Can CNC milling be used for prototyping?

Introduction

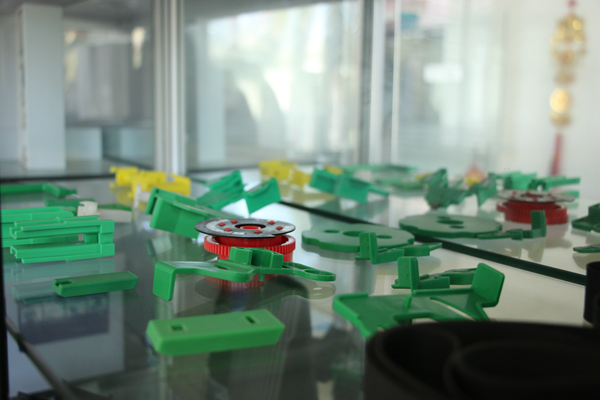

In the fast-paced world of product development, the ability to swiftly iterate designs and produce functional prototypes is paramount. Among the arsenal of manufacturing techniques available, CNC milling stands out as a reliable and versatile method for creating prototypes with precision and efficiency. Let's delve deeper into the capabilities and applications of CNC milling in the realm of rapid prototyping.

Understanding CNC Milling

CNC milling harnesses the power of computer-controlled machines to precisely shape materials according to digital designs. This subtractive manufacturing process involves the use of various cutting tools to remove material from a workpiece, resulting in custom-designed parts with exceptional accuracy and detail.

Advantages of CNC Milling in Prototyping

Precision and Accuracy: CNC milling machines boast impressive accuracy, often achieving tolerances within microns. This level of precision ensures that prototypes closely match the intended design specifications, providing valuable insights during the development process.

Material Versatility: From metals like aluminum and stainless steel to plastics such as ABS and polycarbonate, CNC milling can handle a wide range of materials commonly used in prototyping. This versatility allows engineers and designers to explore different materials and their properties during the prototyping phase.

Complex Geometry: One of the key strengths of CNC milling is its ability to produce complex geometries with ease. Whether it's intricate patterns, organic shapes, or multi-axis machining, CNC milling machines excel at tackling challenging designs that may be impractical or impossible with other manufacturing methods.

Speed and Efficiency: With advancements in machine technology and programming software, CNC milling has become increasingly efficient, reducing lead times for prototyping projects. Rapid tool changes, high spindle speeds, and optimized machining strategies contribute to faster turnaround times, allowing teams to iterate designs quickly and accelerate time-to-market.

Cost-Effectiveness: While the initial setup costs for CNC milling may be higher compared to some other rapid prototyping methods, such as 3D printing, the cost per part tends to decrease for larger production runs. Additionally, the ability to work with a wide range of materials and achieve tight tolerances can result in cost savings over the lifecycle of a product.

Real-World Applications

The versatility and precision of CNC milling have made it indispensable across a wide range of industries:

Automotive Prototyping: In the automotive industry, CNC milling is used to create prototypes of engine components, vehicle interiors, and exterior body panels. These prototypes undergo rigorous testing and validation to ensure compliance with safety and performance standards.

Medical Device Development: CNC milling plays a crucial role in the development of medical devices, ranging from surgical instruments to implantable devices. The ability to produce prototypes with biocompatible materials and intricate geometries is essential for testing functionality and ergonomics.

Aerospace Innovation: From lightweight structural components to complex aerospace assemblies, CNC milling is instrumental in prototyping advanced aerospace technologies. The ability to machine high-strength materials like titanium and composites ensures that prototypes meet the stringent requirements of the aerospace industry.

Consumer Electronics: In the fast-paced world of consumer electronics, rapid prototyping is essential for staying ahead of the competition. CNC milling enables the quick iteration of smartphone casings, wearable device housings, and electronic enclosures, allowing companies to test designs and incorporate user feedback rapidly.

Conclusion

In conclusion, CNC milling offers a powerful solution for rapid prototyping, combining precision, versatility, and efficiency in one package. While it may not be suitable for every prototyping need, its capabilities make it a valuable tool for engineers and designers seeking to bring their ideas to life. As technology continues to evolve, CNC milling is poised to remain at the forefront of rapid prototyping, driving innovation across industries and shaping the future of product development.