360

Casting Properties And Applications of Aluminum 360

Aluminum 360, also known as A360, is a high-silicon-content alloy predominantly used in casting applications due to its excellent castability and mechanical properties. Its key characteristics make it a preferred choice for various industries, particularly in precision casting methods like die casting, sand casting, and gravity casting.

Precision Casting:

Aluminum 360 in Die Casting: It's a favored material for die casting due to its high fluidity, which enables intricate designs and complex shapes. Its excellent machinability allows tight tolerances and smooth surface finishes, making it ideal for high-precision parts, such as electronics or automotive components housings.

Sand Casting:

Aluminum 360's Suitability: In sand casting, its fluidity allows it to fill the fine details of molds, resulting in precise and detailed casts. This alloy's properties make it an excellent choice for manufacturing parts with complex geometries and a high degree of intricacy, such as engine components or decorative elements in architectural applications.

Gravity Casting:

Benefits in Gravity Casting: Aluminum 360 performs well due to its high strength, corrosion resistance, and thermal conductivity. It's often used for parts where strength and durability are essential, like aerospace components or structural parts in machinery and equipment.

Applications Across Industries: Aluminum 360 finds applications across diverse industries, from automotive and aerospace to consumer electronics and industrial equipment. Its versatility and properties make it attractive for manufacturers seeking lightweight yet robust components.

Properties of Cast Aluminum 360

Chemical Composition of Aluminum 360

Silicon (Si) | Iron (Fe) | Copper (Cu) | Magnesium (Mg) | Manganese (Mn) | Nickel (Ni) | Zinc (Zn) | Titanium (Ti) | Other Elements |

|---|---|---|---|---|---|---|---|---|

9.00 - 10.00 | 0.60 - 1.20 | 0.50 - 1.20 | 0.35 max | 0.35 max | 0.25 max | 0.25 max | 0.15 max | Each 0.05 max, Total 0.15 max |

Function of Chemical Components

Each chemical component in Aluminum 360 serves a specific function that contributes to its properties and performance:

Silicon (Si):

Enhances the fluidity of the molten metal, aiding in the casting process. It also contributes to improving strength and wear resistance.

Iron (Fe):

Provides strength and hardness to the alloy, improving its mechanical properties.

Copper (Cu):

It enhances corrosion resistance and improves the alloy's ability to withstand wear. It also contributes to improving machinability.

Magnesium (Mg):

Acts as a grain refiner, enhancing the mechanical properties and promoting a better surface finish. It also contributes to improving corrosion resistance.

Manganese (Mn):

It helps control structure, enhance strength, and improve castability.

Nickel (Ni):

Enhances strength and toughness, particularly at low temperatures.

Zinc (Zn):

Provides added strength to the alloy.

Titanium (Ti):

Acts as a grain refiner, contributing to improved mechanical properties and castability.

Other Elements: Including trace elements, they refine the microstructure, minimize impurities, and ensure consistent properties across the castings.

This precise combination and proportion of elements in Aluminum 360 make it an excellent choice for various casting processes. It offers high strength, corrosion resistance, machinability, and the ability to achieve intricate designs and shapes. Each component shapes the alloy's properties, making it suitable for various industry applications.

Physical and Mechanical Properties

Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (Brinell) | Shear Strength (MPa) | Impact Strength (J) | Fatigue Strength (MPa) | Thermal Conductivity (W/m·K) | Density (g/cm³) | Melting Range (°C) |

|---|---|---|---|---|---|---|---|---|

230 | 170 | 65 | 150 | 6 | 70 | 120 | 2.68 | 582 - 652 |

Typical Applications of Aluminum 360 Castings

Aluminum 360 Casting Automotive Components

Aluminum 360 casting primarily provides significant automotive component advantages due to its lightweight yet robust nature. The low density of Aluminum 360 contributes to creating automotive parts that are notably lighter than their counterparts made from other materials. This characteristic is instrumental in enhancing fuel efficiency and overall vehicle performance, aligning with the automotive industry's continuous pursuit of more sustainable and eco-friendly solutions.

