Smoothing And Deburring Custom Parts With Advanced Tumbling Techniques

The Critical Role of Tumbling in Surface Finishing

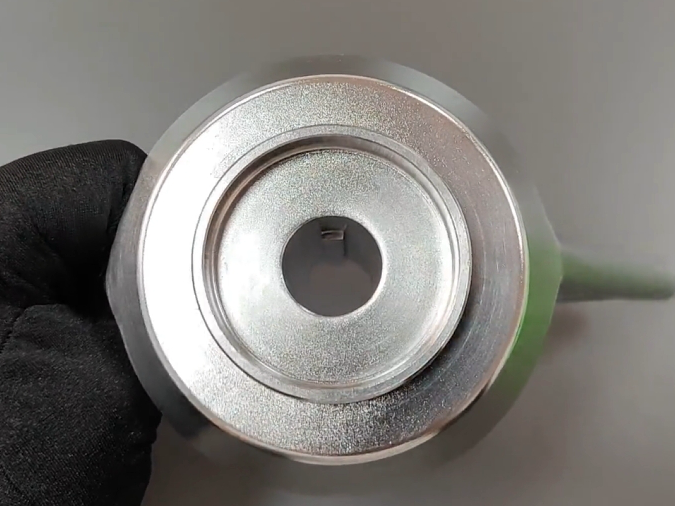

Tumbling (barrel finishing) is a mass-finishing process that smooths edges, removes burrs, and polishes surfaces of metal, plastic, and ceramic parts. Essential for CNC-machined components and die-cast parts, this technique ensures precision and safety in industries like medical devices and aerospace.

The global tumbling media market is projected to reach $1.2 billion by 2028, driven by demand for automated deburring in high-volume consumer electronics and automotive components production. Advanced tumbling complies with ISO 1302 roughness standards and reduces post-processing labor by up to 70%.

The Tumbling Process: A Step-by-Step Breakdown

Preprocessing Essentials

Part Sorting: Group components by material (e.g., stainless steel, zinc alloy) and geometry to optimize media selection.

Deburring Threshold: Define acceptable burr sizes (typically <0.1 mm) using digital microscopes.

Core Techniques Compared

Tumbling Method | Media Type | Key Materials | Application Scope | Advantages |

|---|---|---|---|---|

Vibratory Tumbling | Ceramic cones, plastic pellets | Aluminum, Brass | Small gears, connectors | High throughput, Ra 0.4–1.6 µm |

Centrifugal Barrel Tumbling | Steel pins, walnut shells | Titanium, Stainless Steel | Surgical tools, aerospace fasteners | Precision edges, Ra 0.2–0.8 µm |

Magnetic Abrasive Finishing | Ferromagnetic particles | Complex geometries, thin-walled parts | Medical implants | No media wear, Ra <0.1 µm |

Post-Processing & Optimization

Rinsing & Drying: Remove residual media with ultrasonic cleaners.

Surface Inspection: Validate roughness using profilometers (ISO 4287).

Performance Advantages vs. Limitations

Property | Tumbled Parts | Alternative Deburring Methods |

|---|---|---|

Surface Roughness | Ra 0.1–1.6 µm | Ra 1.6–6.3 µm (manual filing) |

Cycle Time | 30 min–4 hrs (batch-dependent) | 1–8 hrs (laser deburring) |

Edge Consistency | Uniform radii (±0.05 mm) | Variable results (hand polishing) |

Material Removal Rate | 0.01–0.1 mm/hr | 0.5–2 mm/hr (grinding) |

Cost Efficiency | Low labor cost, high media longevity | High labor/machine cost (CNC deburring) |

Industrial Applications: Where Tumbling Excels

Medical Devices: Titanium bone screws polished to Ra <0.4 µm for biocompatibility.

Automotive: Zinc alloy gear components deburred in centrifugal barrels.

Consumer Electronics: Aluminum smartphone casings smoothed via vibratory tumbling.

Tumbling Process Selection Guide

Material Compatibility Matrix

Substrate Type | Manufacturing Process | Recommended Tumbling Method | Performance Gain Focus |

|---|---|---|---|

Vibratory Tumbling | Burr removal, surface smoothing | ||

Centrifugal Barrel Tumbling | Precision edge radiusing | ||

Magnetic Abrasive Finishing | Delicate part finishing |

Supplier Evaluation Criteria

Equipment: Automated tumbling systems with variable speed control.

Media Expertise: Ceramic, plastic, and composite media for diverse materials are available.

Surface Finish Technology Matrix

Technology | Main Function | Key Features | Advantages |

|---|---|---|---|

Mass finishing for deburring and polishing | Ra 0.1–1.6 µm, batch processing | Cost-effective for high-volume production | |

Electrochemical removal of surface layers | Ra <0.1 µm, micro-deburring | Medical-grade smoothness, passivation | |

Precision ablation of burrs with lasers | Ra 0.8–3.2 µm, no media contact | Ideal for complex geometries |

Technical Suitability: A Four-Dimensional Model

Efficiency Centrifugal tumbling processes 50–200 parts per batch in 1–2 hours, ideal for medium-volume aerospace components.

Surface Quality Magnetic abrasive finishing achieves Ra <0.1 µm, meeting stringent medical and optical industry standards.

Versatility Vibratory tumbling handles diverse materials with adjustable media, from soft plastics to hardened steels.

Sustainability Water-based compounds and recyclable media reduce waste compared to chemical-heavy alternatives.

FAQs

How does tumbling differ from electropolishing?

Can tumbling remove internal burrs from complex geometries?

What media is best for polishing titanium parts?

How to prevent part damage during tumbling?

Is tumbling suitable for brittle materials like ceramics?