HastelloyB-2

Basic Description of Hastelloy B-2 Powder

Hastelloy B-2 powder is a nickel-based alloy known for its excellent corrosion resistance, particularly in reducing environments such as those containing hydrochloric and sulfuric acids. This alloy is designed for use in various advanced manufacturing processes, including additive manufacturing (3D printing), where its powder form enables the creation of complex components with high precision. Hastelloy B-2's resistance to stress-corrosion cracking and pitting makes it ideal for harsh chemical processing environments, offering superior performance where other materials may fail.

Hastelloy B-2 Similar grades

United States: UNS N10665

Germany: W.Nr.2.4819

France: NiMo28

While Hastelloy B-2 is distinct in its composition and properties, there are other alloys within the Hastelloy family and beyond with similar corrosion resistance characteristics:

Hastelloy B-3: Offers improved thermal stability compared to Hastelloy B-2 and excellent resistance to pitting, corrosion, and stress-corrosion cracking in chemical processing environments.

Hastelloy C-276: A versatile, corrosion-resistant alloy that can withstand various chemical environments, including those with oxidizing and reducing agents.

Inconel 625: A nickel-chromium-molybdenum alloy with outstanding strength and corrosion resistance in many acidic and alkaline environments and high-temperature applications.

Monel 400: A nickel-copper alloy known for its excellent corrosion resistance in marine and chemical processing environments, though not as resistant to reducing environments as Hastelloy B-2.

Each of these alloys, including Hastelloy B-2, serves specific industrial needs based on their unique balance of corrosion resistance, temperature stability, and mechanical properties. Hastelloy B-2 is often chosen for its exceptional performance in reducing environments and its integrity in corrosive acids.

Hastelloy B-2 Applications

The exceptional corrosion resistance of Hastelloy B-2 powder, especially in reducing environments, makes it an invaluable material across various demanding applications. Its properties ensure reliability and longevity in sectors where exposure to aggressive chemicals is constantly challenging. Here are the critical applications of Hastelloy B-2:

1. Chemical Processing: Hastelloy B-2 is extensively used in reactors, heat exchangers, and columns in the chemical processing industry. Its resistance to strong acids like hydrochloric and sulfuric acid is crucial for components that come into direct contact with these corrosive substances, ensuring process integrity and minimizing downtime.

2. Petrochemical Production: In the petrochemical sector, Hastelloy B-2 is used for equipment involved in the production and refining processes. Its corrosion resistance is vital for parts exposed to corrosive gases and liquids, contributing to safe and efficient operations.

3. Pharmaceutical Manufacturing: Equipment and components in pharmaceutical manufacturing, including reactors and storage tanks, benefit from Hastelloy B-2’s corrosion resistance. It ensures that process containers and pipelines remain free from corrosion-induced contamination, a critical factor for maintaining product purity.

4. Pollution Control: Hastelloy B-2 finds applications in flue gas desulfurization systems and scrubbers for pollution control. Its resistance to acidic environments helps manage and treat corrosive gases and liquids, thereby supporting environmental compliance.

5. Waste Treatment: In waste treatment facilities, Hastelloy B-2 is used in components exposed to aggressive chemicals during treatment. Its ability to withstand corrosive substances ensures the longevity of equipment used in these harsh conditions.

6. Pulp and Paper Industry: Although less aggressive than chemical processing, the pulp and paper industry also uses Hastelloy B-2 for parts in contact with bleaching agents and other corrosive chemicals used in the paper whitening process.

7. Food Processing: Hastelloy B-2 is sometimes used in food processing equipment requiring high corrosion resistance, especially in system parts exposed to acidic food products or cleaning agents.

Hastelloy B-2 Composition and Properties

Hastelloy B-2, a member of the Hastelloy family of nickel-based superalloys, is engineered for outstanding performance in severe corrosion environments. The alloy's unique composition is the key to its remarkable properties, particularly its resistance to strong reducing acids like hydrochloric acid and sulfuric acid.

Composition:

The chemical composition of Hastelloy B-2 is meticulously balanced to provide exceptional corrosion resistance and durability:

Nickel (Ni): Base, providing overall corrosion resistance and structural integrity.

