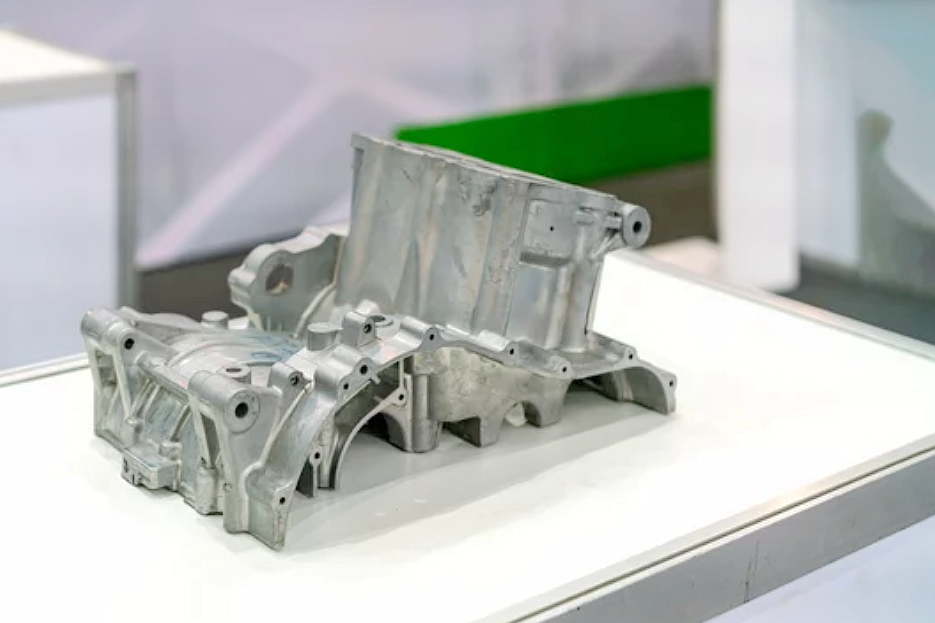

PHILIPS Shaver Shell Deep Cavity Zinc Die Casting

Neway has been a leading manufacturer specializing in customizing metal and plastic parts for over three decades. With a strong focus on delivering precision and excellence, we offer a wide range of manufacturing services, including metal injection molding, die casting, and plastic injection molding. As experts in zinc alloy die casting, we have established ourselves as a reliable partner for companies seeking top-notch zinc cast components. Our dedication to quality and customer satisfaction is exemplified through our successful collaboration with industry giants such as PHILIPS, where we produced a superior zinc alloy casting deep cavity shaver shell.

Projection Introduction

Neway, a manufacturer with an impressive 30-year track record in customizing metal and plastic parts, offers a comprehensive range of services, including metal injection molding, die casting, and injection molding. One of our key areas of expertise lies in zinc alloy die casting. We take immense pride in our successful collaboration with industry giant PHILIPS, wherein we accomplished the production of a zinc alloy die-casting deep cavity shaver shell.

Deep cavity zinc alloy die casting presents a unique set of challenges that require specialized knowledge and technical finesse. However, Neway's proficiency in this field has enabled us to overcome these difficulties and deliver exceptional results. Let's delve deeper into the complexities and how we triumph over them.

Challenges: Deep Cavity Shell Die Casting

Deep cavity shell die casting presents unique challenges that demand the expertise of zinc die casting companies like Neway. With over 30 years of experience in customizing metal and plastic parts, including zinc castings, we are well-equipped to overcome these challenges. Let's explore the difficulties encountered in deep cavity shell die casting and the solutions we offer, including using zinc alloys such as Zamak.

Complex Geometry and Thin Walls

Deep cavity shell die casting often involves intricate designs and thin walls, which require precise replication and dimensional stability. At Neway, our skilled engineers leverage advanced techniques and software to optimize the casting process, ensuring accurate reproduction of complex geometries. Additionally, we utilize zinc alloys with suitable zinc alloy composition, such as Zamak, known for its excellent flow properties and ability to fill intricate molds with thin walls.

Porosity and Shrinkage

In deep cavity shell die casting, the risk of porosity and shrinkage defects increases due to the larger volumes of molten metal. Neway focuses on controlling the cooling rate and optimizing solidification to combat these issues. By carefully monitoring the process and utilizing specific zinc alloys, including Zamak 5, Zamak 3, and Zamak 2, we minimize porosity and shrinkage defects. The controlled solidification of these Zamak alloys contributes to high-quality castings with improved structural integrity.

