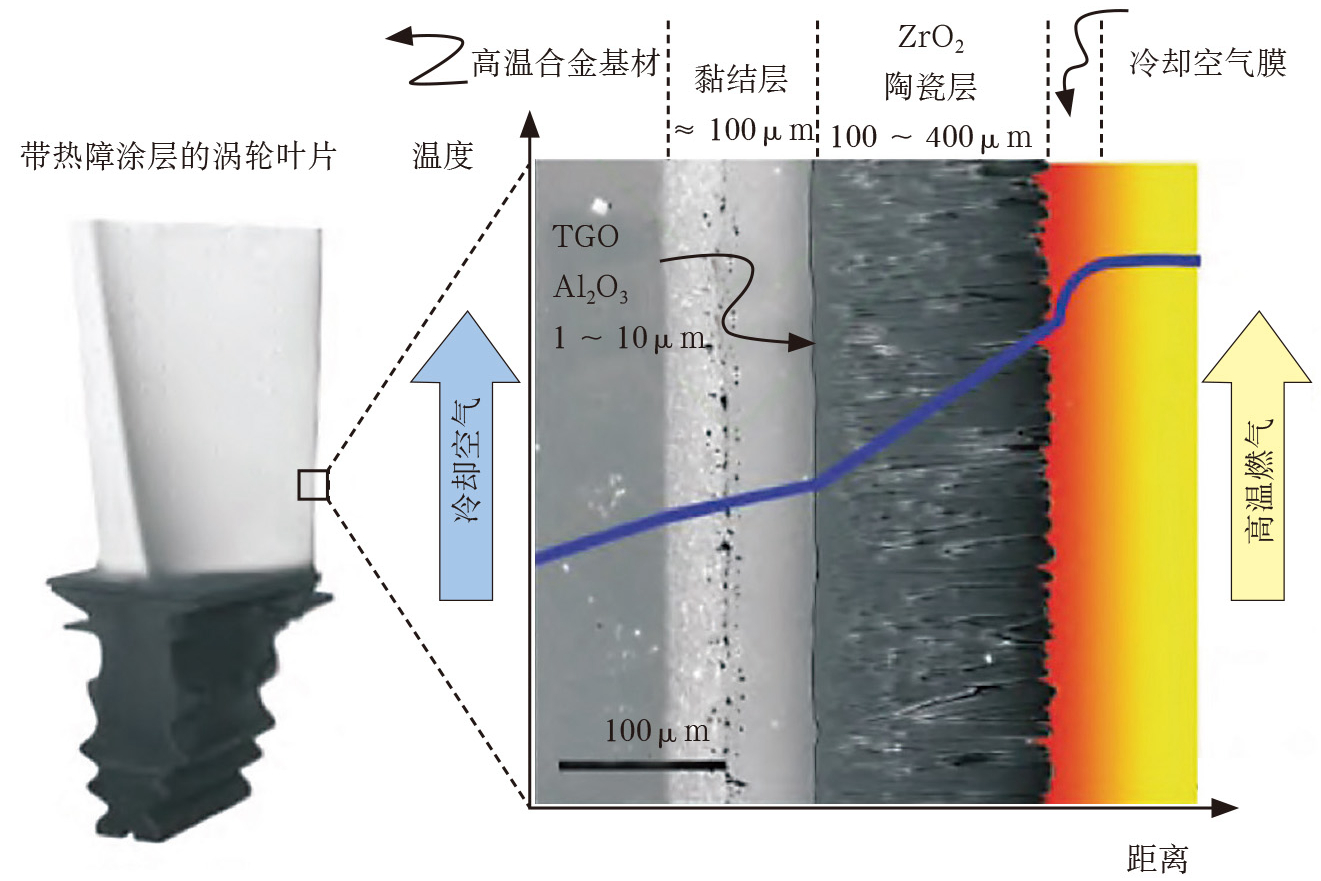

Our Surface Treatment Service offers specialized finishes for custom parts, enhancing durability, aesthetics, and performance. We provide a range of processes, including Electroplating, Anodizing, Powder Coating, and Thermal Barrier Coatings, tailored to improve corrosion resistance, wear properties, and visual appeal of metal and plastic components across industries.