Molybdenum (Mo): 26-30% significantly enhances resistance to reducing environments and prevents pitting and crevice corrosion.

Chromium (Cr): 1.0% max contributes to oxidation resistance.

Iron (Fe): 2.0% max, adding strength and corrosion resistance to the alloy.

Cobalt (Co): 1.0% max, often added to improve high-temperature stability.

Manganese (Mn): 1.0% max, used to enhance the alloy's mechanical properties.

Silicon (Si): 0.10% max helps refine the grain structure.

Carbon (C): 0.02% max. Reduced carbon content minimizes carbide precipitation during welding to maintain corrosion resistance in weld areas.

Properties:

This composition endows Hastelloy B-2 with a set of distinct properties suitable for challenging industrial applications:

Exceptional Corrosion Resistance: This is especially noted in reducing environments, making it ideal for handling solid acids.

Good Resistance to Stress-Corrosion Cracking: Vital in preventing failure in the presence of tensile stress and corrosive media.

High Durability: Maintains integrity in varying temperatures and corrosive conditions, ensuring the longevity of components.

Weldability: Low carbon content improves weldability, allowing for easier fabrication and maintenance without compromising corrosion resistance.

Applications Stemming from Composition and Properties:

The unique blend of corrosion resistance and mechanical stability makes Hastelloy B-2 the material of choice for various applications, particularly in the chemical processing industry. Its resistance to strong reducing acids is unmatched, making it perfect for reactors, heat exchangers, and other equipment in contact with corrosive substances. The alloy's durability and resistance to stress-corrosion cracking further ensure the safety and reliability of operations in environments prone to aggressive chemical reactions. By leveraging these properties, Hastelloy B-2 enables the development of components that perform reliably under some of the most demanding conditions, enhancing efficiency and safety across various industries.

Hastelloy B-2 Powder Characteristics

The efficiency of Hastelloy B-2 in advanced manufacturing processes, particularly in additive manufacturing, metal injection molding (MIM), and powder compression molding (PCM), hinges on the specific characteristics of its powder form. These characteristics are pivotal for ensuring that the manufacturing process yields parts with optimal mechanical properties and high-quality surface finishes.

Yield Strength:

Yield strength is a measure of the stress at which a material begins to deform permanently. Hastelloy B-2 parts typically exhibit a yield strength of 45,000 to 51,000 psi. This high yield strength underlines the material's ability to withstand significant stress before deforming, making it suitable for high-stress applications in corrosive environments.

Tensile Strength:

Tensile strength represents the maximum stress a material can withstand while being stretched or pulled before breaking. Parts made from Hastelloy B-2 powder can achieve tensile strengths of approximately 100,000 to 110,000 psi. This high tensile strength is crucial for applications where components are subjected to high tensile loads, ensuring durability and performance.

Elongation:

Elongation measures the flexibility of a material or how much it can stretch before it breaks. Manufactured parts from Hastelloy B-2 typically show an elongation range of 40% to 60%, indicating good elasticity. This allows components to undergo significant deformation before failure, which is advantageous in applications requiring materials that can absorb significant energy or withstand impact.

Physical Properties

The physical properties of Hastelloy B-2 powder play a crucial role in its applicability to advanced manufacturing techniques. These properties not only influence the processing and handling of the powder but also significantly impact the performance of the final manufactured parts, especially in corrosive environments.

Density:

Hastelloy B-2 has a density of approximately 9.2 g/cm³. This high density indicates the material's compact atomic structure, contributing to the overall strength and durability of parts manufactured from this alloy. Achieving near-full density in parts is essential for applications requiring high mechanical integrity and resistance to corrosive attack.

Hardness:

Manufactured parts from Hastelloy B-2 powder can achieve hardness levels of about 89 HRB (Rockwell Hardness). This hardness balances strength and flexibility, making it suitable for components exposed to harsh chemical environments where wear resistance and longevity are critical.

