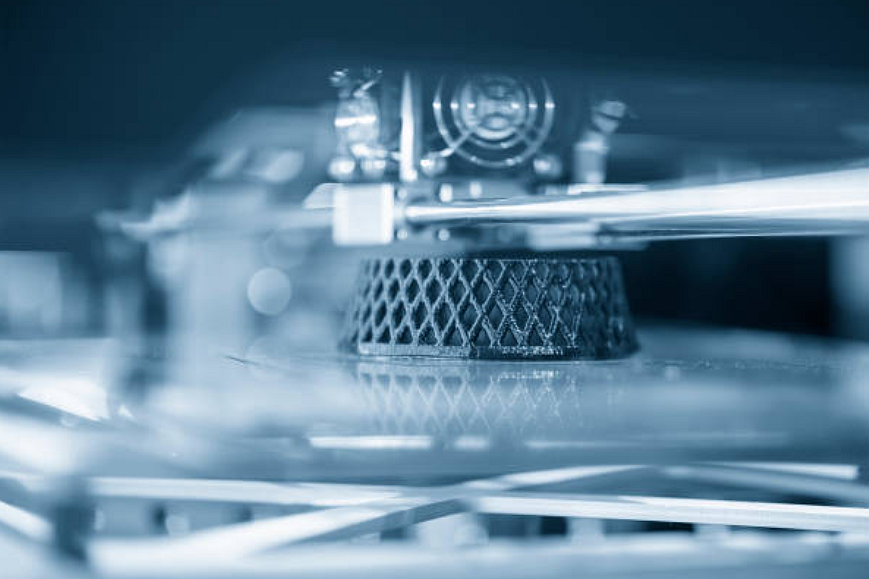

What Are the Materials Available for 3D Printing Service?

In modern manufacturing, 3D printing service has emerged as a revolutionary technology, transforming how we create everything from intricate prototypes to functional end-use parts. This process, also known as additive manufacturing, involves creating objects layer by layer from a digital design file. A critical factor contributing to the versatility and success of 3D printing is the wide range of materials that can be used. This article will delve into the materials available for 3D printing services and highlight their applications, advantages, and how they can be utilized in Neway's production processes.

Plastics and Polymers

Plastics and polymers are among the most common materials used in 3D printing due to their accessibility, versatility, and cost-effectiveness. Some popular types of plastics used in 3D printing include:

PLA Plastic

Polylactic acid (PLA) is a biodegradable thermoplastic made from renewable sources like corn starch or sugar cane. PLA is one of the most common materials used in 3D printing due to its low cost, ease of printing, and range of colors available. It has moderate strength and heat resistance up to 60°C.

ABS Plastic

Acrylonitrile butadiene styrene (ABS) is a durable, versatile engineering thermoplastic widely used across industries. In 3D printing, ABS is valued for its strength, flexibility, machinability, and higher heat resistance up to 80°C compared to PLA. However, it emits fumes during printing.

PETG Plastic

Polyethylene terephthalate glycol (PETG) is a durable, hard plastic with excellent strength and impact resistance. It does not shatter like other thermoplastics. PETG is chemically resistant, food-safe, and easily recycled. It has temperature resistance up to 70-80°C.

Nylon Plastic

Nylon is a popular 3D printing material due to its high strength, durability, flexibility, heat resistance up to 80°C, and smooth finish. Nylon parts also have low friction and naturally resist wear and chemicals. However, nylon absorbs moisture quickly.

TPU Flexible Filament

Thermoplastic polyurethane (TPU) is a rubber-like flexible filament with over 600% elongation. TPU 3D prints are solid and highly resistant to oils, grease, and abrasion. Applications include wearables, phone cases, grips, gaskets, and flexible hinges.

PC Polycarbonate

Polycarbonate (PC) is an extremely strong thermoplastic that can withstand high impacts and heat up to 115°C, making it ideal for functional prototypes. However, PC is difficult to print and sensitive to moisture absorption if not carefully dried before use.

ASA/ABS

ASA is a UV-stable version of ABS with superior weathering resistance. Parts print similarly to ABS but resist fading and cracking better when exposed to sunlight over time. ASA has slightly lower impact strength but higher temperature resistance up to 90°C.

Metals

Selective laser sintering (SLS) and binder jetting 3D printers allow direct 3D printing of metal parts from powder materials. Available metals include stainless steel, titanium, cobalt chrome, aluminum, nickel alloys, and tool steels.

Titanium

Renowned for its exceptional strength-to-weight ratio and biocompatibility, titanium is favored in aerospace, medical implants, and high-performance engineering applications.

Stainless Steel

With variants like 316L and 17-4 PH, stainless steel is versatile and corrosion-resistant, suitable for automotive and medical industries.

Aluminum

Aluminum alloy balances strength and lightweight properties; aluminum is often used for automotive parts, aerospace components, and consumer goods.

Ceramics

Ceramic 3D printing opens up possibilities for creating intricate and heat-resistant objects. Ceramic materials like alumina and zirconia find applications in:

Dental Crowns and Implants

Ceramic 3D printing enables the production of precise dental restorations with biocompatibility and natural aesthetics.

Electronic Components

Ceramic materials with excellent electrical insulation properties manufacture electronics like insulators and capacitors.

Customer Reviews

When prototyping components for his robotics startup, James chose Neway for their expertise in high-quality 3D printing. Their printers achieved remarkable 0.1mm accuracy with difficult geometries. James received completed prototypes in just 2 days. He remarks, "Neway's speed and quality was game-changing for iteratively improving my designs."