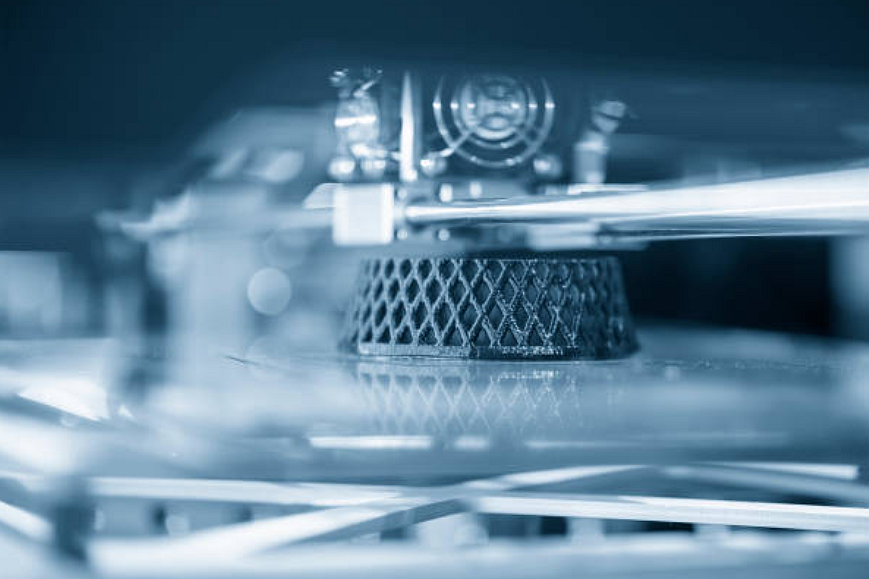

Can 3D Printing Create Functional End-use Parts?

While 3D printing has traditionally focused on prototyping applications, advancements in materials and technologies are enabling functional end-use parts production. 3D printing services can provide durable, high-performance parts for real-world use with the right design approach and material selection.

Plastics for Functional Parts

Engineering thermoplastics like ABS, Nylon, and PC that have good mechanical properties are viable for end-use plastic parts. FDM/FFF can use production-grade thermoplastics. SLS 3D printing offers high-performance materials like nylons and PEBA elastomers suitable for end-use apps.

Metals for Functional Parts

DMLS and binder jetting 3D printing allow high-strength metals like stainless steel, titanium, aluminum, tool steel, and superalloys ideal for functional components. Benefits include lightweight, consolidated assemblies and geometric freedom. Medical, aerospace and automotive industries use metal 3D printing.

Ceramics for Functional Parts

Technical ceramics, including alumina, zirconia, and silicon carbide, can be 3D printed using binder jetting and SLA processes and used to make ceramic cores, shells, and refractory parts with high heat and wear resistance for end-use.

Design Principles

While removing design restrictions, 3D printing still requires an optimized design approach. Wall thicknesses, geometry, support structures, post-processing, static and dynamic loading, and environmental conditions must be considered. Simulation and testing verify performance.

Accuracy and Tolerances

Dimensional accuracy within ±0.2% and tolerances ±0.3 mm are achievable on many 3D printing systems, suitable for various end-use applications. Fine details may require secondary polishing or machining if higher precision or surface finish is needed.

Post-Processing

Most 3D printed parts undergo post-processing like support removal, sanding, drilling and tapping holes, sealing, or coating. Post-processing can improve aesthetics, accuracy, function, and material properties. Some secondary machining may be needed.

Mass Customization

A key advantage of 3D printing is the ease of customization by modifying design files. Small batch production with custom features, shapes, and geometry for end-use is feasible without high tooling costs associated with injection molding.

Consolidated Parts

3D printing can consolidate sub-assemblies into single parts, improving reliability while reducing manufacturing and assembly steps. Lightweighting integrated designs are also possible through topology optimization.

Just-in-Time Production

3D printing enables distributed, on-demand production of spare parts and low-volume components sustainably and locally versus warehousing and shipping finished goods globally. It reduces waste, emissions, and logistics costs.

Limitations

3D printing has slower build speeds than mass production methods. Part size is constrained by printer build volume. Only sometimes the most cost-effective choice for high volumes. Material selection and anisotropic properties also limit use cases.

Applications

End-use applications using 3D printing include custom orthotics and prosthetics in healthcare, UAVs, heat exchangers, and jigs & fixtures in aerospace, personalized consumer goods, automotive ducting, and tooling.

Industry Growth

The production of end-use parts via 3D printing is projected to multiply by over 30% annually as technology and materials improve. Annual revenues from end-use part production are forecasted to reach $14 billion by 2030.

In summary, 3D printing has expanded from prototyping to successfully producing functional end-use parts for many industries by leveraging high-performance materials and optimized designs and integrating them into manufacturing ecosystems. The customization and sustainability benefits are driving adoption. As the technology progresses, many more end-use applications will emerge.

Neway 3D Printing Service

Need impeccable 3D printed parts with complex geometries and premium materials? Get Neway's experts on the job. Their advanced 3D printing consistently delivers tight tolerances and smooth surface finishes. Receive your perfect prototypes fast, and new customers get 20% off!