learn more

As Machined

learn more

Painting

learn more

PVD

learn more

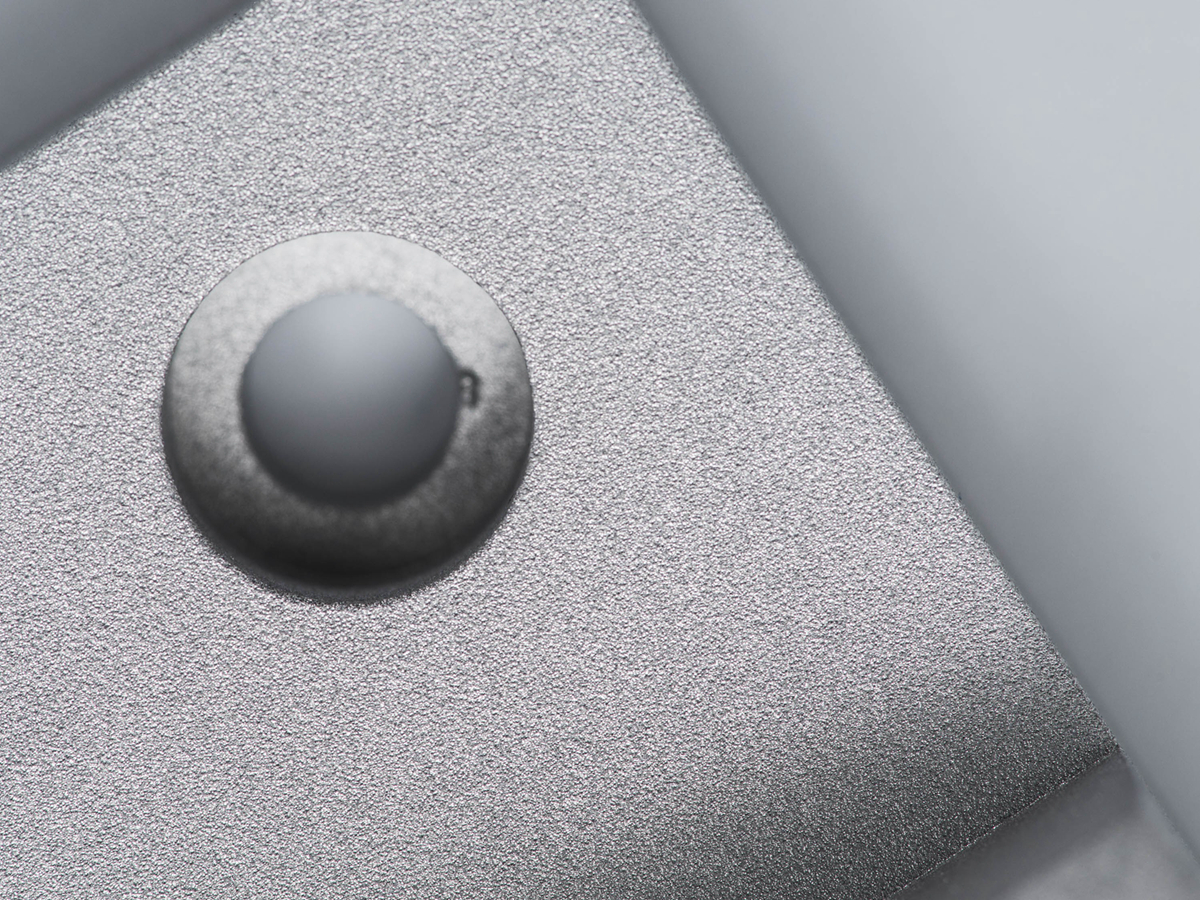

Sandblasting

learn more

Electroplating

learn more

Polishing

learn more

Anodizing

learn more

Powder Coating

learn more

Electropolishing

learn more

IMD

learn more

