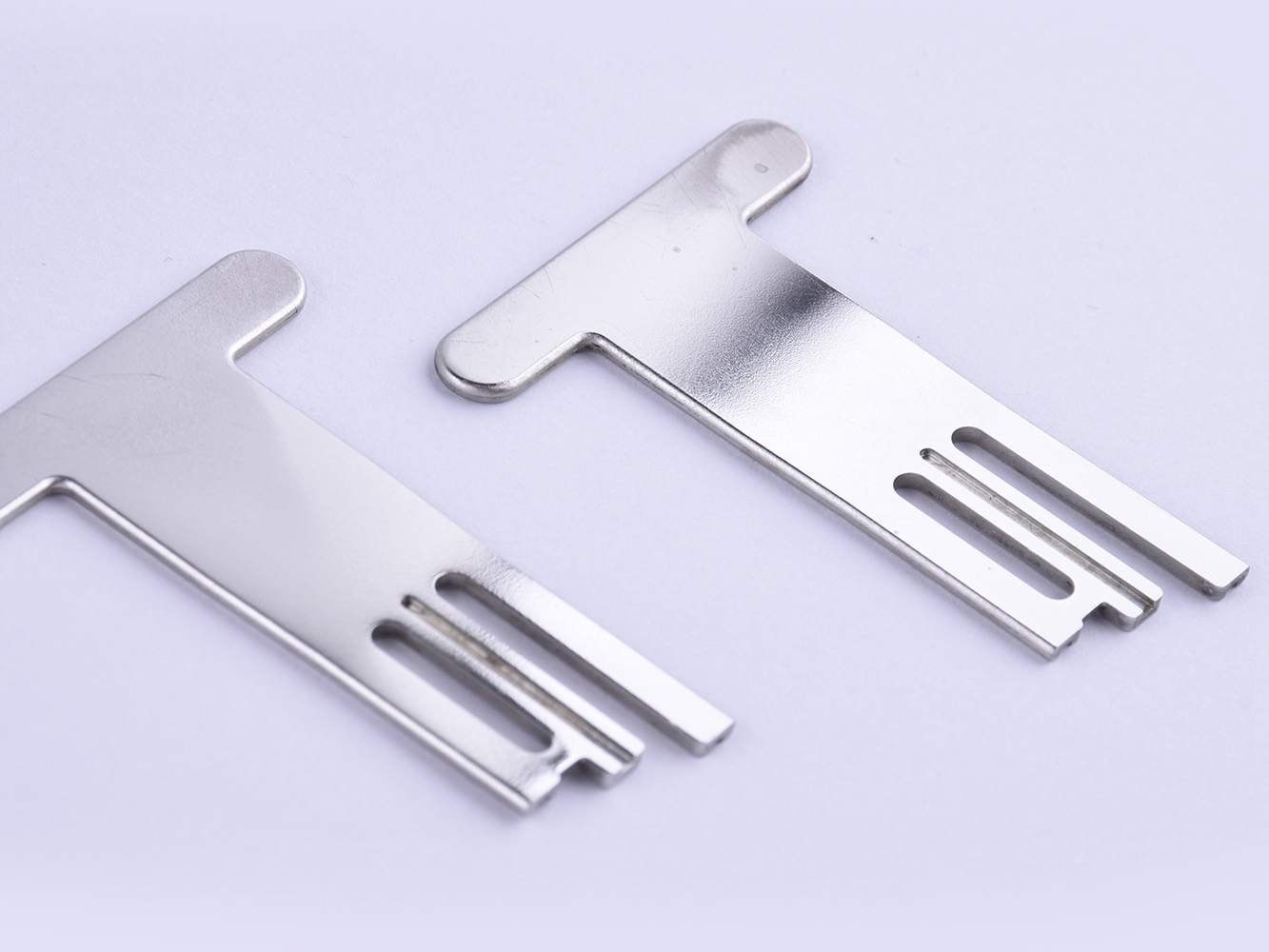

Electropolishing Process for Clean Finishes and Smooth Surface

Introduction

Electropolishing is an advanced electrochemical finishing process that significantly improves surface smoothness, cleanliness, and corrosion resistance. By selectively removing microscopic peaks and surface contaminants through controlled electrolysis, electropolishing delivers a highly reflective, hygienic finish ideal for critical applications in industries like medical, aerospace, and food processing.

Globally, the demand for electropolishing continues to grow, driven by increasing surface quality, hygiene, and corrosion resistance standards. Its ability to consistently deliver precise surface specifications makes electropolishing indispensable in industries where surface integrity directly impacts product reliability, performance, and safety.

