Thermal Barrier Coatings: Protecting Custom Parts in High-Heat Conditions

The Critical Role of Thermal Barrier Coatings (TBCs)

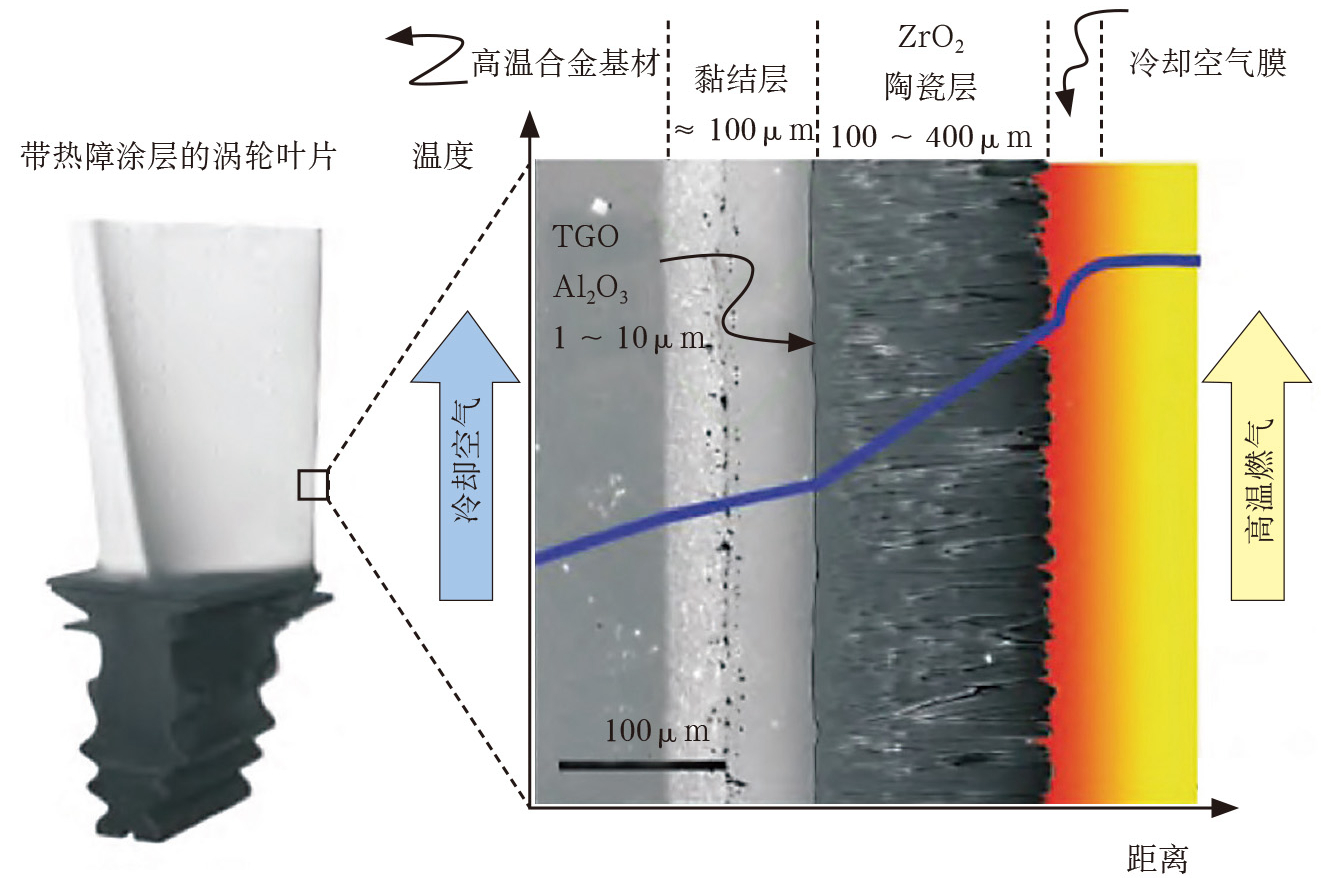

Thermal barrier coatings (TBCs) are advanced ceramic layers applied to superalloys and high-temperature components to insulate them from extreme heat, reducing thermal stress and oxidation. Critical for aerospace gas turbines and power generation systems, TBCs enable engines to operate at higher efficiencies while extending component lifespans.