Specific Surface Area:

A higher specific surface area of the powder enhances its reactivity and sinterability, which is crucial for processes like Metal Injection Molding (MIM) and additive manufacturing. Hastelloy B-2 powder is engineered to have an appropriate specific surface area to facilitate the sintering process, resulting in parts with high mechanical properties and minimal porosity.

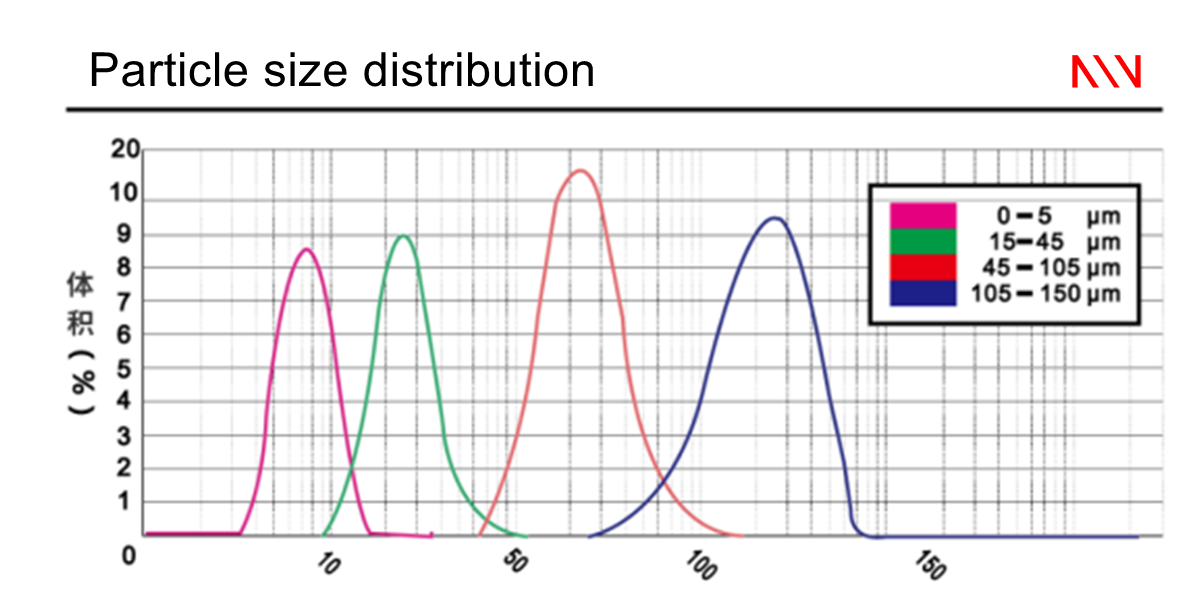

Sphericity:

The sphericity of Hastelloy B-2 powder affects its flowability and packing density, which are essential for manufacturing accuracy and repeatability. High sphericity ensures uniform flow and layering in additive manufacturing processes, contributing to the final parts' dimensional accuracy and surface finish.

Bulk Density:

The bulk density of the powder influences the efficiency of powder handling and the quality of the final part. Hastelloy B-2 powder features an optimized bulk density that facilitates easy handling and efficient compaction, which is essential for achieving uniform part density and strength.

Hall Flow Rate:

This property measures the powder's ability to flow through an orifice, affecting the precision of powder-based manufacturing processes. Hastelloy B-2 powder exhibits excellent flow characteristics, enabling accurate and consistent part fabrication.

Melting Point:

Hastelloy B-2 has a melting point suitable for the specific manufacturing processes it undergoes, typically around 1330°C to 1380°C (2426°F to 2516°F). This melting point ensures the alloy's stability and performance during high-temperature applications.

Relative Density:

After processing, the relative density of parts can reach near theoretical density, which is crucial for achieving optimal mechanical strength and minimizing porosity, thereby enhancing the component's performance in demanding environments.

Recommended Layer Thickness:

For additive manufacturing processes, optimizing the layer thickness is vital to efficiently balancing resolution with build time. Hastelloy B-2 powder is suitable for a recommended layer thickness that ensures fine detail without compromising structural integrity.

Thermal Expansion Coefficient:

The alloy exhibits a thermal expansion coefficient that ensures compatibility with other materials in composite structures, maintaining dimensional stability across a wide temperature range.