Electropolishing Process Overview

Key Steps in Pretreatment

Mechanical cleaning and degreasing of components

Chemical pre-cleaning to remove heavy contaminants

Rinsing to ensure cleanliness before electrolytic processing

Comparison of Core Technologies (using tables)

Technology | Electrolyte Type | Surface Roughness Achievable | Typical Applications | Efficiency |

|---|---|---|---|---|

Standard Electropolishing | Acid-based (Phosphoric/Sulfuric) | Ra <0.2 µm (mirror finish) | Medical implants, aerospace parts | High |

Pulse Electropolishing | Acid-based (Controlled Pulse Current) | Ra <0.1 µm (ultra-smooth) | Semiconductor components, precision parts | Moderate-high |

Electrochemical Deburring | Acidic or Alkaline Solutions | Moderate smoothness (Ra ~0.5 µm) | Complex geometries, industrial fittings | Moderate |

Post-processing and Optimization

Thorough water rinsing and neutralization

Final passivation step to enhance corrosion resistance

Drying and packaging in contamination-controlled environments

Electropolishing: Advantages and Limitations

Brief Introduction: Electropolishing dramatically enhances surface smoothness and corrosion resistance, improving cleanability and product lifespan. However, the process requires precise control of variables and chemical handling, posing operational complexity.

Property | Advantage / Limitation | Remarks and Typical Values |

|---|---|---|

Surface Smoothness | Excellent smoothness achievable | Typical Ra <0.2 µm, mirror-like finish |

Corrosion Resistance | Highly improved via chromium enrichment | ASTM B117 Salt Spray >1000 hours achievable |

Mechanical Properties | No adverse impact | Surface integrity preserved, no weakening |

Chemical Stability | Greatly enhanced post-treatment | Reduced surface reactivity and contamination |

Temperature Resistance | High resistance maintained | Suitable for extreme environments (-200°C to 600°C) |

Scratch Resistance | Moderate improvement | Reduced micro-roughness, improved durability |

Industrial Applications of Electropolishing

Examples include:

Medical Device Industry Electropolishing in the medical device industry enhances cleanliness, reducing contamination risks on surgical instruments and implants (surface contamination reduced >95%).

Aerospace Sector In the aerospace sector, electropolishing is vital for turbine components, improving corrosion resistance and aerodynamic efficiency (surface roughness reduction up to 90%).

Consumer Electronics For high-precision components in consumer electronics, electropolishing ensures precise dimensional tolerances and surface purity essential for microelectronics assembly.

Food Processing Industry The food processing sector employs electropolishing to meet strict hygiene standards by creating surfaces resistant to microbial adhesion (bacterial adhesion reduced by 80–90%).

Electropolishing Process Selection Guide

Material Adaptability Matrix

Substrate Type | Manufacturing Process | Recommended Electropolishing Process | Performance Gain Focus |

|---|---|---|---|

Standard Electropolishing | Enhanced corrosion resistance & hygiene | ||

Pulse Electropolishing | Ultra-smooth surface, bio-compatibility | ||

Standard Electropolishing | Improved surface finish & corrosion resistance | ||

Standard Electropolishing | High-temperature corrosion resistance |

Key Criteria for Evaluating Electropolishing Suppliers

Equipment Capability: Evaluate electrolytic bath size, electrical control systems, and capability for precise process control.

Process Certification: Confirm adherence to international standards (ASTM B912, ISO 15730) and cleanliness certifications for medical or aerospace industries.

Test Reports: Surface roughness reports, salt spray tests (ASTM B117), and purity assessments post-electropolishing are required.

Surface Treatment Technology Classification Matrix

Technology | Main Function (Specific & Comprehensive) | Key Features | Advantages |

|---|---|---|---|

Surface smoothing, deburring, corrosion resistance | Roughness: Ra <0.2 µm, Salt spray resistance >1000 hrs | Ultra-smooth finish, superior cleanliness | |

Surface preparation, roughening | Roughness Ra: 1.0–5.0 µm, ASTM D4417 | High efficiency, good adhesion | |

Surface protection, aesthetics, hardness | Hardness up to HV400, ASTM B117 >1000 hrs | Durable, decorative colors | |

Corrosion protection, aesthetics | Coating thickness 50–150 µm | Impact resistance, UV stability |

Technical Suitability Assessment (Electropolishing-Specific)

Four-Dimensional Assessment Model:

Material Compatibility: Best suited for stainless steel, titanium, cobalt alloys, and nickel-based alloys.

Performance Requirements: Achieves ultra-smooth finishes (Ra <0.2 µm), dramatically enhancing corrosion resistance and cleanliness.

Process Economics: Moderate investment with high-quality output; optimal for critical precision applications.

Environmental and Safety Impact: Requires strict chemical handling, waste management systems, and compliance with EPA and OSHA safety regulations.

FAQ (Frequently Asked Questions):

What materials are suitable for electropolishing?

Does electropolishing affect dimensional accuracy?

What standards regulate electropolishing processes?

How does electropolishing enhance corrosion resistance?

What is the typical surface roughness after electropolishing?