CNC Prototyping Supplier: 15 Benefits of CNC Rapid Prototyping

CNC machining process brings invaluable benefits to prototyping applications where design flexibility, fast turnaround, high precision, functional testing, frequent iterations, and cost efficiency are critical for accelerating new product development and introductions.

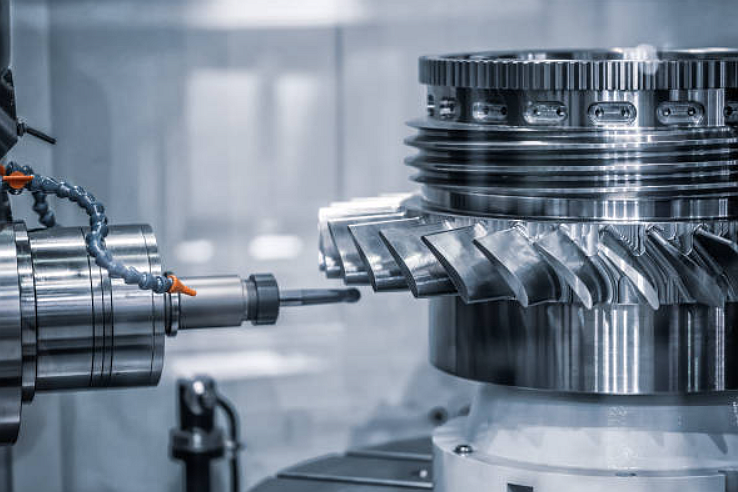

High Precision and Accuracy

One of the most significant benefits of CNC machining is the ability to consistently hold very tight tolerances, often down to +/- 0.005 inches (0.127 mm) or +/- 0.001 inches (0.025 mm) for more precision applications. This high level of accuracy enables the creation of prototypes that closely match the dimensions, geometries, features, and specifications of the final production design intent.

Design and Engineering Validation

The precision of CNC machined prototypes enables comprehensive validation and verification of engineering performance, fit, assembly integration, manufacturability, and intended product functionality under simulated real-world conditions. This "test before production" approach saves enormous time and money.

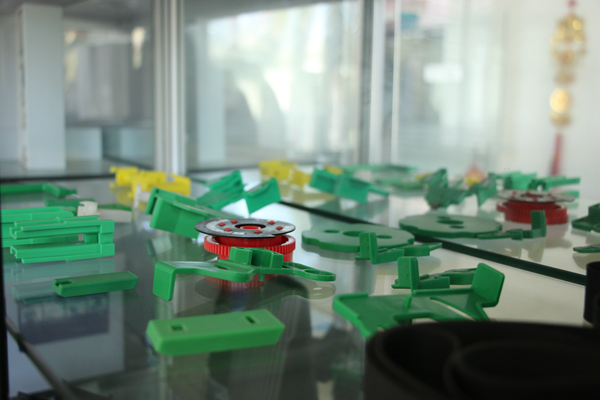

Functional Prototyping

CNC machining utilizes the same production-grade materials as final parts, including metals, plastics, alloys, composites, etc. It allows prototypes to be functional, assembled, and tested under realistic user conditions, fully validating the design. Companies can refine form, fit, and function before committing to production.

Rapid Design Iteration Cycles

A significant CNC machining benefit is turning CAD and CAM files into physical prototypes incredibly fast, often within days or a few weeks versus the months required for complex production tooling. This compressed timeline enables rapid design iterations, improvements, and optimization early in development.

Low Volume Production

While ideal for creating prototypes cost-effectively, CNC machining can also be leveraged for short-run production in tens to hundreds of parts. Low-volume production via CNC machining helps meet market demands while production tooling is still being prepared and approved.

Quick Implementation of Design Changes

With CNC machining, design revisions, enhancements, and improvements can be easily and rapidly incorporated by modifying the CAD models. New prototypes can be quickly fabricated without delays or costs associated with reworking complex tooling. It facilitates design refinement.

Part Consolidation

CNC machining makes consolidating multiple components into single machined parts practical, reducing assemblies. It improves accuracy, minimizes assembly errors, reduces manufacturing steps, and lowers overall costs. Part consolidation is often not feasible with other processes.

Material and Process Validation

CNC machined prototypes allow designers and engineers to simulate, test, and validate different material options, coatings, treatments, and manufacturing processes like injection molding earlier in the design cycle before committing to expensive production tooling.

Parallel Concept Testing

The fast turnaround of CNC machined prototypes means several design concepts can be prototyped and evaluated concurrently. Different design iterations can be analyzed side-by-side to identify the optimal solution based on performance data.

Cost Efficiency

CNC machining eliminates high upfront costs associated with production tooling, like injection molds and stamping dies. Changing designs is accomplished simply by modifying CAD files at a meager incremental cost. The efficiencies multiply for complex geometries and lower production volumes.

Pre-Production Test Parts

After finalizing the design, CNC machining can create pre-production prototypes with near-production fidelity to test out assembly processes, jigs, workflows, and other manufacturing readiness steps before full ramp-up and capital investment in tooling.

Customization Ability

Easily tailor and modify stock designs to create customized end-use products for specialized applications and individual customer needs. Customized dimensions, features, finishes, engravings, materials, and operating specifications are feasible.

Accelerated Time-to-Market

Rapid CNC machined prototypes get products to market faster by enabling on-demand design modifications, real-world testing, early tooling validation, and overlapping development phases that avoid delays.

Essential for New Product Introduction

New product development relies heavily on prototyping solutions for proofs-of-concept, physical models for marketing, regulatory and patent approvals, initiating manufacturing ramp-up, and reducing commercialization risk.

Bridging Prototype to Production

Even after production tooling is completed, CNC machining can still economically fill volume needs during the transition from R&D to total capacity throughput. CNC parts can also serve as masters for mold, jig, and fixture fabrication.

CNC rapid prototyping service has revolutionized the manufacturing landscape, offering many benefits that drive innovation, efficiency, and cost-effectiveness. The advantages are undeniable, from accelerated product development to enhanced customization and reduced waste. As a production engineer at Neway, I've witnessed firsthand the transformative power of CNC rapid prototyping in real-world scenarios.

Neway CNC Prototyping Customer Reviews

"I can't say enough good things about Neway's CNC prototyping service. Their combination of advanced 5-axis CNC precision, knowledgeable engineers, and passion for perfection resulted in the highest quality prototypes for my startup. The fast turnaround times and 20% first order discount made Neway a no-brainer." - Michael