The high strength-to-weight ratio of Aluminum 360 is another standout feature. Despite its lightweight composition, it exhibits excellent strength, ensuring that automotive components maintain durability and structural integrity. This attribute is crucial in applications where strength and reduced weight are paramount, improving vehicle efficiency and performance.

Furthermore, Aluminum 360's corrosion resistance is crucial for automotive components exposed to diverse environmental conditions. The material's ability to withstand corrosion contributes to the longevity and reliability of critical parts, enhancing vehicles' overall durability and maintenance requirements. Combined with its excellent machinability, cost-effectiveness, and recyclability, Aluminum 360 emerges as a versatile and sustainable choice for shaping the future of automotive engineering.

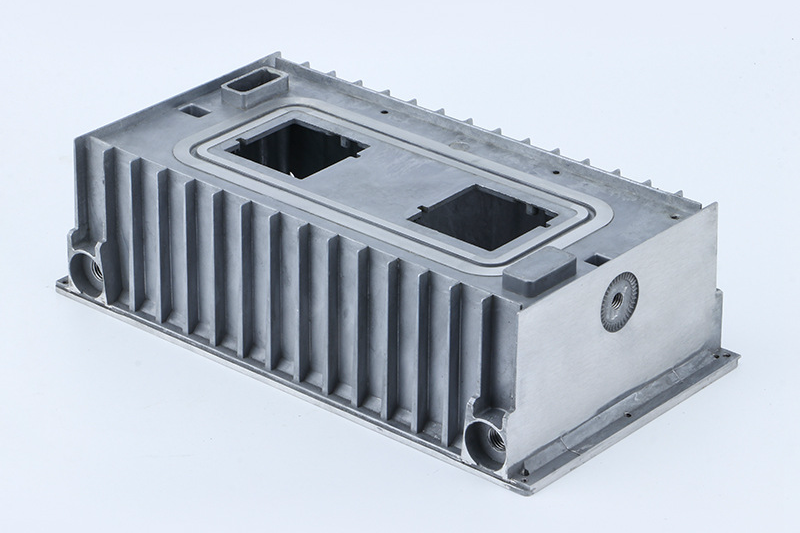

Aluminum 360 Casting Enclosures for Electronic Devices

Aluminum 360 casting offers compelling benefits for enclosures used in electronic devices, making it a preferred material for this application. One key advantage is the material's excellent thermal conductivity. Aluminum efficiently dissipates heat generated by electronic components, preventing overheating and ensuring optimal device performance. This property is particularly crucial for enclosures housing sensitive electronic circuits that can be affected by high temperatures.

The lightweight nature of Aluminum 360 is another significant benefit. Electronic devices are becoming increasingly compact and portable, and using lightweight materials is essential for achieving sleek designs without compromising structural integrity. Aluminum 360's low density allows for creating durable and lightweight enclosures, meeting the demands of modern consumer electronics.

Additionally, Aluminum 360 provides inherent corrosion resistance, safeguarding electronic devices from environmental factors such as moisture and humidity. This property contributes to the longevity and reliability of electronic enclosures, ensuring that sensitive internal components remain protected over time. The versatility of Aluminum 360 casting allows for the production of intricately designed enclosures, meeting the evolving needs of the electronics industry for both functionality and aesthetics. Overall, Aluminum 360 stands out as a material that combines thermal efficiency, lightweight construction, and corrosion resistance, making it an ideal choice for enclosures in electronic devices.

