Aluminum

Basic Description of Aluminum Powder

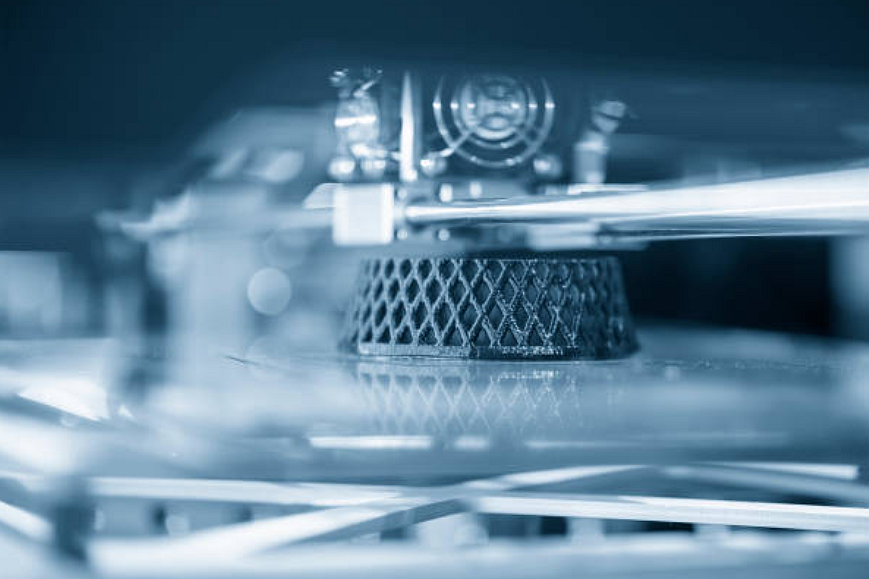

Aluminum powder is a fine granular powder typically used in additive manufacturing and other industrial processes. Renowned for its lightweight and high strength-to-weight ratio, aluminum powder is particularly valued in sectors prioritizing weight reduction without compromising strength. In 3D printing, aluminum powder is often used due to its excellent thermal properties and ability to form detailed, complex structures with high degrees of precision.

The use of aluminum powder in manufacturing is significant due to its reactivity and ability to produce parts through selective laser melting (SLM) or direct metal laser sintering (DMLS). These characteristics make aluminum ideal for producing functional components across various applications, including aerospace, automotive, and consumer goods.

3D Printing Aluminum Grades

Aluminum powders in manufacturing come in various grades, each tailored to specific applications based on their compositional and mechanical properties. Here are a few commonly used grades:

AlSi10Mg: A widely used aluminum alloy in 3D printing, known for its strength, hardness, and thermal properties. It is ideal for parts that require post-processing, such as heat treatment.

AlSi7Mg: is known for its higher flexibility than AlSi10Mg, making it suitable for parts requiring more flexibility and impact resistance. It is commonly used in automotive applications where parts may undergo more dynamic stresses.

7075 Aluminum: This is one of the strongest aluminum alloys available. It is commonly used in applications that require high stress/strain resistance. Due to its zinc content, it offers excellent strength. However, it is less commonly used in powder form due to challenges related to crack sensitivity during printing.

6061 Aluminum: Known for its versatility, 6061 is a heat-treatable alloy with a balance of strength, corrosion resistance, and weldability, making it ideal for engineering and structural applications.

3D Printed Aluminum Applications

Aluminum powder is leveraged across various sectors due to its unique properties that make it suitable for creating lightweight, durable, and complex parts. This section focuses on the specific applications of aluminum powder in 3D printing manufacturing, highlighting its versatility and the diverse industries it impacts.

Aerospace Industry

In the aerospace sector, aluminum powder is used extensively to produce parts that benefit from aluminum's lightweight and robust properties. Components such as brackets, fittings, and fuel nozzles are commonly manufactured using aluminum powder in 3D printing. These parts reduce the aircraft's weight and maintain the strength and corrosion resistance required in high-stress environments.

Automotive Industry

The automotive industry utilizes aluminum powder to manufacture engine parts, transmission components, and chassis elements. Aluminum's ability to reduce vehicle weight is crucial for fuel efficiency and performance. Additionally, the ability to print complex parts on demand revolutionizes automotive manufacturers' inventory and supply chain management.

