Nickel 200

Basic description of Nickel 200 Powder

Nickel 200 powder is a commercially pure (99.6%) nickel alloy recognized for its excellent mechanical properties and corrosion resistance. It offers high thermal and electrical conductivity, making it a versatile choice for various industrial applications. The powder form of Nickel 200 is finely processed to ensure high purity and consistency, optimizing it for advanced manufacturing processes such as additive manufacturing (3D printing), where these characteristics are crucial for achieving high-quality parts with uniform properties.

Nickel 200 Similar grades

Nickel 200, also called UNS N02200, W.Nr.2.4060, Ni200 shares properties with other nickel alloys, providing a range of options for specific applications:

Nickel 201: Similar to Nickel 200 but with a lower carbon content, it is more suitable for applications where the alloy might be exposed to temperatures above 600°F (315°C), reducing the risk of graphitization.

Monel 400: A nickel-copper alloy known for its excellent corrosion resistance, particularly in marine and acidic environments. While not as pure as Nickel 200, it offers added strength and hardness.

Inconel 600: A nickel-chromium alloy with high strength and resistance to high temperatures and corrosive environments. It is more suited for applications requiring higher strength and oxidation resistance at elevated temperatures.

Hastelloy C-276: A nickel-molybdenum-chromium alloy noted for its outstanding corrosion resistance in severe environments. This alloy is often chosen for chemical processing applications.

Applications

Nickel 200 powder, with its high purity and excellent mechanical properties, finds extensive use across a broad spectrum of industrial applications. Its inherent corrosion resistance, coupled with high thermal and electrical conductivity, makes it particularly suitable for environments where these attributes are critical. Here's a detailed look at specific applications of Nickel 200:

1. Chemical Processing Equipment: Nickel 200 is extensively used in the manufacturing of reactors, vessels, pipes, and heat exchangers in the chemical processing industry. Its corrosion resistance to various chemicals, including caustic solutions, makes it ideal for handling and processing corrosive substances.

2. Food Processing: Due to its corrosion resistance and being free from contamination risks, Nickel 200 is used in food processing equipment, storage tanks, and utensils. Its non-reactive nature ensures no alteration in the taste or properties of food products.

3. Electrical and Electronic Components: Leveraging its excellent electrical conductivity, Nickel 200 powder is utilized to produce electrical resistance wires, battery connections, and lead wires for heating elements. It ensures reliable performance in electrical applications.

4. Aerospace and Aviation: Nickel 200's resistance to high-temperature corrosion makes it suitable for aerospace components, including gas turbine engines and exhaust systems, where high thermal stability is required.

5. Energy Production: In power generation, especially in renewable energy systems like solar and wind power, Nickel 200 makes battery electrodes and conductors due to its high electrical conductivity and corrosion resistance.

6. Marine Engineering: Its excellent resistance to seawater corrosion makes Nickel 200 a preferred choice for marine applications, including shipbuilding and repair, where materials are constantly exposed to aggressive marine environments.

7. Synthetic Fiber Production: Nickel 200 is used in the components of machines that produce synthetic fibers. Its corrosion resistance is crucial in processes involving corrosive chemicals.

Nickel 200 Composition and Properties

Nickel 200 is distinguished by its high purity and outstanding mechanical and chemical properties, making it suitable for various industrial applications. Its composition and properties are tailored to offer superior performance, particularly in environments requiring corrosion resistance and high thermal and electrical conductivity.

Composition:

The chemical composition of Nickel 200 is as follows:

Nickel (Ni): Approximately 99.6%, providing the base for its excellent corrosion resistance and thermal and electrical conductivity.

Carbon (C): 0.15% max, minimizes carbide precipitation and enhances corrosion resistance.

Manganese (Mn): 0.35% max improves the alloy's strength and resistance to corrosion.

Silicon (Si): 0.35% max enhances strength and forms a protective oxide layer on the surface.

Sulfur (S): 0.01% max, controlled to minimize adverse effects on corrosion resistance.

Iron (Fe): 0.40% max, present as a minor component to enhance mechanical properties without significantly affecting the corrosion resistance.

Copper (Cu): 0.25% max, adding strength and corrosion resistance to the alloy.