Use Neway Material Selector for Material selection:

Property | Zamak 2 | Zamak 3 | Zamak 5 |

|---|---|---|---|

Composition | Zn-4Al-1Cu | Zn-4Al-1Cu | Zn-4Al-1Cu |

Tensile Strength (MPa) | 324 | 317 | 331 |

Yield Strength (MPa) | 221 | 207 | 269 |

Elongation (%) | 8 | 2 | 2 |

Brinell Hardness | 60 | 82 | 82 |

Melting Point (°C) | 381-387 | 381-387 | 381-387 |

Density (g/cm³) | 6.6-6.7 | 6.6-6.7 | 6.6-6.7 |

Casting Temperature (°C) | 390 | 380 | 380 |

Fluidity | Moderate to Good | Good | Good |

View Datasheet | Zamak 2 Datasheet | Zamak 3 Datasheet | Zamak 5 Datasheet |

Filling and Venting

Complete and uniform filling of deep cavity shells is essential to avoid voids and ensure part quality. Effective venting is equally important to eliminate trapped gases and porosity. At Neway, we employ advanced moldflow simulation tools to analyze flow characteristics, optimize gating and venting designs, and achieve uniform filling. Zamak alloys, renowned for their superior flow properties, aid in achieving excellent filling and venting characteristics, resulting in high-quality castings.

Tooling and Ejection

Accurate tooling is crucial in reproducing the complex shape of deep cavity shells. Additionally, the ejection of castings from the mold can be challenging due to intricate designs and deep recesses. Neway's experienced tooling engineers utilize advanced techniques and equipment to design and manufacture precise molds that facilitate smooth ejection. By incorporating Zamak alloys into the process, we ensure that the castings exhibit excellent de-mold properties, simplifying the ejection process.

Experience the Difference with Neway

As a reputable zinc die casting company, Neway combines our expertise, state-of-the-art facilities, and the versatility of Zamak alloys to address the challenges of deep cavity shell die casting. Our commitment to high-quality castings sets us apart from zinc die casting companies. Whether you require intricate geometries, thin walls, or precise ejection, Neway has the knowledge, capabilities, and access to a wide range of Zamak alloys, including Zamak 5, Zamak 3, and Zamak 2, to meet your specific requirements.

Top 10 Zinc Die Casting Benefits

Zinc die casting offers several benefits that make it a popular choice for various industries. Here are some key advantages of zinc die casting:

Excellent Casting Properties:

Zinc has low melting and solidification temperatures, which facilitates faster production cycles and reduces energy consumption. Its excellent fluidity enables the casting of intricate and complex shapes with thin walls, intricate details, and tight tolerances.

High Precision and Dimensional Stability

Zinc die casting provides exceptional dimensional accuracy, ensuring consistent and precise parts production. High-quality molds and advanced manufacturing techniques allow for tight tolerances, reducing the need for additional machining operations.

Superior Surface Finish

Zinc die castings exhibit smooth and visually appealing surfaces, requiring minimal finishing or post-processing. The inherent fluidity of molten zinc enables excellent mold filling, resulting in high-quality surface finishes that require little to no additional polishing or plating.

Thin-Wall Capability

Zinc's low melting temperature and excellent flowability enable the production of thin-walled components with consistent wall thickness. This makes zinc die casting ideal for applications where weight reduction is desired without compromising structural integrity.

High Strength and Mechanical Properties

Zinc alloys used in die casting, such as Zamak alloys, offer excellent mechanical properties and high strength-to-weight ratios. They provide sufficient structural integrity for various applications, including automotive, electronics, and consumer goods.

Corrosion Resistance

Zinc alloys are naturally corrosion-resistant, protecting the die cast components from environmental factors. Post-casting treatments, such as chromate or powder coatings, can further enhance corrosion resistance and improve durability.

Cost-Effectiveness

Zinc die casting is a cost-effective manufacturing process due to its shorter production cycles, minimal material wastage, and lower energy consumption. The ability to produce complex shapes in a single operation reduces the need for additional assembly or joining processes, resulting in cost savings.

Sustainable and Recyclable

Zinc is a highly recyclable material, with a recycling rate of over 90%. The recycling process consumes significantly less energy compared to primary production, making zinc die casting an environmentally friendly choice.

Electrical Conductivity

Zinc alloys have good electrical conductivity, making them suitable for applications requiring electrical or electromagnetic properties, such as connectors or housings for electronic devices.

Excellent Post Processing and Surface Finish Properties

Die cast zinc alloy has excellent secondary processing properties, such as CNC machining, drilling, threading, etc. And also has good surface treatment properties, such as plating, oil spraying, PVD, etc.

These benefits make zinc die casting a versatile and attractive option for various industries, offering cost-effective production, high precision, excellent surface finish, and reliable mechanical properties.

Partner With Neway

Partner with Neway, an industry leader in zinc castings and Zamak casting expertise, and benefit from our extensive experience, advanced technologies, and unwavering dedication to quality. Contact us today to discuss your deep cavity shell die casting projects, and let us help you overcome challenges and achieve exceptional results.