Medical Devices

In medical manufacturing, aluminum powder creates customized, lightweight prosthetic devices and surgical instruments. The precision of 3D printing with aluminum powder ensures that devices are perfectly tailored to individual patient needs, improving outcomes and comfort. Its biocompatibility and sterilization ability make it ideal for numerous medical applications.

Consumer Electronics

Aluminum powder is integral in producing durable, heat-conductive cases and components for consumer electronics. The material's excellent thermal properties make it suitable for heat sinks, crucial in high-performance electronic devices. Its lightweight nature also contributes to the portability of mobile devices.

Architecture and Construction

In architecture, aluminum powder produces complex facade elements and structural components that benefit from aluminum's resistance to corrosion and aesthetic qualities. Printing parts with intricate designs allows for creative architectural solutions that were previously not feasible or too costly with traditional manufacturing methods.

Energy Sector

For the energy sector, particularly in renewable energy applications like solar panels and wind turbines, aluminum powder is used to manufacture components that require a high strength-to-weight ratio. The material's resistance to environmental stressors ensures long-lasting performance in various climates and conditions.

Aluminum Powders Composition and Properties

Aluminum powder in 3D printing showcases unique characteristics due to its composition, which directly influences its mechanical and thermal properties. This section explores the composition of aluminum powder typically used in additive manufacturing and its consequential properties that make it suitable for various industrial applications.

Composition of Aluminum Powder

Aluminum powder used in additive manufacturing is primarily pure aluminum or an aluminum alloy. The most common alloys include elements such as:

Magnesium (Mg): Enhances strength and improves the elasticity of aluminum, making it more workable and better able to withstand stress without cracking.

Silicon (Si): Increases fluidity and reduces shrinkage in aluminum alloys, which is particularly beneficial in casting processes but also advantageous in 3D printing for achieving finer details and smoother finishes.

Copper (Cu): Generally added to improve hardness and strength, copper can significantly enhance the mechanical properties of aluminum. However, it may slightly reduce its corrosion resistance.

Zinc (Zn): Often added to improve the alloy’s strength, zinc is critical in some high-strength alloys used in aerospace and other demanding applications.

These alloying elements are carefully balanced to achieve desired properties such as improved strength, corrosion resistance, or machinability.

Mechanical Properties

The mechanical properties of aluminum powders can vary based on the specific alloy composition but generally include the following:

Tensile Strength: Aluminum alloys used in 3D printing exhibit tensile strengths that range widely but typically fall between 100 to 700 MPa, making them suitable for structural applications where durability is essential.

Yield Strength: The yield strength of aluminum alloys can vary from about 50 to 600 MPa, indicating the stress at which a material begins to deform permanently.

Elongation: This property measures the material's flexibility, often ranging from 3% to 20%, which indicates good formability and is critical for applications requiring bending and forming.

Thermal Properties

Melting Point: The melting point of aluminum powder depends on the alloy but generally ranges from 450°C to 660°C, which affects the laser parameters and energy requirements in additive manufacturing.

Thermal Conductivity: Aluminum is known for its excellent thermal conductivity, typically around 120-215 W/mK. It is advantageous for applications requiring efficient heat dissipation, such as electronic housing or automotive parts.

Coefficient of Thermal Expansion: Aluminum alloys have a relatively high coefficient of thermal expansion, around 23 x 10^-6 /°C, which must be considered in applications where temperature variations occur.

Aluminum Powder Physical Properties

Understanding the physical properties of aluminum powder is crucial for manufacturers to effectively utilize this material in 3D printing and other manufacturing processes. This section covers essential physical properties of aluminum powder, such as density, hardness, specific surface area, and more, which significantly influence the material's behavior during and after manufacturing.

Density

Density: Aluminum powder typically has a density of approximately 2.7 g/cm³. This relatively low density benefits applications requiring lightweight parts with sufficient strength, such as components in the aerospace and automotive industries.

Hardness

Hardness: The hardness of aluminum powders, particularly those used in 3D printing, can vary but generally falls within the range suitable for machining and post-processing. Aluminum alloys like 6061 may exhibit Brinell hardness values around 95 HB, which helps determine the wear resistance of the final product.

Specific Surface Area

Specific Surface Area: The specific surface area of aluminum powder affects its reactivity and sintering behavior. A larger surface area typically indicates a higher reactivity, which can be crucial for selective laser melting, where rapid sintering is required.

Sphericity

Sphericity: High sphericity in aluminum powder ensures better flowability and uniform layering during printing. This is critical for achieving the final parts' high-quality surface finishes and consistent mechanical properties.