Properties:

Leveraging this composition, Nickel 200 exhibits a range of properties ideal for challenging applications:

Excellent Corrosion Resistance: It is ideal for chemical processing applications involving caustic solutions in reducing environments.

High Thermal Conductivity: Enables efficient heat transfer and is suitable for heat exchangers and electrical applications requiring rapid heat dissipation.

Superior Electrical Conductivity: This makes it ideal for electrical and electronic components, offering reliable performance.

Good Mechanical Properties: Maintains a balance of strength and flexibility at room temperature and retains strength at elevated temperatures.

Magnetostrictive Properties: Useful in special applications requiring converting magnetic energy into kinetic energy, such as actuators and sensors.

Weldability: Can be easily welded, soldered, and brazed, offering flexibility in manufacturing complex assemblies.

Applications Stemming from Composition and Properties:

Given its corrosion resistance and thermal and electrical conductivity, Nickel 200 is extensively used in chemical processing equipment, food processing, electrical and electronic components, and other applications requiring a material that maintains integrity in corrosive environments and under thermal stress. Its unique blend of properties ensures that components made from Nickel 200 can withstand the rigors of severe industrial conditions, enhancing efficiency and safety across a wide range of applications.

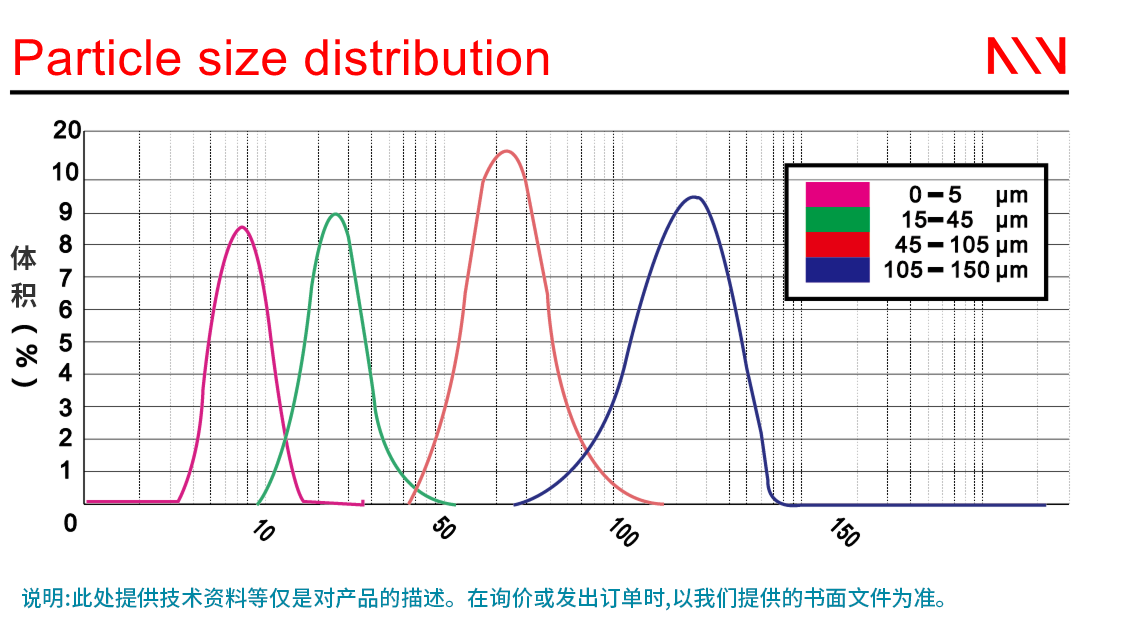

Powder Characteristics

The performance of Nickel 200 in advanced manufacturing processes, especially those involving powder metallurgy techniques such as additive manufacturing (3D printing), metal injection molding (MIM), and powder compression molding (PCM), is significantly influenced by the specific characteristics of its powder form. These characteristics ensure the manufacturing process yields components with the desired mechanical properties and high-quality surface finishes.

Yield Strength:

Yield strength indicates the stress at which a material begins to deform plastically. Nickel 200 parts typically exhibit a yield strength of 15,000 to 25,000 psi. It indicates the material's capability to withstand significant stress before experiencing permanent deformation, making it suitable for various applications, including those involving chemical processing and electrical components.