The global TBC market is projected to exceed $6.5 billion by 2030, driven by innovations in hypersonic vehicles and next-gen turbines. Coatings like yttria-stabilized zirconia (YSZ) meet stringent standards such as AMS 2680 and outperform uncoated parts in thermal cycling by 10x.

The TBC Process: A Step-by-Step Breakdown

Preprocessing Essentials

Surface Roughening: Grit blasting with alumina (Ra 4–6 µm) to enhance adhesion.

Bond Coat Application: Deposit a MCrAlY (M = Ni, Co) layer via plasma spraying to improve ceramic layer bonding.

Core Techniques Compared

TBC Process | Coating Thickness | Key Materials | Application Scope | Advantages |

|---|---|---|---|---|

Air Plasma Spray (APS) | 300–500 µm | YSZ, Gd₂Zr₂O₇ | Turbine blades, combustors | Cost-effective, rapid deposition |

Electron Beam PVD (EB-PVD) | 100–200 µm | YSZ, La₂Zr₂O₇ | Aerospace thermal barriers | Columnar structure, strain tolerance |

Suspension Plasma Spray (SPS) | 50–150 µm | Nano-YSZ, Al₂O₃ | Hypersonic vehicle skins | Ultra-dense microstructure |

Post-Processing & Optimization

Laser Glazing: Smooth surfaces to Ra <1 µm for reduced aerodynamic drag.

Nondestructive Testing (NDT): Use thermal imaging to detect delamination or cracks.

Performance Advantages vs. Limitations

Property | TBC-Coated Parts | Uncoated/Bare Superalloys |

|---|---|---|

Max Operating Temp | 1200–1500°C | 800–1000°C |

Thermal Conductivity | 1–1.5 W/m·K (YSZ) | 15–20 W/m·K (Inconel 718) |

Thermal Cycling Life | 10,000+ cycles (ASTM C633) | 1,000–3,000 cycles |

Erosion Resistance | 5–8x improvement (ASTM G76) | Susceptible to particle impact |

Cost | High initial investment | Lower upfront cost |

Industrial Applications: Where TBCs Excel

Aerospace: Jet engine turbine blades (EB-PVD YSZ coatings).

Energy: Gas turbine combustors (APS YSZ for thermal insulation).

Automotive: Turbocharger rotors in high-performance engines.

TBC Selection Guide

Material Compatibility Matrix

Substrate Type | Manufacturing Process | Recommended TBC Process | Performance Gain Focus |

|---|---|---|---|

EB-PVD YSZ | Thermal insulation, oxidation resistance | ||

APS MCrAlY + YSZ | Hot corrosion resistance | ||

SPS Nano-YSZ | Hypersonic thermal management |

Supplier Evaluation Criteria

Equipment: Vacuum plasma spray systems with ±1% thickness uniformity.

Certifications: NADCAP for aerospace, ISO 14001 environmental compliance.

Surface Finish Technology Matrix

Technology | Main Function | Key Features | Advantages |

|---|---|---|---|

Insulate against extreme heat | YSZ 100–500 µm, 1200°C capability | Enables higher operating temperatures | |

Protect ceramic matrix composites (CMCs) | Mullite/SiC, 50–200 µm | Oxidation and corrosion resistance | |

Minimize clearance in turbines | Al-Si/Polyester, 200–800 µm | Improved engine efficiency |

Technical Suitability: A Four-Dimensional Model

Temperature Resistance EB-PVD YSZ coatings sustain temperatures up to 1500°C, enabling use in hypersonic flight and advanced turbines.

Cost Efficiency Air plasma spraying (APS) offers lower initial costs (~$50–150 per part), while EB-PVD’s durability reduces lifecycle expenses.

Durability Suspension plasma spray (SPS) achieves >80 MPa bond strength (ASTM C633), ideal for high-stress components.

Processing Complexity EB-PVD requires vacuum environments, making it suitable for high-value aerospace applications.

FAQs

How do TBCs differ from environmental barrier coatings (EBCs)?

Can TBCs be applied to titanium alloys?

What causes TBC delamination, and how is it prevented?

How to measure TBC thickness non-destructively?

Are TBCs compatible with additive manufacturing processes?