Bulk Density

Bulk Density: The bulk density of aluminum powder, which influences how the particles pack together, affects the stability and integrity of the powder bed in additive manufacturing. Optimal bulk density ensures a steady and predictable build process.

Hall Flow Rate

Hall Flow Rate: This property measures the ease with which aluminum powder flows, which is essential for automated powder handling systems used in 3D printing. A suitable Hall flow rate ensures that the powder can be consistently delivered to the build area without interruptions.

Melting Point

Melting Point: Aluminum powder used in 3D printing typically has a melting point of around 660°C. This property is crucial for determining the processing temperatures and energy requirements in additive manufacturing.

Relative Density

Relative Density: For aluminum powder in additive manufacturing, achieving a high relative density (close to 100%) in printed parts is critical to ensuring their mechanical strength and durability.

Recommended Layer Thickness

Recommended Layer Thickness: In 3D printing, the recommended layer thickness for aluminum powder ranges from 20 to 60 microns, balancing resolution with build time efficiency.

Thermal Expansion Coefficient

Thermal Expansion Coefficient: Aluminum alloys typically have a coefficient of about 23 × 10^-6 /°C, which must be considered during the design phase to accommodate thermal expansion during part use.

Thermal Conductivity

Thermal Conductivity: With a thermal conductivity of around 150-200 W/mK, aluminum powder is excellent for applications requiring efficient heat dissipation, such as electronic housings and automotive cooling systems.

Manufacturing Techniques

Aluminum powder is versatile and can be utilized in various manufacturing processes, each suited to different applications and product requirements. This section explores the manufacturing techniques appropriate for aluminum powder, compares the parts produced by these methods, and discusses common issues along with their solutions.

Which manufacturing processes are Aluminum suitable for?

3D Printing (Selective Laser Melting - SLM and Direct Metal Laser Sintering - DMLS): These techniques are ideal for producing complex, high-precision parts from aluminum powder. They are particularly beneficial for the aerospace and automotive sectors, where the design and production of lightweight, structurally robust components are critical.

Metal Injection Molding (MIM): This process is suitable for high-volume production of small, intricate parts commonly used in consumer electronics and automotive applications. It combines the design flexibility of 3D printing with the efficiency and scalability of traditional molding techniques.

Powder Compression Molding: Used for more extensive, less complex components, this method is cost-effective and suitable for sporting goods and automotive parts manufacturing industries.

CNC Machining: Post-processing parts produced through additive manufacturing often involve machining to achieve precise tolerances and smooth finishes required for functional parts in aerospace and high-precision engineering applications.

Comparison of parts produced by these manufacturing processes

Surface Roughness: 3D printed parts, especially those produced by SLM and DMLS, generally have a rougher surface finish than those produced by MIM or CNC machining, which can achieve smooth surfaces.

Tolerances: CNC machining provides the highest dimensional accuracy and tight tolerances. In contrast, SLM and DMLS can produce complex geometries but might require post-processing to meet stringent tolerance requirements.

Internal Defects: MIM parts tend to have fewer internal defects compared to 3D printed parts, which can exhibit porosity or micro-cracks. However, techniques like hot isostatic pressing (HIP) can improve the density and mechanical properties of 3D-printed parts.

Mechanical Properties: CNC machining does not alter the bulk material properties. At the same time, SLM and DMLS can enhance specific properties through fine microstructural control. However, they may also introduce residual stresses requiring heat treatment mitigation.

Typical issues and solutions in these manufacturing processes

Surface Treatment: To improve the surface quality of 3D printed parts, techniques such as tumbling, sandblasting, or chemical finishing are often employed. Anodizing can also be used to enhance corrosion resistance and surface hardness.

Heat Treatment: Heat treatment processes such as solution annealing and aging are frequently used after 3D printing with Aluminum to relieve residual stresses and improve mechanical properties.

Tolerance Achievement: Achieving tight tolerances with additive manufacturing can be challenging. Additional machining or precision additive manufacturing systems may be required to meet specific dimensional criteria.

Deformation Problems: In processes like SLM, controlling the cooling rates and optimizing the part orientation can help minimize warpage and deformation.

Cracking Problems: Reducing the energy input during laser sintering and optimizing the scanning strategies can help prevent cracking in 3D-printed aluminum parts.

Detection Methods: Techniques such as X-ray tomography, ultrasonic testing, and dye penetrant inspection are used to detect and assess internal defects and ensure part integrity.