Tensile Strength:

Tensile strength represents the maximum stress a material can withstand while being stretched or pulled before breaking. Parts made from Nickel 200 powder can achieve tensile strengths of approximately 55,000 to 75,000 psi, indicative of high durability and performance under tensile loads. This strength is essential for components that must maintain structural integrity under operational stresses.

Elongation:

Elongation measures the flexibility of a material or how much it can stretch before it breaks. Manufactured parts from Nickel 200 typically show an elongation range of 35% to 55%, demonstrating good ductility. This characteristic allows components to absorb significant energy or withstand impacts, making them suitable for various industrial applications.

Nickel 200 Physical Properties

The physical properties of Nickel 200 powder play a crucial role in its applicability across various manufacturing processes and directly impact the performance of the final manufactured components. Understanding these properties is essential for optimizing production techniques and ensuring the desired quality of the finished parts.

Density:

Nickel 200 has a density of approximately 8.9 g/cm³, indicating its compact atomic structure. This high density is essential for manufacturing parts with minimal porosity, enhancing their strength and durability, especially in environments where corrosion resistance and thermal conductivity are critical.

Hardness:

Manufactured components from Nickel 200 powder exhibit significant hardness, contributing to their wear resistance and mechanical durability. This property is fundamental in applications where components are subject to abrasive or erosive conditions, ensuring longevity and reliability.

Specific Surface Area:

The specific surface area of Nickel 200 powder influences its reactivity and sinterability. A higher specific surface area allows for more effective sintering, leading to more substantial, denser parts. This characteristic is crucial for additive manufacturing and metal injection molding processes, where part integrity depends on the powder's sintering behavior.

Sphericity:

The sphericity of the powder particles affects their flowability and packing density, which are essential factors for achieving uniformity and consistency in manufactured parts. High sphericity ensures smooth flow through the equipment and uniform layering or packing, which is critical for manufacturing accuracy and repeatability in 3D printing and MIM processes.

Bulk Density:

Nickel 200 powder's bulk density impacts the efficiency of powder handling and the quality of the final part. An optimized bulk density promotes easy handling and efficient compaction, essential for achieving uniform part density and optimal mechanical properties.

Hall Flow Rate:

This property measures the powder's ability to flow through an orifice, affecting the precision and repeatability of powder-based manufacturing processes. An excellent Hall Flow Rate indicates good flowability, enabling accurate and consistent part fabrication, especially in additive manufacturing.

Melting Point:

Nickel 200 has a melting point suitable for its specific manufacturing processes, typically around 1455°C (2651°F). This property ensures the material's stability and performance during high-temperature applications, which is crucial for 3D printing and casting processes.

Relative Density:

After processing, the relative density of parts can reach near theoretical density, which is crucial for achieving optimal mechanical strength and minimizing porosity, thereby enhancing component performance in demanding environments.

Recommended Layer Thickness:

For additive manufacturing processes, the optimal layer thickness of Nickel 200 powder ensures fine detail without compromising structural integrity, efficiently balancing resolution with build time.

Thermal Expansion Coefficient:

The alloy exhibits a thermal expansion coefficient that ensures compatibility with other materials in composite structures, maintaining dimensional stability across a wide temperature range.

Thermal Conductivity:

Its thermal conductivity allows for efficient heat dissipation, vital for components that experience high thermal loads during operation.

Technical Standard:

Nickel 200 powder and parts manufactured from it adhere to rigorous technical standards, ensuring reliability, quality, and compatibility with international manufacturing requirements.

Manufacturing Techniques

Nickel 200, known for its excellent corrosion resistance and high thermal and electrical conductivity, is suitable for various advanced manufacturing processes. The selection of the most appropriate manufacturing technique depends on the application requirements and the desired properties of the final part. This section explores compatible manufacturing processes for Nickel 200, compares outcomes across different methods, and discusses common issues and solutions.