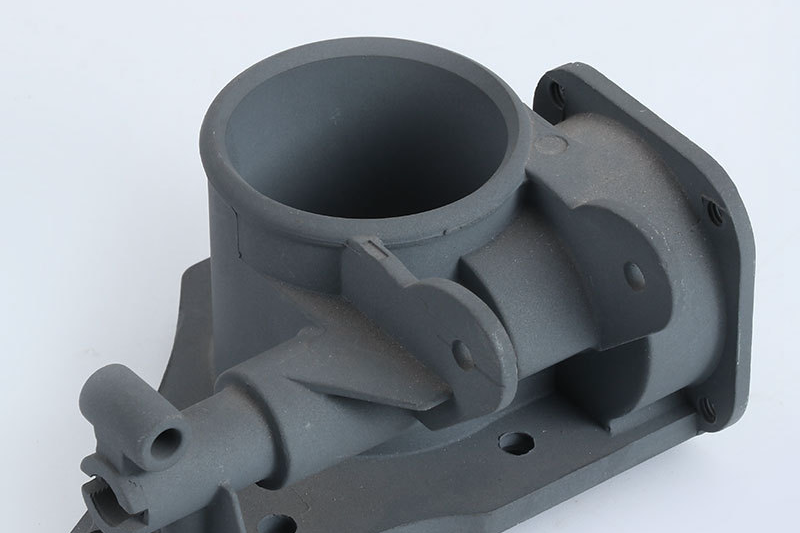

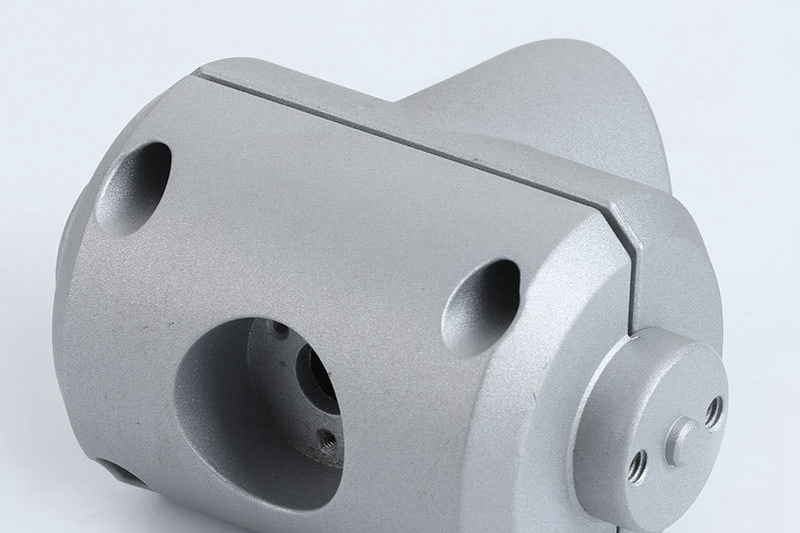

Aluminum 360 Casting Pump Housings

Aluminum 360 casting offers several key benefits when used for pump housings, making it a material of choice for various applications in the pumping industry. One primary advantage is the material's excellent corrosion resistance. Pump housings often come into contact with liquids and are exposed to varying environmental conditions. The natural corrosion resistance of Aluminum 360 ensures the durability of pump housings, reducing the risk of degradation over time and enhancing the reliability of pumping systems.

The lightweight nature of Aluminum 360 is particularly beneficial for pump housings. Pumps are integral components in many industries, and using lightweight materials helps optimize energy efficiency and ease of installation. Aluminum 360's low density allows for the production of pump housings that are not only robust but also contribute to overall system efficiency by minimizing weight and energy requirements.

Furthermore, Aluminum 360 casting facilitates the creation of intricate and complex designs, which is advantageous for pump housing applications. The casting process allows for producing pump housings with precise shapes and features, meeting the specific requirements of different pump systems. This versatility in design contributes to the adaptability of Aluminum 360 for a wide range of pumping applications across industries.

Aluminum 360 Casting Bicycle Components

The utilization of Aluminum 360 casting in the production of bicycle components offers numerous advantages, making it a favored material for various parts in the cycling industry. One primary benefit is its lightweight composition. Aluminum 360's low density enables the creation of bicycle components that are both durable and exceptionally light, contributing to overall weight reduction in bicycles. It is crucial for cyclists, as lighter components enhance maneuverability, speed, and overall riding efficiency.