Brushed Finishes

learn more

Black Oxide

learn more

Heat Treatment

learn more

Tumbling

learn more

Alodine

learn more

Chrome Plating

learn more

Phosphating

learn more

Nitriding

learn more

Galvanizing

learn more

Lacquer Coating

learn more

Teflon Coating

learn more

Thermal Coatings

learn more

Thermal Barrier Coatings

learn more

Passivation

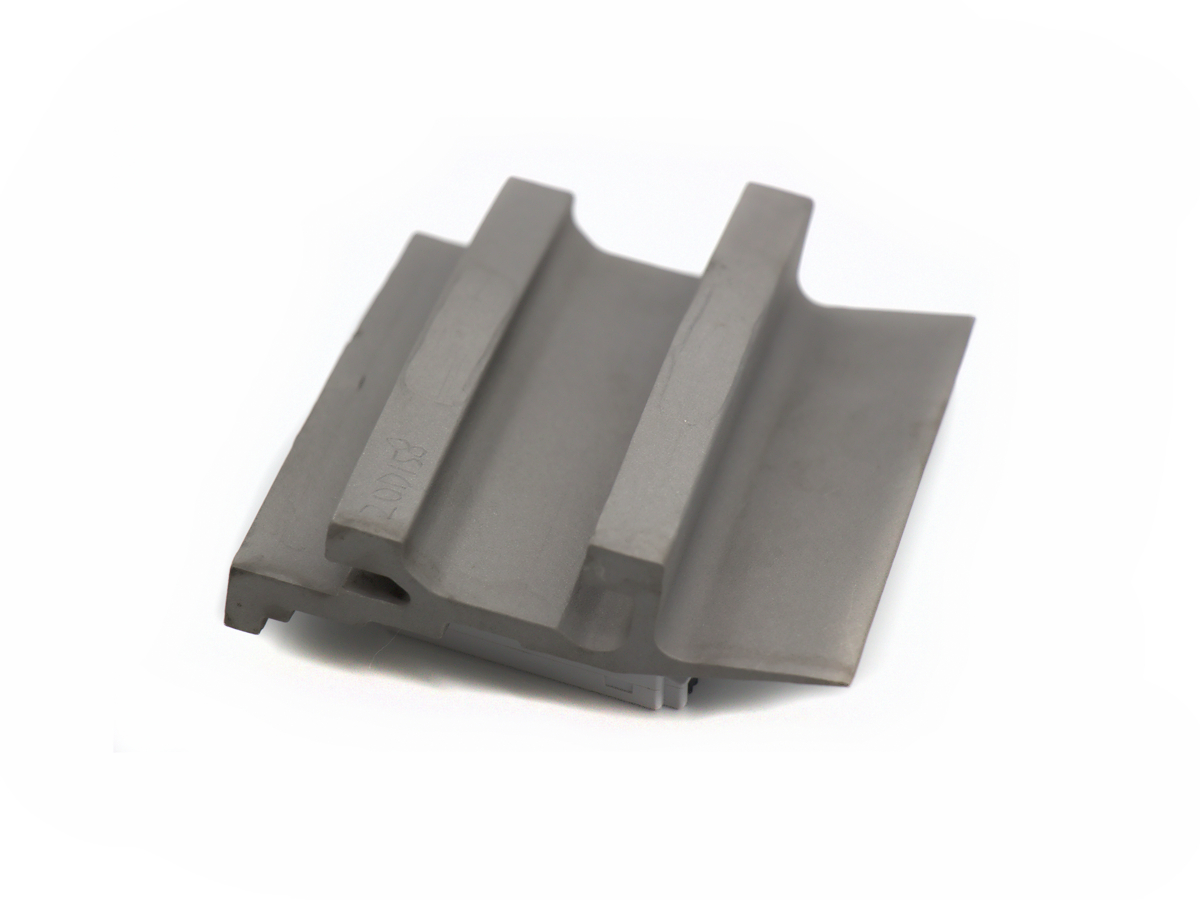

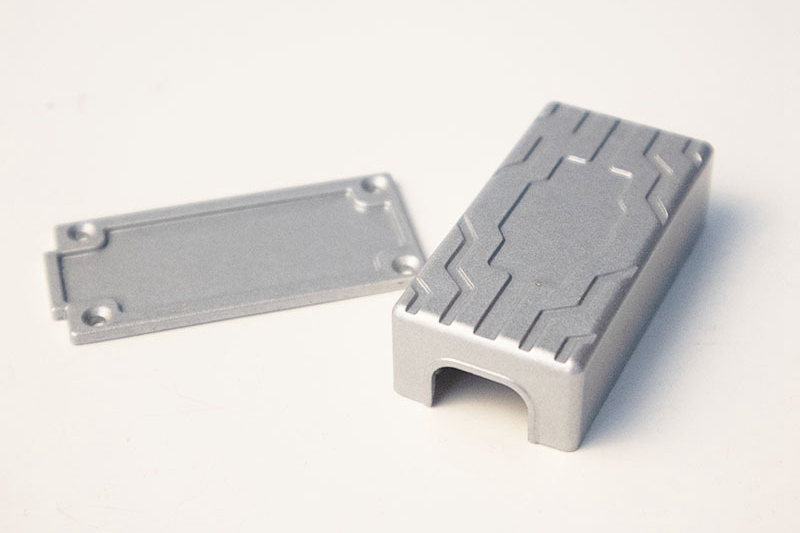

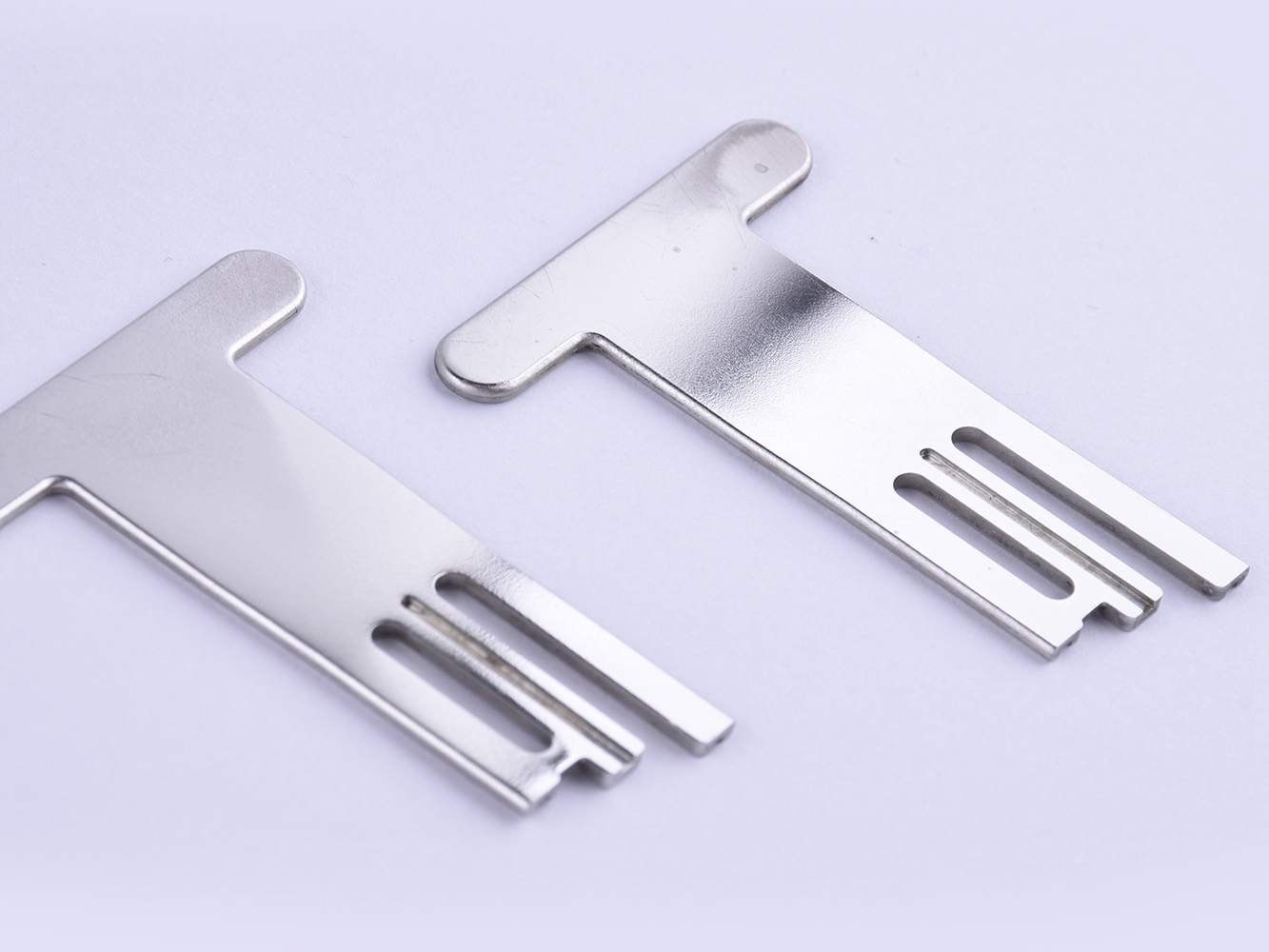

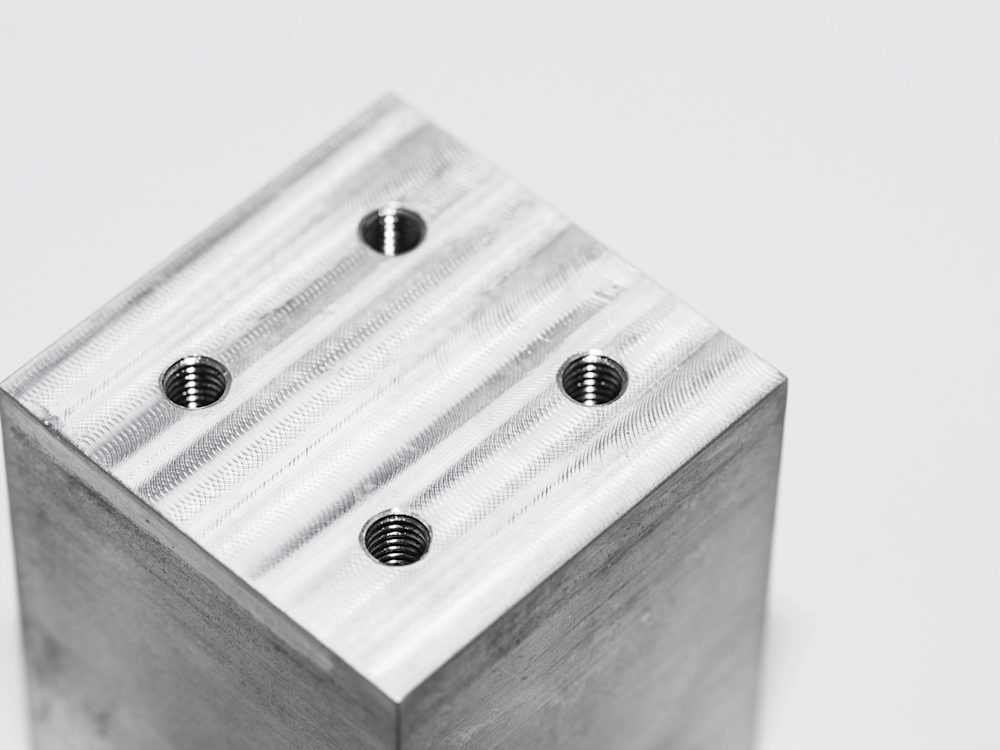

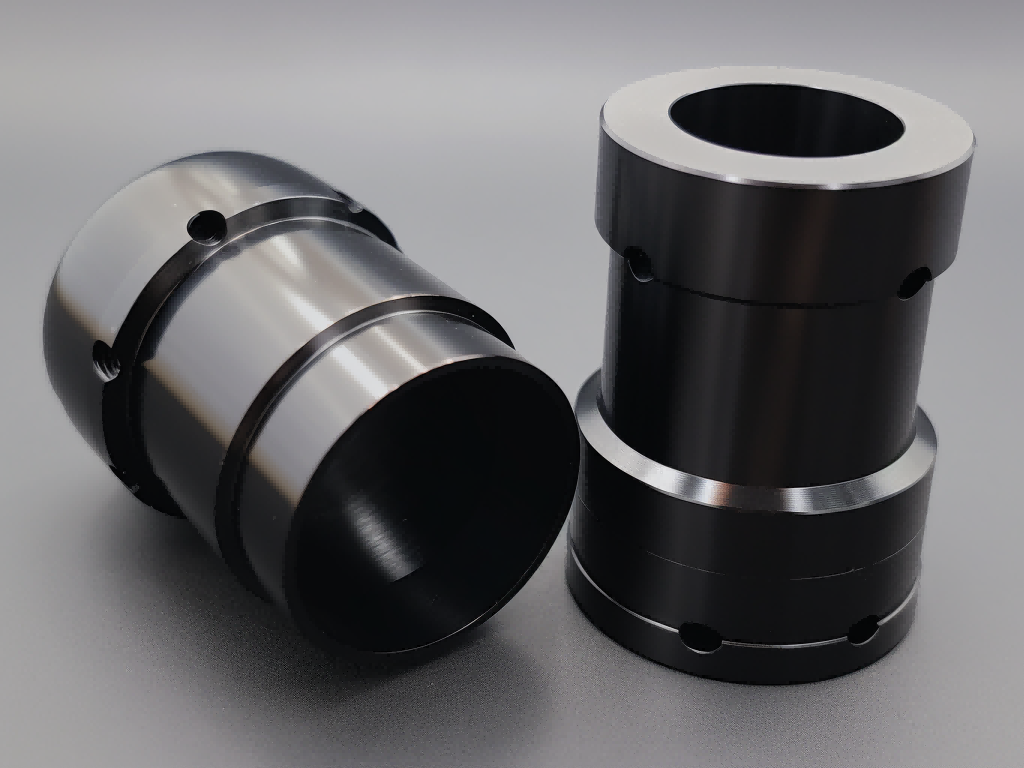

