Essentials of As-Machined Surface Finishes

The Critical Role of As-Machined Surface Finishes

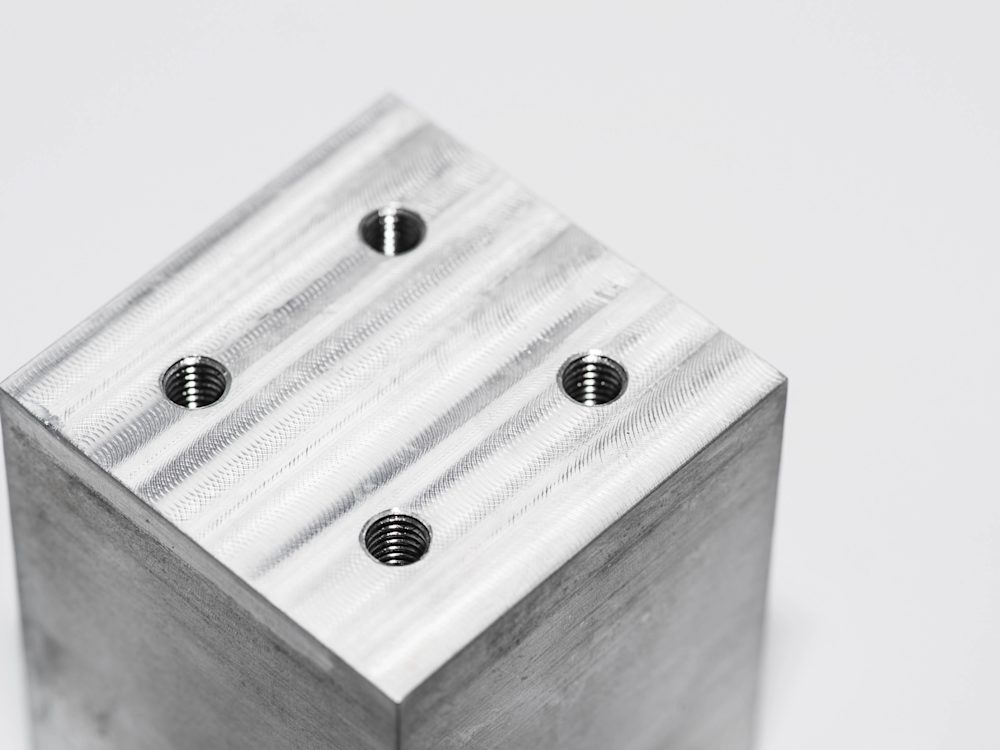

As-machined surfaces are the raw finishes left on parts after manufacturing processes like CNC machining, 3D printing, or precision casting. These unpolished surfaces retain tool marks and are critical for industries like aerospace and medical devices, where rapid prototyping and functional testing demand cost-effective, high-tolerance components.

Valued at over $12 billion globally, as-machined finishes eliminate post-processing costs while delivering precision for materials like titanium alloys and stainless steel. They enable fast turnaround for structural parts in automotive, electronics, and industrial equipment, balancing efficiency with performance.

The As-Machined Process: A Step-by-Step Breakdown

Preprocessing Essentials

Material Selection: Base materials like cast aluminum or powder-pressed alloys are chosen for machinability.

Parameter Optimization: Spindle speed, feed rate, and cutting depth are calibrated to minimize surface roughness.

Core Techniques Compared

As-Machined Process | Surface Roughness (Ra) | Key Materials | Application Scope | Advantages |

|---|---|---|---|---|

CNC Milling | 0.8–3.2 µm | Stainless Steel, Titanium | High-precision aerospace parts | Complex geometries, tight tolerances (±0.01 mm) |

Turning | 1.6–6.3 µm | Aluminum, Brass | Shafts, bushings | High-volume production, cylindrical symmetry |

Grinding | 0.4–1.6 µm | Tool Steel, Ceramics | Medical implants | Ultra-smooth finishes, minimal subsurface damage |

EDM (Electrical Discharge Machining) | 3.2–12.5 µm | Tungsten, Superalloys | Complex geometries | No tool contact, handles hardened materials |

Post-Processing & Optimization

Deburring: Sandblasting removes sharp edges for safety and functionality.

Quality Control: Surface roughness is measured using ISO 1302 standards.