Another notable advantage is the material's excellent strength-to-weight ratio. Despite its lightweight nature, Aluminum 360 provides robustness and structural integrity to bicycle components. It ensures that critical parts, such as frames, handlebars, and wheel components, maintain durability and performance under the stresses encountered during cycling activities.

Additionally, Aluminum 360's corrosion resistance is vital for bicycle components exposed to outdoor conditions. Bikes are often used in various weather environments, and the material's ability to resist corrosion helps prolong the lifespan of components, reducing the need for frequent maintenance. This durability and the ease of casting intricate designs allow for creating high-performance and aesthetically pleasing bicycle components.

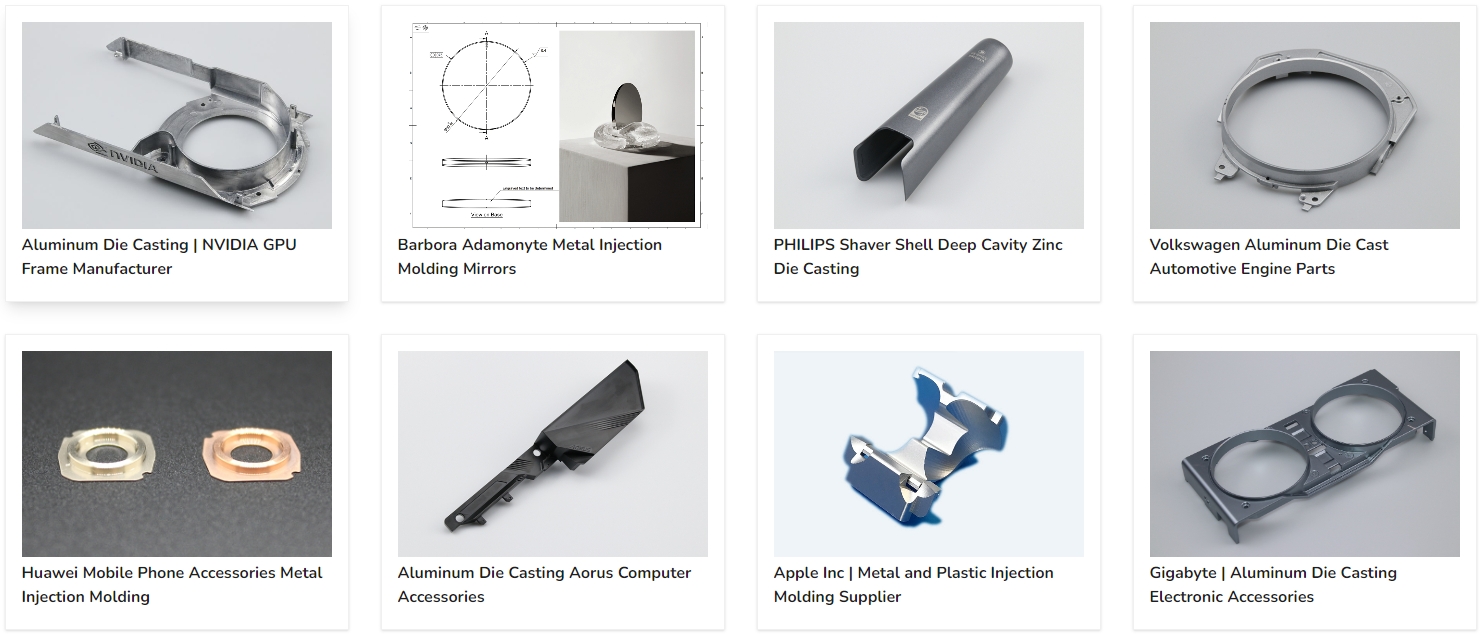

Brand Case Study

Neway has served many world-renowned companies, using its strong manufacturing capabilities and complete quality control system to provide further market competitiveness and quality assurance for major brands.