Thermal Conductivity:

Its thermal conductivity allows for efficient heat dissipation, vital for components that experience high thermal loads during operation.

Technical Standard:

Hastelloy B-2 powder and its parts adhere to rigorous technical standards, ensuring reliability, quality, and compatibility with international manufacturing requirements.

Manufacturing Techniques With Hastelloy B-2

The exceptional corrosion resistance and mechanical properties of Hastelloy B-2 make it suitable for various manufacturing processes. Each technique offers distinct advantages, depending on the application requirements and desired outcomes. This section explores the compatibility of Hastelloy B-2 with different manufacturing techniques, including 3D printing, metal injection molding, powder compression molding, vacuum casting, hot isostatic pressing, and CNC machining. It also delves into the outcomes of these processes and addresses common issues and solutions.

1. Which manufacturing processes is Hastelloy B-2 suitable for?

3D Printing (Additive Manufacturing): Hastelloy B-2 is particularly well-suited for laser powder bed fusion (LPBF) and direct metal laser sintering (DMLS) techniques. These processes enable the creation of complex components with precise geometries and minimal waste, ideal for specialized applications in harsh chemical environments.

Metal Injection Molding (MIM): This process is advantageous for producing small to medium-sized complex shapes with high precision and excellent surface finish. MIM is cost-effective for high-volume production, making it suitable for parts that capitalize on Hastelloy B-2's corrosion resistance.

Powder Compression Molding (PCM): Suitable for more significant components, PCM can utilize Hastelloy B-2 powder to produce parts with uniform density and good mechanical properties, which is ideal for applications requiring high strength and corrosion resistance.

Vacuum Casting: While less common for high-temperature alloys like Hastelloy B-2, vacuum casting can be used for specific applications, mainly when producing prototypes or small-batch production of complex shapes.

Hot Isostatic Pressing (HIP): HIP is employed to improve the properties of parts made from Hastelloy B-2 powder, especially those manufactured through additive manufacturing or PCM, by reducing porosity and enhancing material density.

CNC Machining: Following initial forming processes, CNC machining is often used to achieve precise dimensions and delicate features on Hastelloy B-2 parts, especially where tight tolerances and smooth finishes are required.

2. Comparison of parts produced by these manufacturing processes:

Surface Finish and Detail Resolution: Additive manufacturing offers unparalleled complexity and detail resolution but may require post-processing for surface finish. MIM produces parts with excellent surface finishes and high dimensional accuracy straight out of the mold.

Mechanical Properties: HIP and PCM can yield parts with superior mechanical properties due to the homogeneous material structure and reduced porosity. Additive manufacturing parts may achieve similar properties with appropriate post-process treatments.

Cost-Effectiveness and Efficiency: MIM is particularly cost-effective for producing large quantities of complex parts, whereas additive manufacturing is more suited for low-volume, high-complexity components where traditional tooling costs are prohibitive.

3. Normal issues and solutions in these manufacturing processes:

Porosity in Additive Manufacturing: Parts produced may exhibit porosity, affecting mechanical properties. Solution: Optimizing process parameters and employing post-process treatments like HIP can significantly reduce porosity and improve part density.

Dimensional Accuracy in MIM: Shrinkage during the sintering phase can impact the dimensional accuracy of MIM parts. Solution: Design adjustments and tooling modifications can compensate for shrinkage, and process optimization can help achieve the desired dimensions.

Surface Roughness in AM: Parts often require post-processing to achieve the desired surface quality. Solution: Techniques such as machining, polishing, or chemical etching can improve surface finish.

Manufacturing With Hastelloy B-2

Main manufacturing processes:

Nickel-based high-temperature alloys are usually used for corrosion resistance, high-temperature resistance, and other extreme working conditions, such as impellers, pump valves, auto parts, etc. Neway has a variety of processing techniques for manufacturing nickel-based high-temperature alloy parts and solving their problems, such as deformation, cracking, and porosity.

Powder compression molding (PCM)

Get A FREE PROTOTYPING SERVICE NOW!: Consultative Design Service at Neway