How do we deal with the undercut in injection molding?

In a broad sense, the concept of injection molding is vague because we have different processing methods when dealing with undercuts in plastic injection molding, metal injection molding, and ceramic injection molding. Here are some standard methods to deal with undercuts in injection molding. The choice depends on factors like part geometry, production quantities, mold costs, material properties, and the dimensional accuracy needed.

Part redesign

The first step is to review the part design and identify the areas with undercuts. Modifying the part geometry to eliminate or minimize undercuts is the most effective way to address the issue. Redesigning can involve:

Draft angles.

Changing the parting line.

Splitting the part into multiple pieces allows easy ejection.

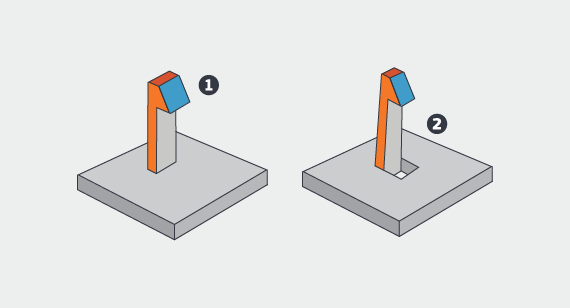

Split Mold Design

The mold is split into two or more separate pieces to release the part with undercuts. The split line will leave a witness mark on the part.

Side Cores

Movable side cores retract to release the undercut features. It adds complexity to the mold but avoids parting lines.

Collapsible Cores

Collapsible Cores are designed to flex or compress for demolding, then spring back into shape afterward, and are used for shallow undercuts.

Unscrewing Parts

Sections of the mold are threaded and unscrewed to release the undercuts. Requires rotational mold opening.

Rotating molds

A rotating mold can be used for parts with complex undercuts. The mold rotates during the ejection process, allowing the part to release smoothly.

Internal Gas Assist

Gas injection into the mold creates hollows to form re-entrant features. Undercuts can be molded as the gas pressure pushes out the core.

Insert Molding

A separate piece with the undercut is molded first, then inserted into the final cavity and over-molded.

Negative Draft Angles

Slight harmful drafts can be pulled if the material is flexible. Not suitable for steep undercuts.

Rapid Prototyping

Methods like 3D printing can make parts with undercuts, as no draft angles are required. Useful for prototypes.

Hand-removal or secondary operations

In some cases, manual labor or secondary operations may be required to remove the part from the mold if other solutions are not feasible. However, this can be time-consuming and unsuitable for high-volume production.

There are also other unique processing methods. For example, we can manufacture the undercut and central part separately for standard plastic injection molding and perform ultrasonic welding.