What factors affect the cost of CNC milling?

CNC milling is a precise and efficient manufacturing process used across various industries. However, the cost of CNC milling can vary significantly based on several factors. Understanding these factors can help in planning and budgeting for your projects. Let’s explore the key elements that influence the cost of CNC milling.

Material Selection

Type of Material: The choice of material plays a crucial role in determining the cost. Common materials include metals like aluminum, steel, and titanium, and plastics like ABS and PEEK. Exotic materials such as titanium or Inconel are more expensive than more common options like aluminum.

Material Hardness: Harder materials, such as hardened steel or ceramics, require slower cutting speeds and more frequent tool changes, leading to higher costs due to increased tool wear and longer machining times.

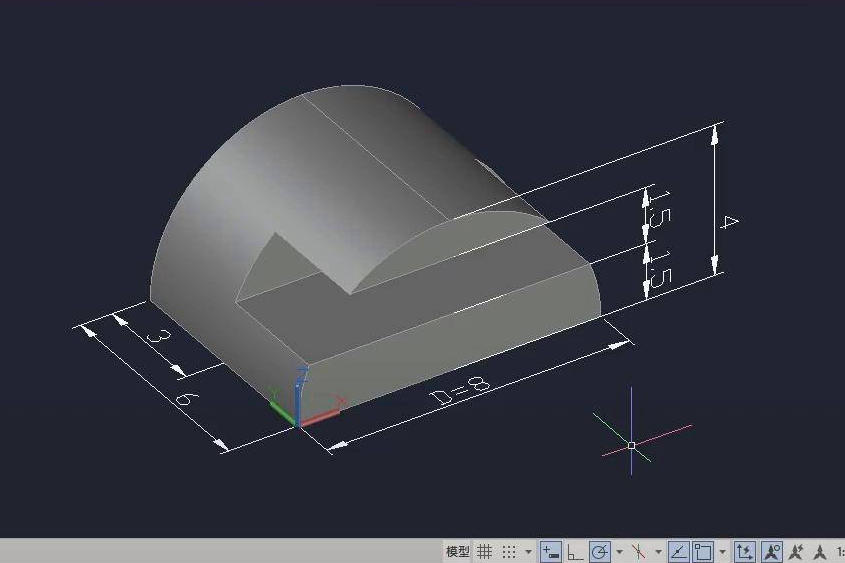

Complexity of the Design

Geometry: Simple shapes like rectangles or cylinders are quicker and cheaper to machine. However, intricate designs with complex shapes, undercuts, and tight tolerances require advanced machinery and more time, increasing the overall cost.

Number of Operations: Parts requiring multiple machining operations, such as turning, drilling, and threading, are more expensive due to the additional time and complexity involved.

Part Size

Dimensions: Larger parts require more material and take longer to machine, which increases costs. Additionally, larger parts may necessitate specialized equipment or multiple setups.

Volume: Bulkier parts might need larger tools and more significant machine power, further impacting the cost.

Tolerance and Surface Finish

Tight Tolerances: High precision (e.g., ±0.001 mm) requires meticulous work and slower machining speeds, which increases costs due to the need for more time and additional quality control measures.

Surface Finish: Higher-quality finishes require additional processes like polishing or coating. For example, achieving a mirror finish can be more expensive than a standard machine finish.

Production Volume

Quantity: Producing a larger volume of parts can reduce the per-unit cost due to economies of scale. Initial setup costs are spread over more parts, making larger batches more cost-effective.

Setup Time: The initial setup involves programming the CNC machine, setting up fixtures, and performing trial runs. This fixed cost is more effectively amortized over a larger production run.

Machine and Tooling Costs

Machine Type: Advanced CNC machines, such as 5-axis machines, are more expensive to operate but can handle more complex parts. They reduce the need for multiple setups, which can save time but increase the cost of machinery.

Tooling: Specialized or custom tooling adds to the cost. Machining hard materials increases tool wear and replacement costs.

Labor Costs

Operator Skill: Skilled operators command higher wages. Complex parts may require more experienced machinists to ensure precision and quality.

Programming: Complex parts require extensive programming time to optimize tool paths, which increases costs.

Lead Time

Urgency: Expedited orders increase costs due to potential overtime work, machine downtime rearrangement, and expedited shipping. Standard lead times allow for more efficient scheduling and lower costs.

Post-Processing Requirements

Secondary Operations: Additional processes like heat treatment, anodizing, or assembly add to the overall cost. These steps may be necessary to meet specific material properties or aesthetic requirements.

Geographic Location

Local Costs: Labor and material costs vary by region. Manufacturing in regions with lower operational costs can reduce overall expenses. Overhead costs such as utilities, rent, and regulatory compliance also vary by location.

Conclusion

Understanding the factors that affect the cost of CNC milling can help in making informed decisions and optimizing production efficiency. By considering material selection, design complexity, part size, tolerance requirements, production volume, machine and tooling costs, labor costs, lead time, post-processing needs, and geographic location, you can better estimate costs and plan your projects effectively.

If you have specific requirements or need assistance with CNC milling, feel free to reach out to us. Our team of experts is ready to help you achieve your manufacturing goals efficiently and cost-effectively.