The Role of Sandblasting in Surface Preparation

Introduction

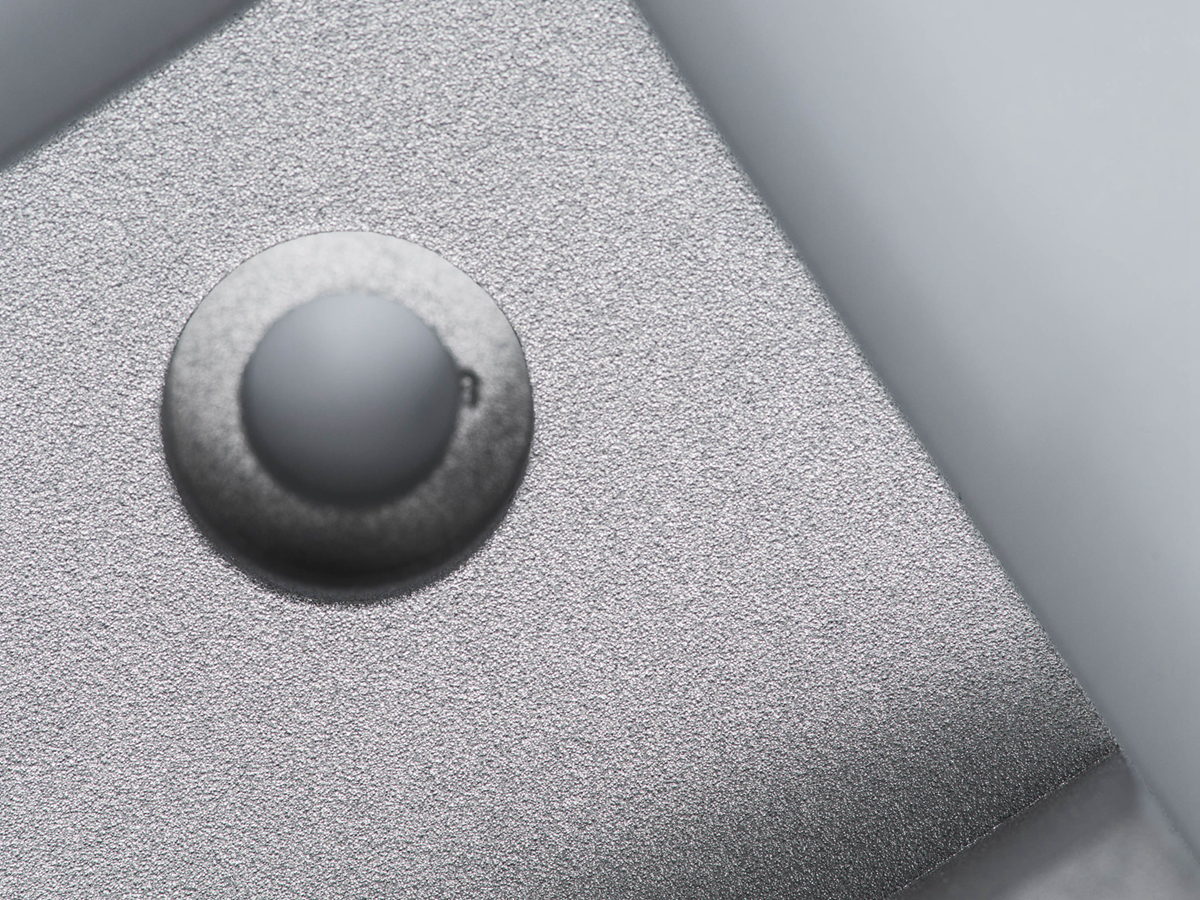

Sandblasting, or abrasive blasting, is crucial for effective surface preparation across industries. Propelling abrasive materials at high velocities efficiently cleans contaminants, creates ideal surface roughness, and significantly improves coating adhesion, durability, and corrosion resistance of finished parts and assemblies.

With growing demand in the automotive, aerospace, and manufacturing sectors, sandblasting technology has expanded rapidly, driven by increased performance standards and the pursuit of higher-quality finishes. Its versatility in addressing diverse materials and substrates makes it indispensable in modern manufacturing processes.