Performance Advantages vs. Limitations

As-machined finishes provide immediate functional surfaces but require trade-offs in environmental resistance compared to post-processed alternatives. Below is a detailed comparison of key properties:

Property | As-Machined Finish | Post-Processed Finish (e.g., Anodizing, Electroplating) |

|---|---|---|

Mechanical Strength | Retains base material’s tensile/yield strength | May alter due to coating adhesion or thermal effects |

Hardness | Matches substrate (e.g., HRC 50–60 for tool steel) | Enhanced via coatings (e.g., HV 800–1200 for PVD coatings) |

Chemical Stability | Susceptible to oxidation and acidic/alkaline exposure | Improved resistance (e.g., anodized aluminum resists pH 4–9) |

Salt Spray Resistance | 24–48 hours (ASTM B117) | 500+ hours (e.g., zinc-nickel plating) |

Oxidation Resistance | ≤300°C (base material dependent) | ≤1200°C (with thermal barrier coatings) |

Scratch Resistance | Low (tool marks prone to visible abrasion) | High (e.g., ceramic coatings achieve 9H pencil hardness) |

Industrial Applications: Where As-Machined Finishes Excel

Automotive: Die-cast aluminum engine brackets (tolerance ±0.05 mm).

Consumer Electronics: CNC-machined prototypes for aluminum casings (Ra 1.6 µm).

Medical Devices: Titanium surgical tools used directly in sterile environments.

As-Machined Finish Selection Guide

Material Compatibility Matrix

Substrate Type | Manufacturing Process | Recommended Process | Performance Gain Focus |

|---|---|---|---|

CNC Milling | Complex geometries, ±0.01 mm tolerances | ||

Turning | High-volume cylindrical parts | ||

Grinding | Ultra-smooth finishes (Ra 0.4–1.6 µm) | ||

EDM | Hardened materials, intricate geometries |

Supplier Evaluation Criteria

Equipment: 5-axis CNC or high-speed machining capabilities.

Certifications: ISO 9001, AS9100 (for aerospace compliance).

Surface Finish Technology Matrix

Technology | Main Function | Key Features | Advantages |

|---|---|---|---|

Direct post-processing-free surface from CNC/3D printing/casting | Ra 0.8–25 µm, retains tool marks, cost-effective | Fast turnaround, no added costs, ideal for prototypes | |

Electrochemical oxide layer formation on aluminum | Ra 0.4–1.6 µm, corrosion resistance (ASTM B117 >500 hrs), dielectric properties | Lightweight, aesthetic colors, enhanced wear resistance | |

Electrostatic application of polymer powder | 50–120 µm thickness, UV/chemical resistance, matte/gloss finishes | Eco-friendly (no VOCs), durable for outdoor use (automotive, power tools) | |

Electrochemical removal of surface micro-irregularities | Ra <0.4 µm, deburring, passivates stainless steel (ASTM A967) | Medical-grade smoothness, hygienic surfaces, reduces friction | |

Thin-film deposition via vacuum sputtering | 1–5 µm thickness, hardness HV 800–3000, temperature resistance ≤800°C | Decorative finishes (gold, black), extends tool life, eco-friendly process |

Technical Suitability: A Four-Dimensional Model

Dimensional Accuracy As-machined surfaces achieve tolerances of ±0.01–0.05 mm (ISO 2768) with roughness ranging from Ra 0.8–25 µm, suitable for functional prototypes. Post-processed alternatives like lapping or electropolishing can refine this to ±0.005 mm and Ra 0.1–0.4 µm.

Cost Efficiency As-machined parts cost 5–50perunitduetominimalprocessing,whereascoatings(e.g.,PVD,thermalbarriers)increasecoststo5–50perunitduetominimalprocessing,whereascoatings(e.g.,PVD,thermalbarriers)increasecoststo20–200 per part.

Environmental Resistance While as-machined surfaces withstand 24–48 hours in salt spray tests (ASTM B117) and ≤300°C, post-processed finishes like anodizing or thermal barriers extend resistance to 500–1000 hours and ≤1200°C.

Lead Time As-machined components are delivered in 1–7 days, while coated parts require 7–21 days for additional treatments.

FAQs

How does as-machined finish compare to anodizing in corrosion resistance?

Can as-machined surfaces meet ISO 13485 medical cleanliness standards?

Which materials are unsuitable for as-machined finishes?

What techniques reduce visible tool marks on as-machined parts?

Is post-processing mandatory for as-machined components in humid environments?