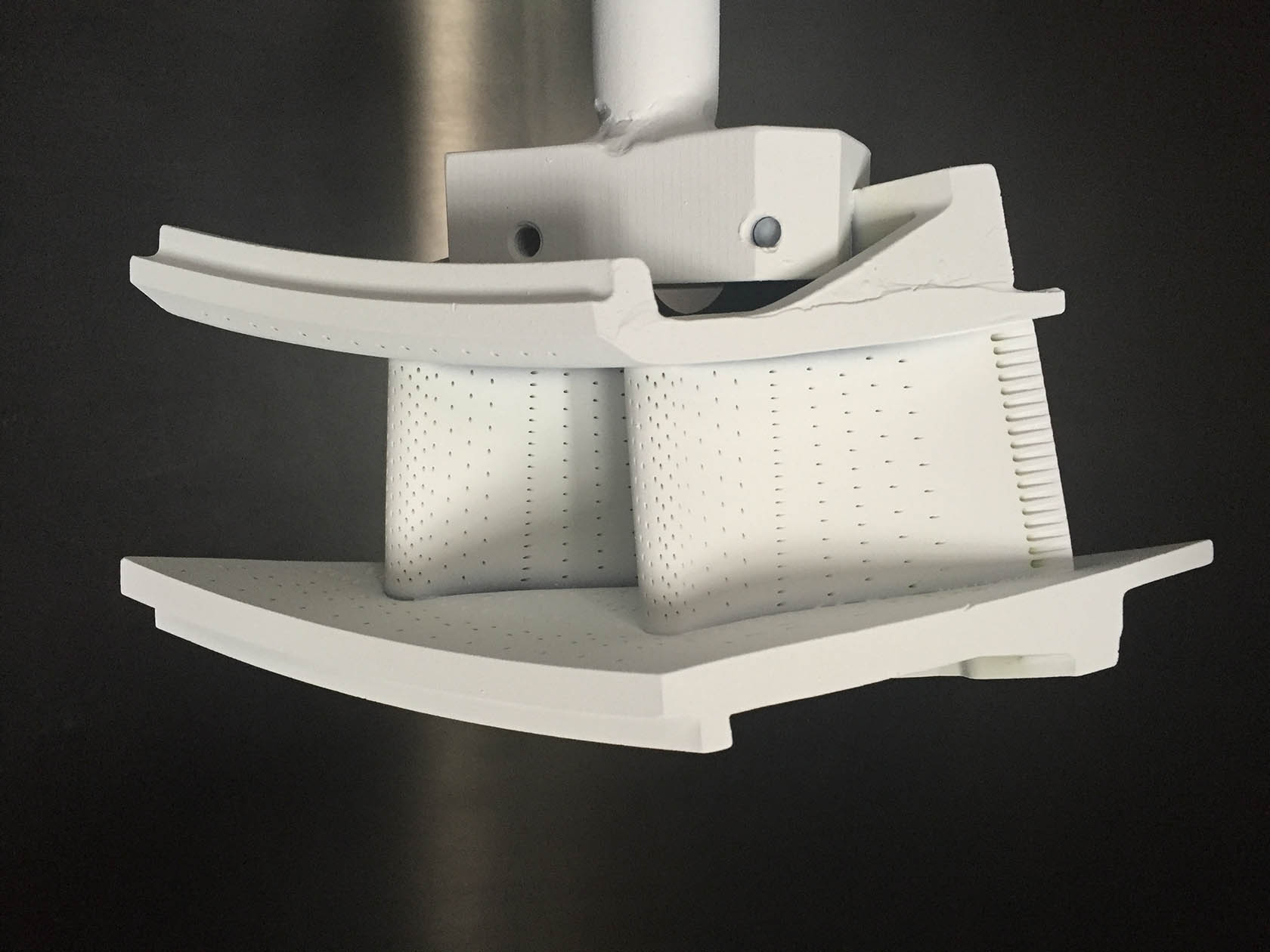

Custom Investment Parts Gallery

Explore our investment cast parts gallery and find out how diverse industries leverage their advantages.

Let's Start A New Project Today

Suggestions for Investment Casting Parts

These guidelines offer strategic design suggestions for investment casting parts to achieve even cooling, reduced defects, and cost-effective production while enhancing part strength and overall quality.

Frequently Asked Questions

Explore Related Resources

Solutions

Copyright © 2025 Neway Precision Works Ltd.All Rights Reserved.