Sandblasting Process Overview

Key Steps in Pretreatment

Surface cleaning and contaminant assessment

Selection of abrasive media (e.g., aluminum oxide, glass beads, steel grit)

Preparation of blasting equipment and safety measures

Comparison of Core Technologies (using tables)

Technology | Abrasive Type | Surface Roughness Achievable | Typical Applications | Efficiency |

|---|---|---|---|---|

Dry Blasting | Aluminum Oxide, Steel Grit | High (Ra 2.0–5.0 µm) | Metal preparation, heavy-duty cleaning | High |

Wet Blasting | Glass Beads, Plastic Abrasive | Medium (Ra 1.0–3.5 µm) | Delicate surfaces, automotive | Moderate-High |

Micro Blasting | Fine abrasive powders | Fine (Ra 0.2–1.5 µm) | Precision parts, electronics | Moderate |

Post-processing and Optimization

Surface inspection and cleaning after blasting

Environmental waste management

Optimization methods for quality improvement and consistency (e.g., media recycling, automated blasting)

Sandblasting: Advantages and Limitations

Brief Introduction: Quick overview of how sandblasting significantly enhances mechanical interlocking for coatings and improves surface corrosion resistance, but may also pose challenges like potential damage to delicate substrates or health hazards if improperly managed.

Property | Advantage / Limitation | Remarks and Typical Values |

|---|---|---|

Mechanical Properties | Enhances adhesion strength | ASTM D4541: Adhesion improved >70% |

Hardness | Not significantly changed | No substantial impact |

Chemical Stability | Neutral, depends on post-treatment | Dependent on coating applied post-blast |

Salt Spray Resistance | Enhanced with proper coating | ASTM B117: ≥ 500–1000 hours achievable |

Oxidation Resistance Temp. | Not directly improved by blasting alone | Requires additional coatings |

Scratch Resistance | Improved coating adhesion increases durability | Up to 2x improvement post-coating |

Industrial Applications of Sandblasting

Examples include:

Automotive Industry Sandblasting in the automotive industry is commonly used for chassis component preparation, enhancing underbody coatings' adhesion and corrosion resistance (increased by 50–75%).

Aerospace Sector In the aerospace sector, sandblasting is essential for cleaning turbine blades prior to applying thermal barrier coatings, improving coating lifetime by up to 40%.

Consumer Electronics For consumer electronics, sandblasting ensures uniform surface finishes essential for subsequent anodizing processes on mobile device casings.

Medical Devices The medical device industry employs sandblasting to achieve precise surface roughness, enhancing sterilization efficiency on surgical instruments.

Sandblasting Process Selection Guide

Material Adaptability Matrix

Substrate Type | Manufacturing Process | Recommended Blasting Process | Performance Gain Focus |

|---|---|---|---|

Dry Blasting | Improved coating adhesion | ||

Micro Blasting | Surface aesthetics | ||

Wet Blasting | Corrosion resistance improvement | ||

Dry Blasting | Coating adhesion & uniformity |

Key Criteria for Evaluating Sandblasting Suppliers

Equipment Capability: Evaluate equipment capacity, abrasive media versatility, and automation for repeatability.

Process Certification: Verify compliance with international standards (e.g., ISO 8501, ASTM standards).

Test Reports: Require detailed adhesion strength reports, roughness measurement, and corrosion resistance test (salt spray ASTM B117) documentation.

Surface Treatment Technology Classification Matrix

Technology | Main Function (Specific & Comprehensive) | Key Features | Advantages |

|---|---|---|---|

Surface cleaning, roughening, adhesion enhancement | Roughness: Ra 1.0–5.0 µm, ASTM D4417 compliant | High efficiency, excellent adhesion | |

Surface smoothing, deburring, corrosion resistance | Surface roughness Ra <0.2 µm achievable | Superior smoothness, excellent corrosion resistance | |

Corrosion resistance, surface hardening, aesthetic finishes | Hardness increased up to HV400, ASTM B117 >1000 hours | Enhanced durability, customizable colors | |

Corrosion resistance, impact resistance, aesthetic finishing | Thickness: 50–150 µm, Impact resistance >100 kg·cm | Durable finish, excellent UV stability |

Technical Suitability Assessment (Sandblasting-Specific)

Four-Dimensional Assessment Model:

Material Compatibility: Suitable for metals, plastics, and ceramics; abrasive media selected based on substrate sensitivity.

Performance Requirements: Achieves precise roughness (Ra 1.0–5.0 µm), significantly enhancing coating adhesion (≥70% improvement, ASTM D4541), and provides superior surface cleanliness.

Process Economics: Cost-effective and high throughput capability; abrasive media recycling reduces material costs.

Environmental and Safety Impact: Requires effective dust control systems, personal protective equipment (PPE), and abrasive recycling systems to comply with ecological (EPA, OSHA) standards.

FAQ (Frequently Asked Questions):

What surfaces are suitable for sandblasting?

Can sandblasting damage metal surfaces?

How is sandblasting performance measured?

What are the environmental impacts of sandblasting?

What standards govern the sandblasting process?