1. Which manufacturing processes are Nickel 200 suitable for?

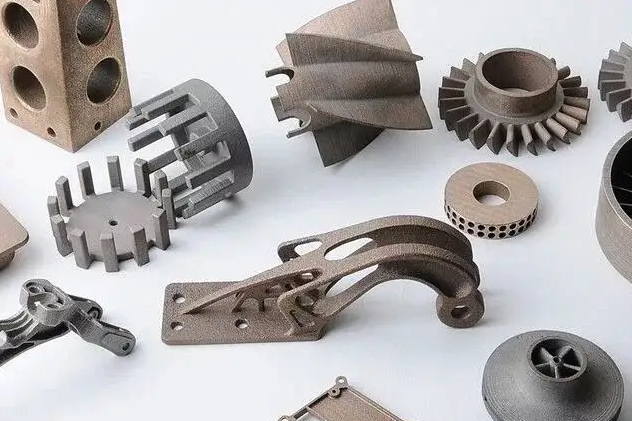

3D Printing (Additive Manufacturing): Nickel 200 is ideal for powder bed fusion techniques such as laser sintering, where its corrosion resistance and conductive properties can be fully utilized in creating complex components for chemical processing and electrical applications.

Metal Injection Molding (MIM): This method is effective for high-volume production of small to medium-sized parts with complex shapes. It leverages Nickel 200's properties for producing dense, precise components with excellent finish, suitable for electrical connectors and corrosion-resistant parts.

Powder Compression Molding (PCM): Suitable for more significant components, PCM can utilize Nickel 200 powder to produce parts with uniform material properties. This process is beneficial for creating structural components in chemical processing equipment.

Vacuum Casting: While less common for metals like Nickel 200, vacuum casting can be used for prototyping and small-batch production, especially when precise control over material properties is less critically required.

Hot Isostatic Pressing (HIP): HIP enhances the properties of parts made from Nickel 200 powder, especially those manufactured through additive manufacturing or PCM, by reducing porosity and improving material density.

CNC Machining: Nickel 200 can be machined into final or semi-final parts. CNC machining is often used to achieve precise dimensions and delicate features on components initially formed by other methods.

2. Comparison of parts produced by these manufacturing processes:

Surface Roughness: Additive manufacturing processes may produce parts with higher surface roughness than MIM or CNC machining, necessitating post-processing to achieve the desired finish.

Tolerances: CNC machining and MIM typically offer tighter tolerances than additive manufacturing or PCM, which might require additional finishing to meet specific requirements.

Internal Defects: Additive manufacturing and PCM can introduce internal porosity or defects not present in parts produced through MIM or CNC machining. HIP can mitigate these issues.

Mechanical Properties: While additive manufacturing can produce parts with comparable mechanical properties to traditional methods, specific treatments such as HIP might be necessary to optimize the performance of Nickel 200 components.

Compactness: MIM and CNC machining generally yield higher-density parts and fewer defects, which is crucial for applications requiring optimal material properties.

3. Normal issues and solutions in these manufacturing processes:

Surface Treatment: Techniques such as mechanical polishing, electro-polishing, or chemical etching are often required to improve surface finish, especially for additive manufactured parts.

Heat Treatment: Specific heat treatments can enhance the corrosion resistance and mechanical properties of Nickel 200 parts, tailored to the final application requirements.

Tolerance Achievement: Precision machining or grinding may be necessary to achieve tight tolerances on additive manufacturing or PCM parts.

Deformation Problems: Components susceptible to deformation during processing can be countered with careful design, support strategies in additive manufacturing, or subsequent straightening processes.

Cracking Problems: Minimizing residual stresses through proper heat treatment and employing gradual cooling rates can help prevent cracking in Nickel 200 components.

Detection Methods: Non-destructive testing methods such as X-ray tomography or ultrasonic testing are crucial for identifying internal defects or porosity within Nickel 200 parts.

Manufacturing With Hastelloy B-2

Main manufacturing processes:

Nickel-based high-temperature alloys are usually used for corrosion resistance, high-temperature resistance, and other extreme working conditions, such as impellers, pump valves, auto parts, etc. Neway has a variety of processing techniques for manufacturing nickel-based high-temperature alloy parts and solving their problems, such as deformation, cracking, and porosity.

Powder compression molding (PCM)

Get A FREE PROTOTYPING SERVICE NOW!: Consultative Design Service at Neway